The world's leading magazine for all model boating interests

My Triton Build

My Triton Build

- This topic is empty.

-

AuthorPosts

-

18 June 2015 at 18:04 #58567

Dodgy Geezer 1

Participant@dodgygeezer1Well as you can see, I dropped it whilst filling the pin holes etc

You don't need to fill the pin holes. Balsa suffers from handling dents – true, and modern balsa does not seem to be the same hardness all across the sheet, so your hard balsa becomes soft three inches later….

But balsa repays you by being easy to recover. For pinholes, or if you get a dent, put a drop of water on and the wood will swell and recover its original size and shape. See at the bottom of this web page:

18 June 2015 at 18:32 #58568Andy C

Participant@andyc56856Thanks DG. Will remember that for the next round of pinning and gluing. That will be the roofs for the front and rear cabins.

The hull and front / rear decks have had a coat of 50/50 sanding sealer / thinner and are waiting to be rubbed down. Do you think another coat is necessary?

I need to spend some time on the cabin sides, as I was a bit heavy handed with the glue and needs some serious rubbing down before they too can be sealed.

Not sure how to paint the hull. I have some Halfords rattle can grey primer, but would need to buy some other top coat colours or I have some actual full size boat anti-fouling primer and a tin of White undercoat / top coat. I used this on the Goblin and it worked quite well over the ply construction.

What do people think?

Andy

18 June 2015 at 19:07 #58575Dodgy Geezer 1

Participant@dodgygeezer1Micro Viper sits quite nicely on top of the receiver, is this a good idea? Will it get too hot?? Not sure???

At EeZeBilt sizes and powers you are going to be fine.

The gap at the bow is bigger than I originally thought.

Ideally, you glue a thin strip of balsa into any cracks, and sand back when the glue is dry. If you end up with a dips in the skinning that you don't like, glue a flat sheet of balsa over it and sand similarly. It's easy just to add bits to a balsa model – like plasticine!

Hatch in place, fits quite tight actually, if a little wonky.

If you want a thinner top to the hatch, try a piece of card. When sealed it will be quite waterproof.

What do other people use, I have seen some using normal wood PVA, blue or green, but is there a real preference?

Everyone has their own preference. I like the original balsa cellulose cement…

Edited By Dodgy Geezer on 18/06/2015 19:07:21

Edited By Dodgy Geezer on 18/06/2015 19:07:33

18 June 2015 at 19:15 #58576Dodgy Geezer 1

Participant@dodgygeezer1Thanks DG. Will remember that for the next round of pinning and gluing. That will be the roofs for the front and rear cabins.

It will look like magic to you! Even works for quite big dents. Just remember to do it before any sealing…

The hull and front / rear decks have had a coat of 50/50 sanding sealer / thinner and are waiting to be rubbed down. Do you think another coat is necessary?

Depends a lot on the absorbency of the balsa. I usually do 2 or three coats, then a primer spray to show me where the irregularities are. But then I don't use tissue..

Not sure how to paint the hull. I have some Halfords rattle can grey primer, but would need to buy some other top coat colours….

There are so many paints available, and some don't work well with others and react badly. So the usual advice is to stay with one manufacturer, and if you don't, spray a test piece to check paint compatibility before doing the whole hull.

I use Halfords rattle cans, and finish with a spray of matt clear lacquer.

Edited By Dodgy Geezer on 18/06/2015 19:16:39

18 June 2015 at 19:23 #58577Dodgy Geezer 1

Participant@dodgygeezer1Anyway Didn't came up, and as you know it is short for did not, so can you use it in the sentence above? "You did ask did not you".

You missed out a question mark!

Punctuate the following:

'Tom had had while Dick had had had had had had had the teacher's approval.'

