Hi Bob,

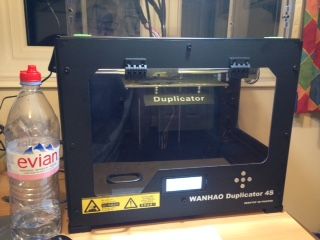

The 3D printer is a WANHAO Duplicator 4S (The dual nozzle model). Therefore meaning i can print in 2 of the 3 possible plastics at any one time. This dual nozzle type of printer allows me to print what i think you are talking about with the image above, complex innards.

Although, that laser cannon type thing was made completely with the 3D printer; it is for show so has not actual innards such as piping or channels that you would use to fire projectiles/water. However, i can print absolutely anything, joints, gears, propellers ect and blocks/objects of material with complex pipe work in build.

The way in which i do this is use either PLA or PVC (the 2 none water soluble plastics) to print the main object with then PVA (the water soluble plastic) in all the places you don't want there to be any plastic at the end.

The reason one must do this is because the PVC or PLA cannot be printed into thin air so requires the PVA as a support structure (serving a purpose kind of like scaffold in real buildings) so once the item is constructed up in layers with all gaps filled with one of the 2 plastics it is then submerged in water. Resulting in the PVA dissolving leaving your complex item ready to bolt straight onto your boat!

If you have any other questions on the subject i might open a separate thread about it and would be very happy to answer them.

Matthew

Edited By Matthew B on 26/01/2015 17:01:53

Any help would be most appreciated

Any help would be most appreciated