Dave/ Paul,

I didn't ask for your advice and intentionally ignore it. I was simply drawn in by my pile of spare plywood that I had.

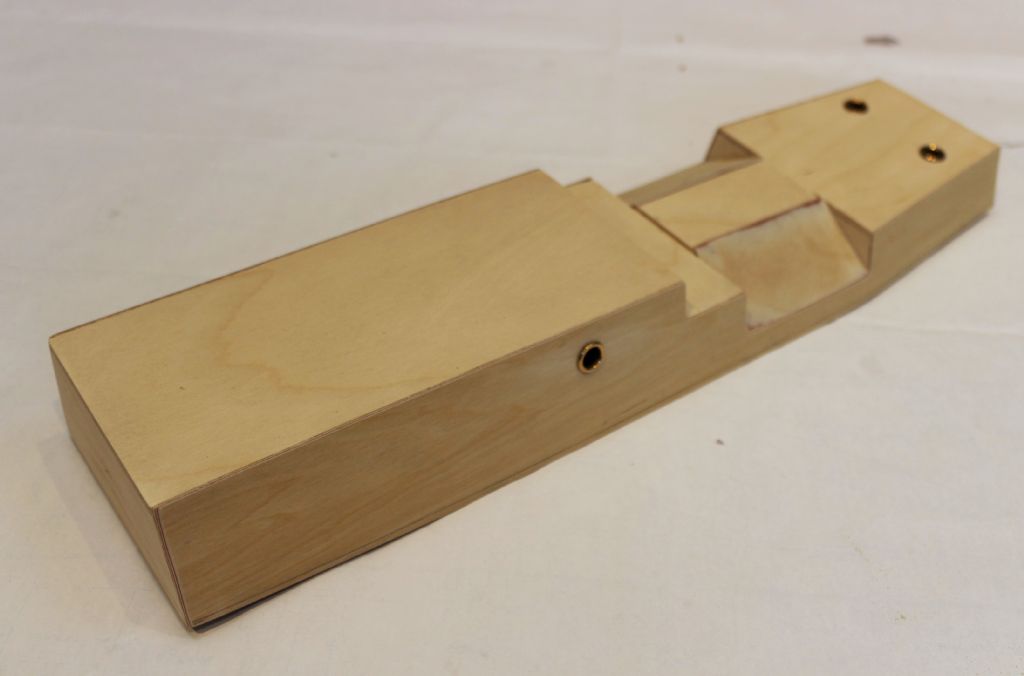