2 March 2016 at 19:17 #63713Steve Walker 1

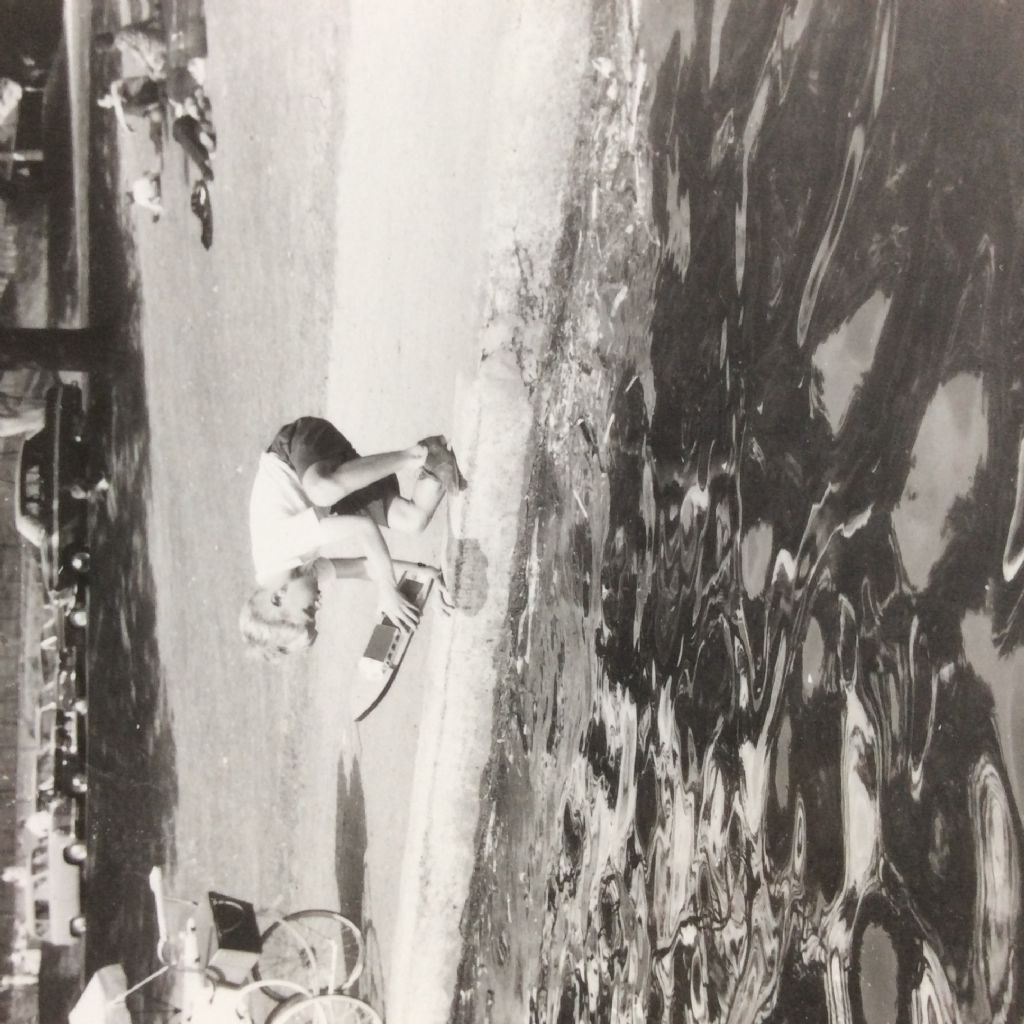

Participant@stevewalker1Hello, In the early 1960's, see photo, I had a Triton type model which I loved. My granddaughter now wants to build one just like it. No problems with balsa etc. however time has clearly moved on in relation to power. Because of the likely use, I want to replicate the original set-up, ie small electric motor, clips and a battery. It is highly probable that this will become an ornament rather than a working model.

I have read many threads and am still a bit mystified. I feel quite capable of making rudder and using brass tube and rod for prop but I saw in Andy's pics that he had what seemed to be a prop shaft with bearings.

Can anyone suggest a motor, prop shaft and battery system that would suit the Triton without RC being involved?

2 March 2016 at 21:50 #63716Dodgy Geezer 1

Participant@dodgygeezer1Posted by Steve Walker 1 on 02/03/2016 19:17:29:Hello, In the early 1960's, see photo, I had a Triton type model which I loved. My granddaughter now wants to build one just like it. No problems with balsa etc. however time has clearly moved on in relation to power. Because of the likely use, I want to replicate the original set-up, ie small electric motor, clips and a battery. It is highly probable that this will become an ornament rather than a working model.

