Happy new year all!

Thanks for your comments Bob,you are a gentleman, for sure!

As requested.

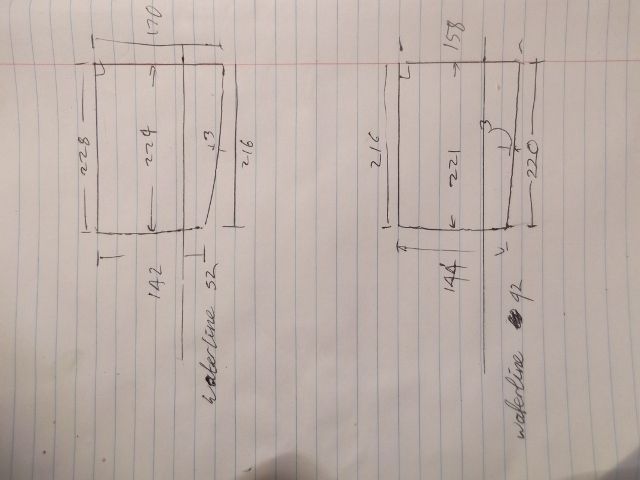

Engine is aprox. 13" wide x 10" long x 8" high, weight 10 lb.

Ashley

A mild steel prop makes good sense to me, cut and twist until about right, then replicate.

The engine is mounted as low as we can get it, given shaft angle, exhaust and carburettor position.

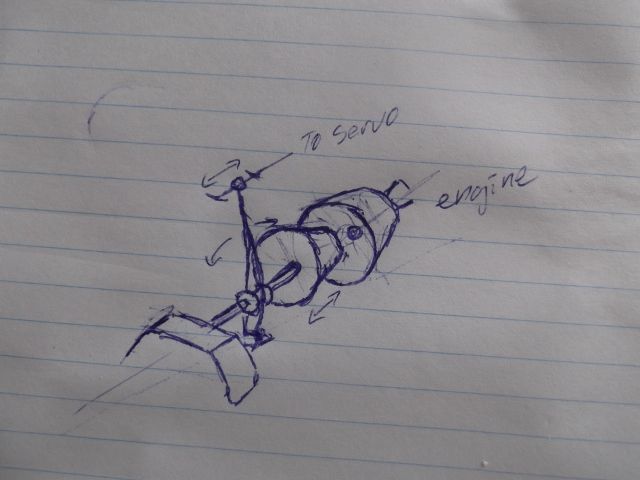

Some explanation regarding coupling;

We are planning on using an old fashioned cone clutch, as both clutch and coupling, which will be engaged by sliding the entire prop shaft fore and aft. Of course the amount of actual travel will be small, Lynn thinks perhaps 1/8" will do. A simple lever engageing a collet on the prop shaft and actuated by a servo, should work. With the motor idling at about 1200 or a little more, boat speed will still be considerable. Clutch parts will be turned from a softish plastic, (my old skate board wheels perhaps?) prop thrust will keep the clutch engaged. There is a prop tube, but the shaft will be running in the wooden bearings, the lower water lubricated, the upper will have a oil cup. I think the engine will need to be fairly firmly mounted.

Thoughts anyone?

The tank will be separate, gravity feed, (The carb is mounted low)

more photos of progress thus far.

engine mounting frames cut from 1/2" 5 ply. Slotting into the base makes for strong, accurate construction.

engine in position, (though not installed) The frames are the full width of the boat, 18" beam.

Thanks again

Aj & L

.jpg)