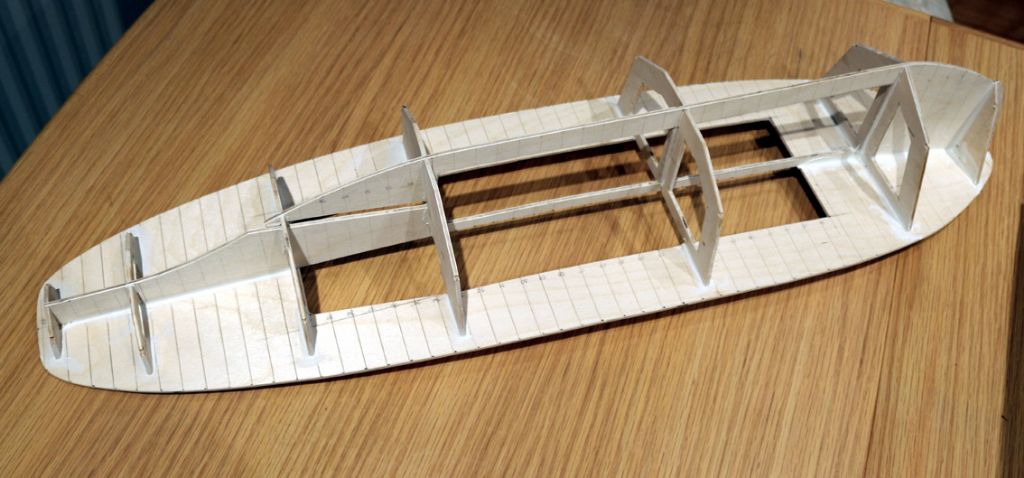

I have now planked the hull – pictures to follow – using 1/8" sheet balsa wood and I think I have seen enough boat build logs on here to be able to complete the waterproof skin e.g., plenty of sanding, filler – probably fibre glass tissue followed by layers of primer and paint etc.

I am looking for tips on how to build, fix and finish the bulwarks because these look as though they might be very tricky to get a neat finish. Does this sound like a good sequence?

1. Sand/ finish the deck whilst there are no obstructions – including its paint finish.

2. Make the mock frame extensions from 1/32"plywood, 42off, paint the same colour as the deck and fix in position using super glue.

3. Cut the bulwarks to shape and paint the inside surface then super glue in position onto the frame extensions.

4. Fit the handrail type capping – probably 1/32" plywood using super glue.

Any other better sequences from experience would be appreciated.

PhilH -….. Happy New Year