Kim. We are not quite at the "needing heavy lifting equipment" stage, not just yet anyway. A sling and two people is a much as we have needed so far..but then I am young and viggerus..who knows when I get to Pauls age I may well have to convert everything to pumped water ballast.

I did see a picture of a very neat self contained electric lifting system..cant remember where though now..just a frame that sat over the waters edge and it had a gel battery for power. When the time comes, or I build that bigger model I will have to get the Mig welder out!

I have only actually seen one pumped ballast system at the pond, and this was a very large landing craft. It needed, as you can imagine, a lot of water to be pumped inboard and the little "fire hose" type pump took ages, and we were all for holding it under, it was so slow.

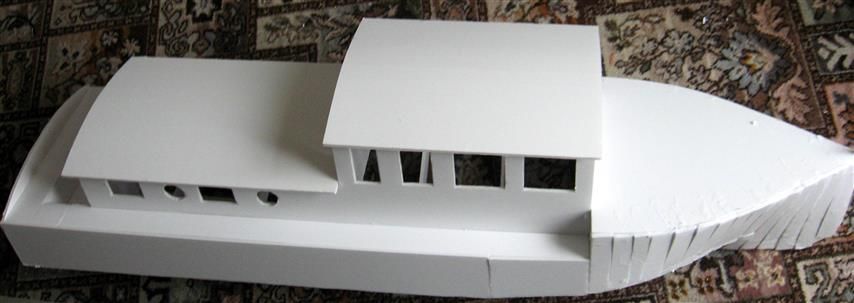

I think that discussion of launching and recovery is quite valid for any build, especially one using unusual materials, such as foam reinforced card. It is no good building something if it sags when lifted or is too heavy/delicate/wide/whatever to launch.

I had been looking forward to a bit of boating action tomorrow… but as I am typing this, the sky has gone a really really really dark grey…. doesnt bode well for tomorrow!

Ashley