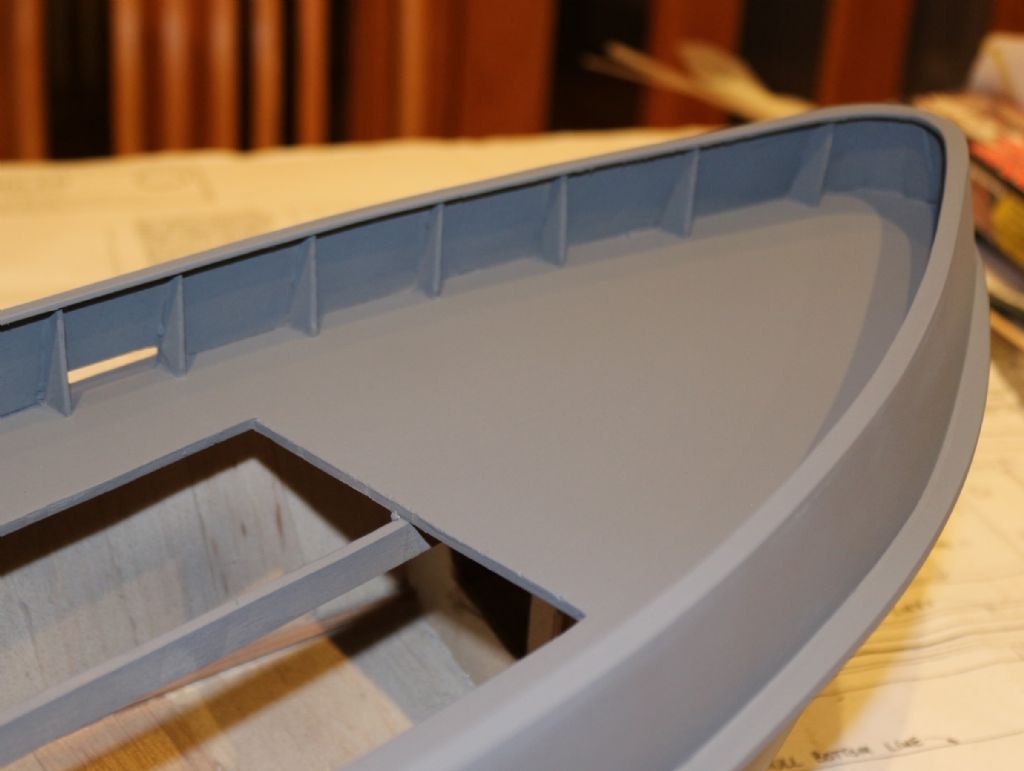

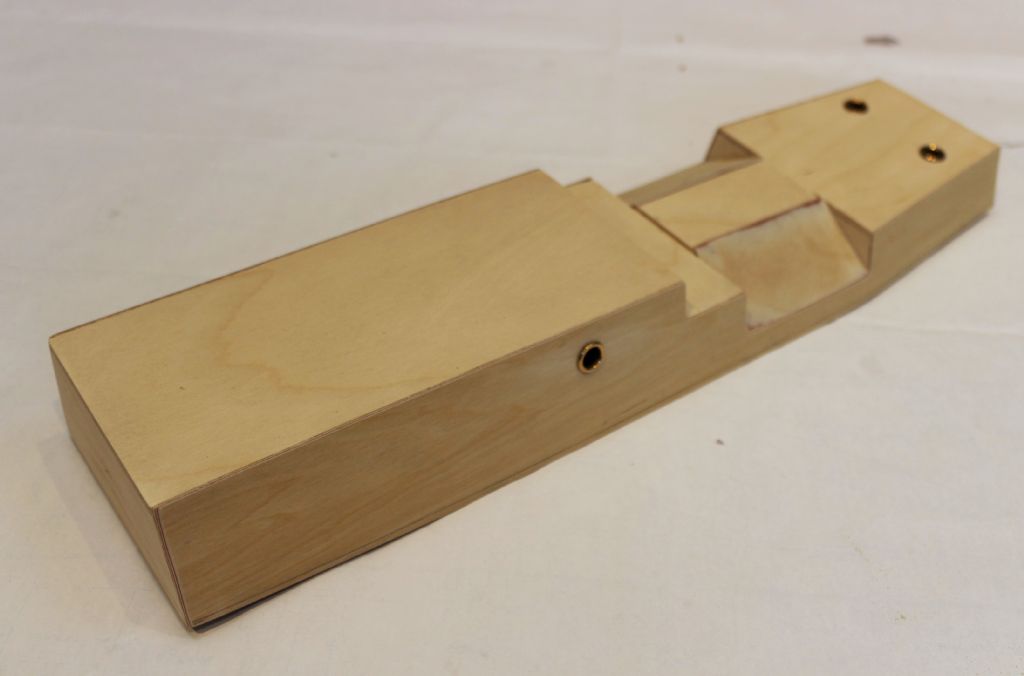

For the main superstructure, I used 1/8" plywood frames and top with strip wood spacers/ supports for the1/32" thick plywood sides.