I have read many threads and am still a bit mystified. I feel quite capable of making rudder and using brass tube and rod for prop but I saw in Andy's pics that he had what seemed to be a prop shaft with bearings.

Can anyone suggest a motor, prop shaft and battery system that would suit the Triton without RC being involved?

A very evocative picture! Can I put it up on the EeZeBilt web site?

I suspect that EeZeBilts spent most of their time as shelf ornaments in a kids bedroom – they are the correct size for this – but of course R/C adds another dimension to the fun a young kid can have. Which is why we have the 50+ range…

However, if you want an original experience, all the EeZebilts used the same 5 1/2" 'brass tube and prop without bearings. This would have added quite a lot of friction, particularly if the tube got bent a bit! But then the hull was not designed for high speeds.

The Triton is the biggest of the original EeZebilts, and would have taken a small 3-6v brushed motor about 3-4cm lomg. You can get these for the equivalent of a few shillings on ebay – here's an example **LINK**

Model shops don't seem to sell so many of these cheap motors nowadays, but you might consider the Graupner Speed 260 or the MFA RE-380 from Cornwall Model supplies. The EeZebilt website gives a reference to the Graupner M2 prop shaft range if you want a shaft with bearings – you want the 409 M2 Propshaft with Tube 150mm here **LINK**

For batteries I would use 4 Nimh cells – perhaps these? **LINK**

Hope this helps – we'd love to see pictures of the build. A child of about 8-9 should be able to build the boat by herself if an adult cuts the parts out….

3 March 2016 at 07:32 #63717Steve Walker 1

Participant@stevewalker1Thanks very much for this. I should perhaps have said that my remote location means that I have to order things online and, since the postage normally costs twice what the items cost, I didn't want to buy a pup.

This will be an Easter holiday project I think and we will certainly take some pics.

The photo of a rather handsome me was taken at the Duthie Park in Aberdeen in 60 or 61 I guess and feel free to do what you like with it. I believe the Council might have recently refurbished the pond but I'm not certain.

Thanks again and we will let you know how we get on. I probably should say too that if she likes doing this I will probably start annoying you about remote control.

I have built and sailed small yachts in the past, 60's/70's this time, but used the Braine system. Are there still enthusiasts for this ? We used to chalk a mark on the other end of the pond and see who landed closest…..oh happy days!

3 March 2016 at 13:02 #63727Dodgy Geezer 1

Participant@dodgygeezer1Thanks very much for this. I should perhaps have said that my remote location means that I have to order things online and, since the postage normally costs twice what the items cost, I didn't want to buy a pup.

The EezeBilt series was designed for 'pocket-money' – so the lowest possible cost is a design requirement. Nowadays that is best achieved by online buying, though the quality of what you get often matches the price! There are some links to places I used on the web-site **LINK** – but these are old and some of the links will be dead…

This will be an Easter holiday project I think and we will certainly take some pics.

Have you seen this video of a (somewhat older) kid making an EeZeBilt? **LINK**

I have built and sailed small yachts in the past, 60's/70's this time, but used the Braine system. Are there still enthusiasts for this ? We used to chalk a mark on the other end of the pond and see who landed closest…..oh happy days!

Try **LINK**

7 March 2016 at 09:29 #63771Steve Walker 1

Participant@stevewalker1Hello again. I built a prototype on Saturday to ensure that when I build this at Easter with my granddaughter I won't have any unexpected problems. Unlike many I can't nip to a model or hobby shop and I have just discovered that postie won't deliver balsa glue. Anyway, the hull is very thin. Will seal and sand type product harden it or do I need to add tissue. When looking at some sites I note that (aero) modellers shrink it. I imagine this would pull the tissue off the nice curve I have in the hull. What to do for best, please?

7 March 2016 at 10:38 #63773Dodgy Geezer 1

Participant@dodgygeezer1Posted by Steve Walker 1 on 07/03/2016 09:29:16:Hello again. I built a prototype on Saturday to ensure that when I build this at Easter with my granddaughter I won't have any unexpected problems. Unlike many I can't nip to a model or hobby shop and I have just discovered that postie won't deliver balsa glue. Anyway, the hull is very thin. Will seal and sand type product harden it or do I need to add tissue. When looking at some sites I note that (aero) modellers shrink it. I imagine this would pull the tissue off the nice curve I have in the hull. What to do for best, please?

