Hello Gareth,

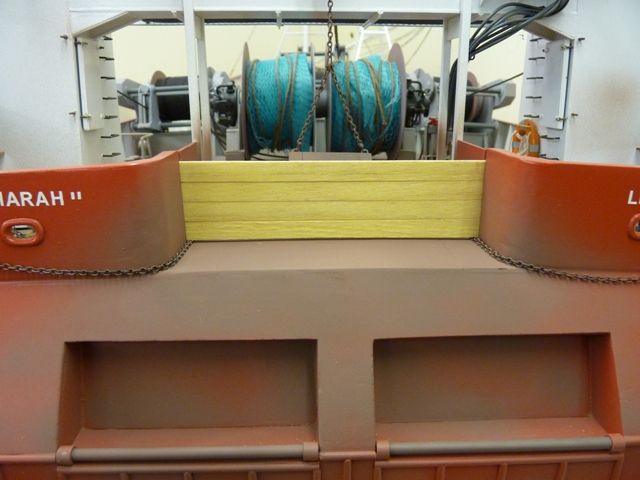

First class work, sould do vey well in model shows worthy of gold medel,

back in the workshop now feeling better but quite of the woods yet,

but junk ready for launch , and started another fishing boat . Kingfisher,…

will the useral plank on frame my scratch build winches and plenty of weathering ,

you mentioned hull trawlers was in the army in the late 50tys and was stationed in hull as a T.A instructor , teaching armoured driving, all sorts of tanks,

used go down the fish dock areas , to local dances had many a good night with the trawler men , all ways had a load of money , and the latest fashoins , and took taxis every where,

this when Hull had fish dock , times where good but hard they earned the money ,

as you say many perished at sea and ther wear many accidents,

all for the price of a cod supper , but at that time fisions fetaliser had nealy 70%

of catches for fish meal,………

still looking for trawel door info……..cheers for now great blog and model …Larry..