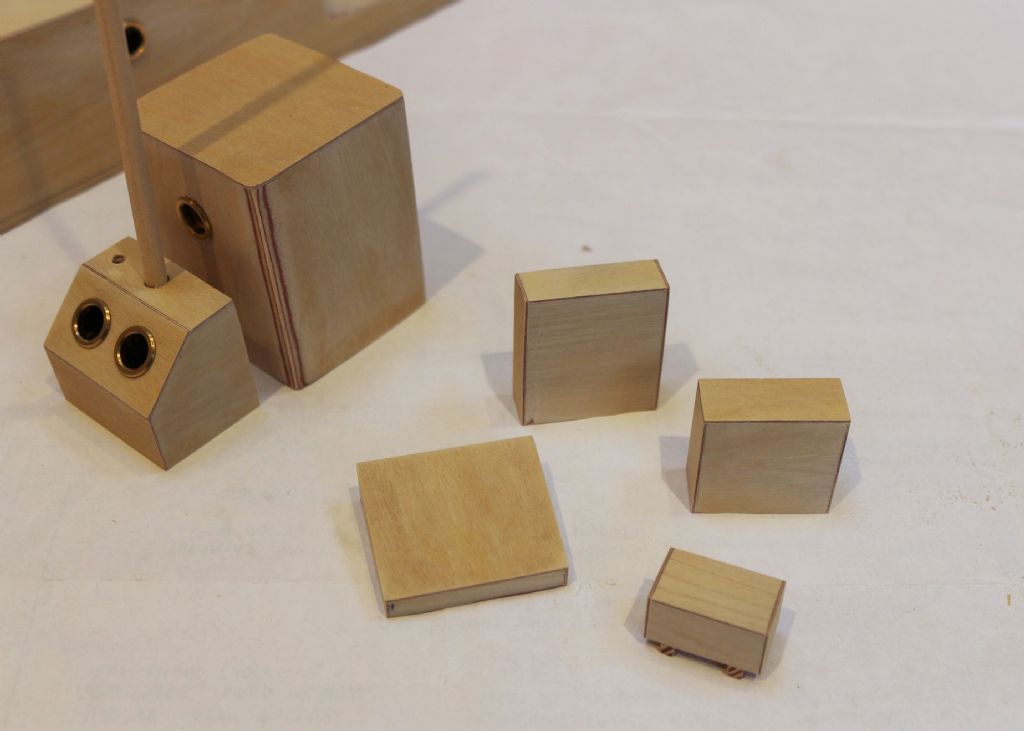

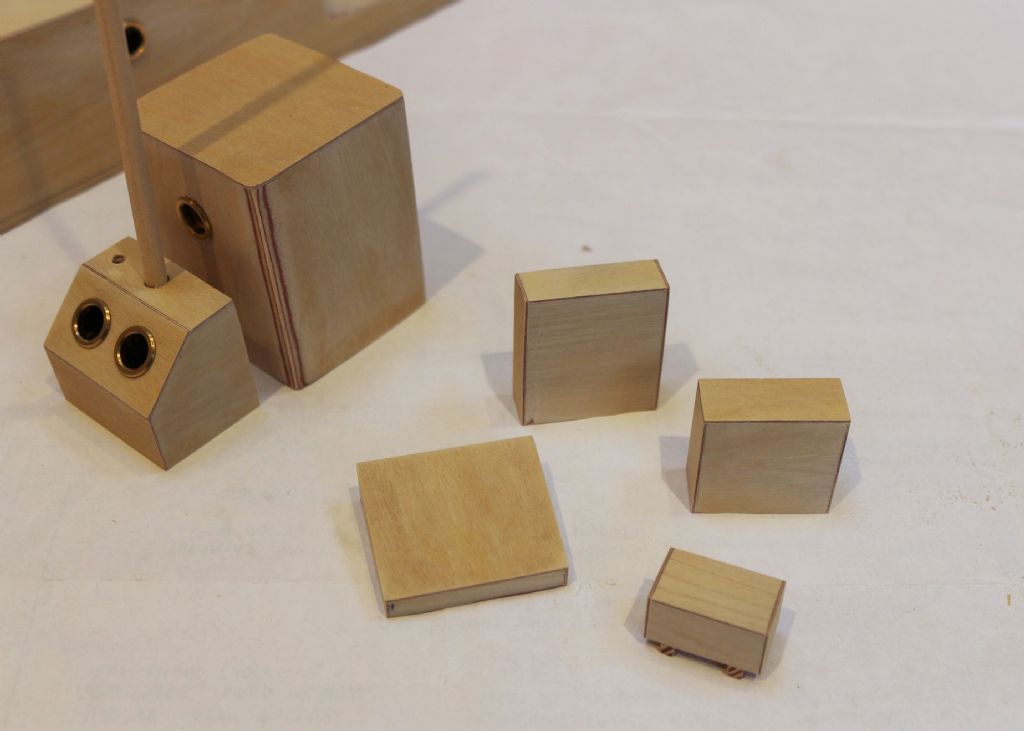

I built the accommodation and various tank type features by gluing together bits of balsa to form a block. The balsa block was then clad with 1/32" ply and sanded smooth.