No glue posted? Interesting… What happens if you buy a tube and have it posted, as most model shops will do – here is the page from the shop I used, but pretty well anywhere has the same 'shopping cart'…? **LINK**

The balsa skin on EeZeBilts is indeed thin – 1/16" or 1.5mm – which was fine for small boats and cheap kits. You are usually encouraged to use HARD balsa for this part – soft balsa would soon pick up unsightly dents, and would probably crumble with repeated handling. So you must certainly use a hardish balsa for the skin, and support it well from the inside…

For the larger 50+ series, and certainly if you are going to 'double-up' the size (as a number of people do) it's a good idea to consider 1.5mm ply for the skin. But that harder-to-cut wood makes the boat less suitable for an outright beginner or child.

I find hard balsa with several sanding-sealer coatings produces a reasonably robust finish (though an all-balsa boat will always suffer from knocks with a hard object!). However, many people swear that a covering improves things immensely, and that advice is frequently found in modelling books – I have a comment on it in the web site here : **LINK**

I have tried to use this technique before a number of times, but I don't seen to get on with it. The tissue never lies flat for me, it ridges and lifts, ruining a perfectly good surface! But for many people, it is the best way to produce a smooth base to paint on. You can also make a much more robust surface, skinning with fibreglass and resin, or various epoxy skinning products. Nylon stockings can be used as covering… but, given my incompetence in this field, I have stayed away from experimenting with these on a newly-finished hull.

I am sure that a host of people will now join in, explaining their own personal preference for skinning, and explaining what I am doing wrong. Many will be much more skilled and experienced than I – so it will be worth listening to what they have to say…

7 March 2016 at 11:29 #63774Steve Walker 1

Participant@stevewalker1Think the glue issue is because mail comes by air. When I type in my HS postcode it sets off bells.

Some food for thought there. I wasn't aware of hard and soft balsa. All mine must be soft. Easy to cut but easy to crack too. Can you order it by type or just buy loads and hope you get a mix. I'm now thinking of trying several things on the hull before Ava arrives. Might try glassfibre sheet and resin inside front wall where I can still reach with a long paintbrush. I will try tissue on a section outside and I'm wondering about just cutting an access hatch on floor then pouring in some sealant and swishing it around. I am thinking that I might pre-dress some sections before we build the next one. I might also cut out some extra supports and/or try some 1.5 ply if I can find any.

When I looked at the EeZebilt links I thought perfect, but cannot seem to open up the whole comment. I tried flipping the bottom left corner to open a page but zilch… What am I doing wrong? Also having trouble with pics on my iPad so I'm going back to faq's on my laptop.

7 March 2016 at 12:21 #63775Dave Milbourn

Participant@davemilbourn48782Tissue works for me. Try this way **LINK**

Dave M

7 March 2016 at 12:22 #63776Dodgy Geezer 1

Participant@dodgygeezer1Hmm… some food for thought here indeed! I have never had paint or glue specified as 'dangerous' – though modern safety rules are pretty much out of control nowadays! Amazon, for instance offers a pack of the DUR glue from Stockton Modellers – I want to their web site here **LINK** and was able to submit a made-up address in Stornoway quite acceptably for some balsa glue…

Balsa is graded from hard-medium-soft. In the old days you would chose your own balsa from a modelling shop and get just the density you wanted. I get mine cheaply off Ebay and sort it at home – there's usually a mix of grades. Annoyingly, modern balsa seems to be of varying quality, and you can get one part of a sheet soft while another part is hard…

If you want quality goods, I have heard nothing but good reports about SLEK – a very old name in the modelling field – **LINK** You may want to talk to them about wood and glues – since you don't only have to use Balsa Cement – aliphatic resin or PVA are also commonly used. And I see they have a wide selection of hardening and skinning products as well…

You don't need an access port if you have a hypodermic – but take care to note this awful warning – http://eezebilt.tk/rafpics4.html

When I looked at the EeZebilt links I thought perfect, but cannot seem to open up the whole comment. I tried flipping the bottom left corner to open a page but zilch… What am I doing wrong?

