Dear All

I have been having some trouble getting the thrusters to turn in unison so decided to strip everything down to see what the problem was, I found that a couple of the thruster feed pipes that go down through the hull hadn't been fitted at 90deg and so were binding on the seals.

Totally my fault for not checking the angles but the strip down did give me the chance to strengthen the plate that the pumps and thruster are mounted on.

The current idea is to increase the towing power by fitting two forward pointing propellers, one on either side of the bow, set in adapted nozzles to send the thrust down each side of the hull.

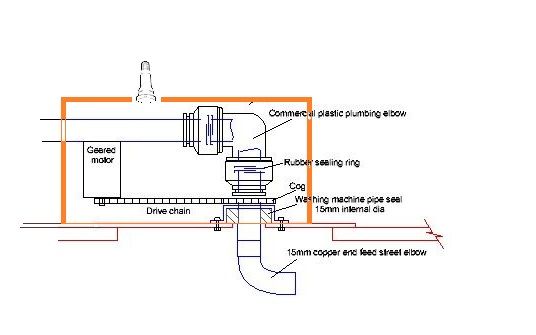

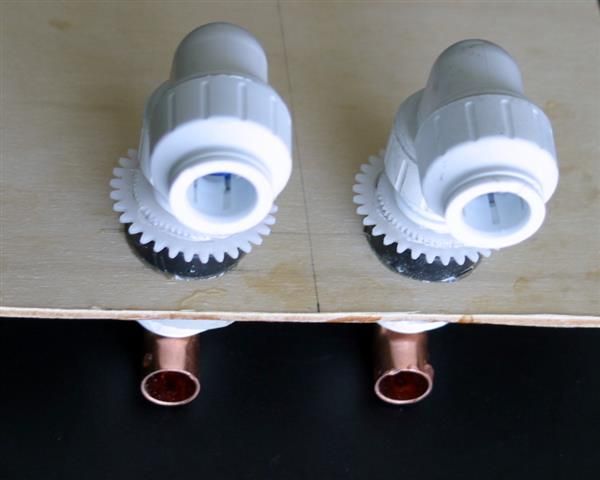

The problem is that the lower hull is now full of thrusters, pumps and main drive motors so the twin 600 size motors for these new propellers will have to be fitted vertically in the forward superstructure with 90deg gearing between the motors and prop shafts.

All be warned that I intend to issue a tug of war challenge at next years Haydock show

Paul

What do you mean 'I must be mad'?