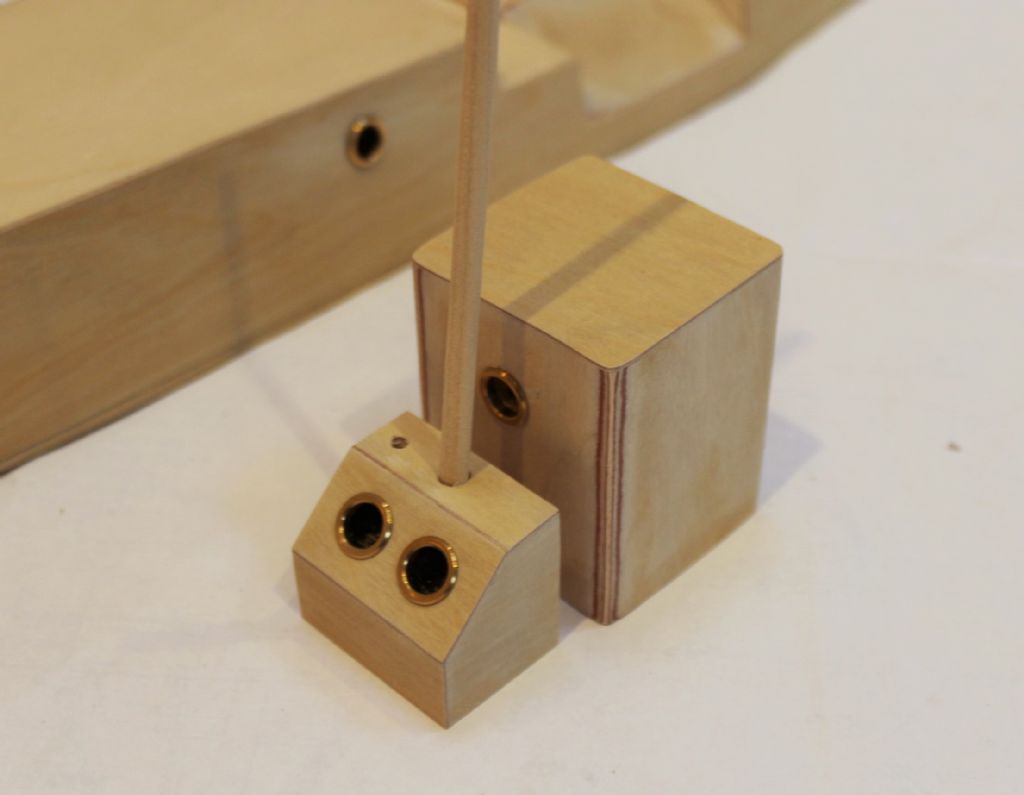

Cutting out the wheelhouse window frames were a bit tricky but I think they look ok.