It's probably something I'm doing wrong – all those pages are coded manually by me when I was trying to learn how to put a web site together… send me the address of the page you don't like and I'll see what the problem is…

Edited By Dodgy Geezer on 07/03/2016 12:22:41

Edited By Dodgy Geezer on 07/03/2016 12:30:36

7 March 2016 at 17:14 #63777Steve Walker 1

Participant@stevewalker1Thanks very much for this, chaps. Now extremely jealous of Daves finishes. I think Ava will be patient enough to achieve this sort of result…NOT!

I'm glad I started this with a month to spare, I think I'll need it all to get ready so that we bash straight on. I had better take up this boat building more seriously now, the missus is already wondering why I am collecting the same amount of equipment as I used to build our house – except it's smaller.

The link was the last one you sent, Dodgy, the one to hints and tips on the EeZebilt pages.

7 March 2016 at 18:09 #63778Dodgy Geezer 1

Participant@dodgygeezer1The 'Hints and Tips' don't have any more data associated with them – what you see is what you get. The whole comment on tissue covering reads:

"When I have sheet areas around my models I bond on tissue. It's quite easy, and is a well established process:

Give the hull 2 or 3 coats of dope, sanding between each coat (not too critical to get a great finish). Cut tissue panels oversize – quite large bits can be used, the entire deck can be from one bit, and then other bits for the hull sides, and bottoms.

Damp the tissue by laying it on a worktop and soaking with a sponge. Put the damp tissue in place on the boat and then flood through with neat cellulose thinners.Because the tissue is damp it will take on compound curves, and the thinners will activate the dope coats and pull the thinned dope into the tissue.You can then complete with a couple more coats of dope, sanding between coats, but because the wood grain has gone, again this is quick and easy."

Dave's link provides a lot more detail…

Edited By Dodgy Geezer on 07/03/2016 18:10:01

7 March 2016 at 18:40 #63779Dave Milbourn

Participant@davemilbourn48782I have today sent Colin a much-revised article for the MB website. This includes details of my methods for using glass cloth with Eze-Kote and ZAP Epoxy Finishing Resin as well as tissue and sanding sealer.

I know there are certain learned individuals who don't favour covering at all, but for small models I've found it to be much the best option. As the article says, it's not the only way but it works for me.

This article will appear in due course and I'm sure CB will give it a tease when he's done the deed!

Dave M

7 March 2016 at 18:50 #63780Andy C

Participant@andyc56856I really must get on with my build, put a first coat of undercoat on after sanding sealer, rub down and repeat. I will update the post with pictures soon.

Andy

7 March 2016 at 20:31 #63781Dodgy Geezer 1

Participant@dodgygeezer1Posted by Andy C on 07/03/2016 18:50:08:I really must get on with my build, put a first coat of undercoat on after sanding sealer, rub down and repeat. I will update the post with pictures soon.

Andy

You will find that this is the time you can make or mar your final handiwork. Concentrate carefully, and take advice from the experts in order to achieve a perfect finish. Since I am very experienced in this field, I will describe the stages I go through when finishing off a hull. Of course, you will not find it as easy as I do when you start, but after about 30 years you should be able to approach my levels of perfection…

1 – Rub down hull with medium sandpaper. Take too much off at the chine. Glue a new piece on.

2 – Rub down with fine sand paper. Find that cutting the new piece to shape is taking ages. Switch to medium and finish chine off nicely. Find that I've cut groves out of the transom instead.

3 – Give up on glueing extra bits in, and fill groves with knifing filler.

4 – Rub down with fine sandpaper. Find that knifing filler clogs the paper so much that I run out of it.

5 – Eventually get the surface satin smooth. Give a coat of thinned sanding sealer. Solvent loosens a joint, so I pin it back, and then fill the bumps with more filler.

6 – Sand sealer down again, and find that I've sanded it all off. And the surface is worse than before…

7 – After several coats of sealer, attain a nice smooth finish. Wash lightly with water with a drop of detergent and leave to dry.

8 – Surface looks good the next day. Spray with Halfords primer. Surface now looks misshapen and rough, as the primer accentuates the irregularities.

9 – Sand down with finishing paper and respray. Surface looks a bit better. Pick it up too early and get a thumbprint right in the middle of the flattest part.

10 – Sand down and respray several times. Now it's looking good. Assemble hull to see what it will look like, and find out that the hatches no longer fit in their places due to extra paint thickness.

11 – Retrim hatches, and respray. Leave for a day to dry.

12 – Turn upside down and spray hull with red undercoat. Looks good on the bottom. But the sides now have runs on them.

13 – Sand runs back to bare wood and redo primer.

14 – Mask the red undercoat and spray the sides. Put it on the garden bench to dry, and find that the wind is blowing the dust all over that bench today..

15 – Sand off the dust, and respray the sides. Peel off the masking tale. Half the red undercoat comes off with it…

16 – Fill the gap left by the missing paint, sand and respray.

17 – Mask the hull and spray the superstructure. Find that I haven't masked properly, and there is overspray on the deck.

18 – Try to wipe the overspray off with thinners. End up mixing both paints so that there is a curious blotch of purple across the deck.

19 – Remove as much purple as I can with fine sandpaper, mask the affected area and spray gently. Seems to cover the blotch.

20 – Put a finishing lacquer spray over the whole boat. The lacquer solvent washes away the deck paint and reveals the purple blotch again……and they say that hobbies are relaxing….!

Edited By Dodgy Geezer on 07/03/2016 20:32:14

7 March 2016 at 21:32 #63783 Colin BishopModerator@colinbishop34627

Colin BishopModerator@colinbishop34627You can see Dave's revised article here:

I have also 'bumped' it up the article list on the Home Page.

Colin

8 March 2016 at 12:38 #63789Steve Walker 1

Participant@stevewalker1I never imagined that my little Triton, which has cost me £8 so far, would generate the help and comments it has so far. I am very grateful, but also glad I didn't let Dodgy near my house build. Good laugh tho' and I will try to bear the lessons in mind as I finish my model.

After all this, if Ava arrives at Easter and decides she wants a glider instead of a boat she may end up with a size 43 up her butt.

Thanks all, Steve.

8 March 2016 at 16:06 #63794Andy C

Participant@andyc56856Posted by Dodgy Geezer on 07/03/2016 20:31:41:Posted by Andy C on 07/03/2016 18:50:08:I really must get on with my build, put a first coat of undercoat on after sanding sealer, rub down and repeat. I will update the post with pictures soon.

Andy

You will find that this is the time you can make or mar your final handiwork. Concentrate carefully, and take advice from the experts in order to achieve a perfect finish. Since I am very experienced in this field, I will describe the stages I go through when finishing off a hull. Of course, you will not find it as easy as I do when you start, but after about 30 years you should be able to approach my levels of perfection…

1 – Rub down hull with medium sandpaper. Take too much off at the chine. Glue a new piece on.

2 – Rub down with fine sand paper. Find that cutting the new piece to shape is taking ages. Switch to medium and finish chine off nicely. Find that I've cut groves out of the transom instead.

3 – Give up on glueing extra bits in, and fill groves with knifing filler.

4 – Rub down with fine sandpaper. Find that knifing filler clogs the paper so much that I run out of it.

5 – Eventually get the surface satin smooth. Give a coat of thinned sanding sealer. Solvent loosens a joint, so I pin it back, and then fill the bumps with more filler.

6 – Sand sealer down again, and find that I've sanded it all off. And the surface is worse than before…

7 – After several coats of sealer, attain a nice smooth finish. Wash lightly with water with a drop of detergent and leave to dry.

8 – Surface looks good the next day. Spray with Halfords primer. Surface now looks misshapen and rough, as the primer accentuates the irregularities.

9 – Sand down with finishing paper and respray. Surface looks a bit better. Pick it up too early and get a thumbprint right in the middle of the flattest part.

10 – Sand down and respray several times. Now it's looking good. Assemble hull to see what it will look like, and find out that the hatches no longer fit in their places due to extra paint thickness.

11 – Retrim hatches, and respray. Leave for a day to dry.

12 – Turn upside down and spray hull with red undercoat. Looks good on the bottom. But the sides now have runs on them.

13 – Sand runs back to bare wood and redo primer.