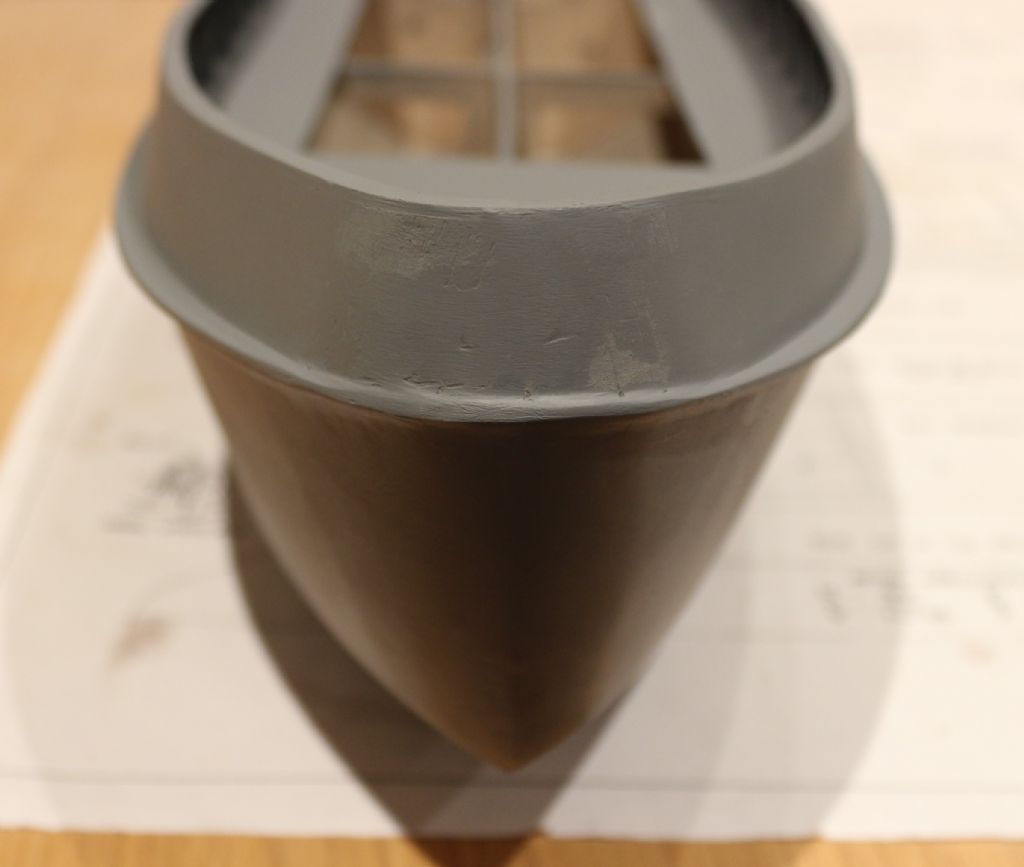

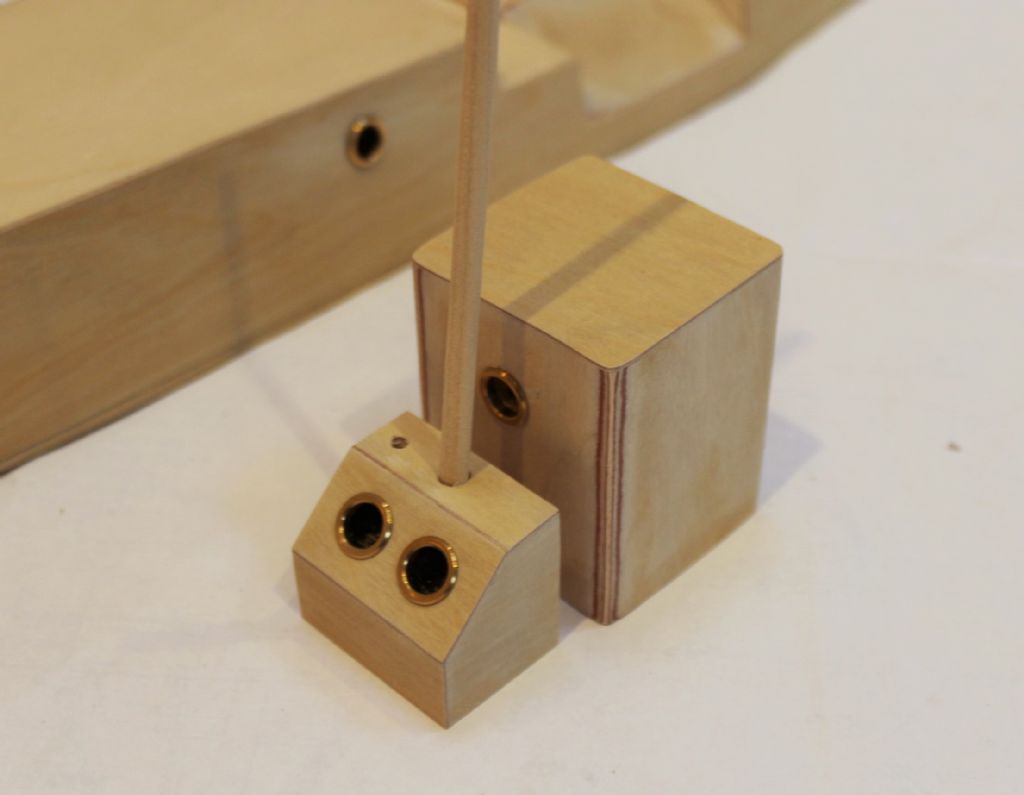

Now for the confessions…… yes I know I should have turned them myself but the pack of bright shiny brass portholes hanging in the model shop were too tempting. I guess I should also come clean about the plastic swan neck and cowl vents that I bought…. sorry.

Anyway, I drilled all the holes for the portholes in accordance with the drawing but there appears to be an error. The porthole in the accommodation is on the centreline immediately behind the mast. Its either an error or quite dark inside the accommodation so Ill fill and move it.