14 – Mask the red undercoat and spray the sides. Put it on the garden bench to dry, and find that the wind is blowing the dust all over that bench today..

15 – Sand off the dust, and respray the sides. Peel off the masking tale. Half the red undercoat comes off with it…

16 – Fill the gap left by the missing paint, sand and respray.

17 – Mask the hull and spray the superstructure. Find that I haven't masked properly, and there is overspray on the deck.

18 – Try to wipe the overspray off with thinners. End up mixing both paints so that there is a curious blotch of purple across the deck.

19 – Remove as much purple as I can with fine sandpaper, mask the affected area and spray gently. Seems to cover the blotch.

20 – Put a finishing lacquer spray over the whole boat. The lacquer solvent washes away the deck paint and reveals the purple blotch again……and they say that hobbies are relaxing….!

Edited By Dodgy Geezer on 07/03/2016 20:32:14

Now I know what not to do, when finishing her off. I went to my local marina on the Thames and bought a big tin of anti-fouling undercoat and a further tin of stuff that can be used as another undercoat to be top coated or left as is. Anti-foul is a grey/silver colour and rubs down nicely, two coats gives a great finish. The next coat is just plain Matt White and takes a top coat of rattle can nicely too. Did this on my first boat build, Goblin, which now just needs the name and emblem stencilled on.

So first coat of anti-foul is on and rubbed down, need a warmer day in the workshop to have another go.

9 March 2016 at 18:33 #63822Steve Walker 1

Participant@stevewalker1Here are some pics of my first triton. I have had great fun building this little boat. Three part sheets of balsa, a tube of glue, and brass tube and rod and here we are. My complete tool kit is in one of the pics. Found the wife's emery boards very useful! Waiting for some eeze-cote and fabric to hopefully harden the very soft and thin hull. My soldering left a bit to be desired on the prop so I have decided to try a balsa rudder, since this is just a toy after all. Might even buy some proper modelling tools, well a knife anyway.

I am looking forward to doing another when the granddaughter gets here. Thanks for the advice chaps.

11 March 2016 at 19:28 #63854Andy C

Participant@andyc56856Looking very neat and tidy. Much more so than mine.

Andy

15 March 2016 at 16:47 #63894Steve Walker 1

Participant@stevewalker1I have now received by ezekote and given the hull one layer. It has certainly firmed up what was a very soft 1.5mm skin. Glad I did it but also glad I built this trial model first as it is surprisingly easy to try to do too much at once which results in lots of extra sanding on what is after all quite a fragile boat. Never mind, I think it looks quite good and am now off to look for paint.

As an aside, it was £15 for what was quite a small parcel to the island, so it's quite important to me to be able to source as much as I can from one place. I have found lots of bits and pieces at different outlets at cheap prices but once I add on delivery it's amazing what it costs. Happy days….

Regards Steve

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Code of conduct | Forum Help/FAQs

Latest Replies

-

- Topic

- Voices

- Posts

- Last Post

-

-

superglue allergy

Started by:

Alasdair Allan

in: All things floating

Alasdair Allan

in: All things floating

- 5

- 12

-

15 hours, 36 minutes ago

Tim Cooper

-

Building a hull.

Started by:

mick east

in: Scratch build

mick east

in: Scratch build

- 7

- 14

-

21 hours, 52 minutes ago

mick east

mick east

-

Model Yacht Racing – The future ??

Started by:

Ray Wood 3

in: Sailing Models

Ray Wood 3

in: Sailing Models

- 4

- 4

-

1 day, 9 hours ago

Richard Simpson

Richard Simpson

-

Vic Smeed’s Legacy

Started by:

Colin Bishop

in: All things floating

Colin Bishop

in: All things floating

- 6

- 15

-

1 day, 13 hours ago

Colin Bishop

Colin Bishop

-

Eezebilt RAF Fire Boat

Started by:

Tim Cooper in: Build Blogs

- 4

- 9

-

1 day, 14 hours ago

Colin Bishop

Colin Bishop

-

Feathered Friends

Started by:

Chris Fellows

in: Soapbox

Chris Fellows

in: Soapbox

- 3

- 9

-

2 days, 9 hours ago

Richard Simpson

Richard Simpson

-

Vic Smeed’s Silver Mist

1

2

…

32

33

Started by:

Bob Abell 2 in: Scratch build

- 4

- 823

-

2 days, 14 hours ago

Colin Bishop

Colin Bishop

-

4D Modelshop

Started by:

Keith Long in: Scratch build

- 6

- 9

-

3 days, 16 hours ago

Colin Bishop

Colin Bishop

-

Fairey Huntsman 31

1

2

…

5

6

Started by:

Chris Fellows

in: Build Blogs

Chris Fellows

in: Build Blogs

- 14

- 139

-

4 days, 13 hours ago

Chris Fellows

Chris Fellows

-

Fairey Faun

1

2

3

Started by:

Chris Fellows

in: Build Blogs

Chris Fellows

in: Build Blogs

- 7

- 58

-

4 days, 14 hours ago

Chris Fellows

Chris Fellows

-

Fairey Huntsman 28

1

2

…

7

8

Started by:

Chris Fellows

in: Build Blogs

Chris Fellows

in: Build Blogs

- 1

- 195

-

4 days, 16 hours ago

Chris Fellows

Chris Fellows

-

John Cobb’s Crusader

1

2

…

7

8

Started by:

Paul T

in: Scratch build

Paul T

in: Scratch build

- 1

- 192

-

5 days, 16 hours ago

John W E

John W E

-

Complex Automata

Started by:

Colin Bishop

in: Soapbox

Colin Bishop

in: Soapbox

- 1

- 1

-

6 days, 18 hours ago

Colin Bishop

Colin Bishop

-

RAF Fireboat ID

Started by:

Dave Reed

in: Collectors’ corner

Dave Reed

in: Collectors’ corner

- 8

- 24

-

1 week ago

Tim Cooper

-

TID steam tug 42″ – PN Thomas drawing enlarged

1

2

Started by:

Ray Wood 3

in: Scratch build

Ray Wood 3

in: Scratch build

- 8

- 33

-

1 week, 1 day ago

Richard Simpson

Richard Simpson

-

Lady of Skye (puffer)

1

2

Started by:

mick east

in: Build Blogs

mick east

in: Build Blogs

- 9

- 43

-

1 week, 1 day ago

Richard Simpson

Richard Simpson

-

Todays Boating

1

2

…

210

211

Started by:

ashley needham

in: All things floating

ashley needham

in: All things floating

- 84

- 5,252

-

1 week, 4 days ago

Colin Bishop

Colin Bishop

-

Sea Rover Restoration

Started by:

harry smith 1 in: Collectors’ corner

- 4

- 10

-

1 week, 4 days ago

Richard Simpson

Richard Simpson

-

WORKSHOP LIGHTING

Started by:

John W E

in: All things floating

John W E

in: All things floating

- 9

- 18

-

1 week, 5 days ago

Colin Bishop

Colin Bishop

-

Mayhem Website Down

Started by:

Colin Bishop

in: All things floating

Colin Bishop

in: All things floating

- 4

- 10

-

2 weeks, 1 day ago

Colin Bishop

Colin Bishop

-

MAGGIE M trawler

Started by:

sammyk

in: Buy/Sell or Trade

sammyk

in: Buy/Sell or Trade

- 2

- 3

-

2 weeks, 1 day ago

sammyk

sammyk

-

meter

Started by:

Alasdair Allan

in: All things floating

Alasdair Allan

in: All things floating

- 5

- 16

-

2 weeks, 3 days ago

Chris Fellows

Chris Fellows

-

River Queen 2”- 1’.

Started by:

Richard B in: Steam powered models

- 5

- 7

-

2 weeks, 4 days ago

Richard B

-

Deluxe Superphatic Glue.

Started by:

Colin Bishop

in: All things floating

Colin Bishop

in: All things floating

- 4

- 12

-

2 weeks, 4 days ago

Chris Fellows

Chris Fellows

-

How to add photos to your posts

Started by:

Colin Bishop

in: Adding Images to Forum Posts

Colin Bishop

in: Adding Images to Forum Posts

- 3

- 16

-

2 weeks, 5 days ago

Len Morris 2

-

superglue allergy

-