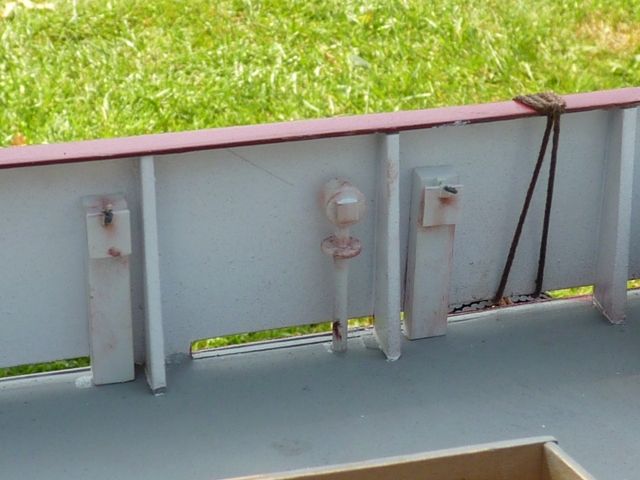

Hi Shemarah fans one and all, sorry to disappoint you but I did not take any photos of her in action last weekend at Goole. Quite a lot of time was taken up supervising our Springer have a go boats which were particularly popular in the good weather. However I did get one photo of Shemarah tied up in harbour. Since its so heavy it was easier to leave it on the pond all day rather than move it backwards and forwards from the table in the GMBC gazebo.

I like the look of your rust Larry, very impressive. I see that it is now possible to buy some weathering powders for applying to models so I am going to try and get hold of some at the CADMA show this weekend. I dont think I will be making Shemarah look too old and uncared for, just nicely weathered.

I dont think Shemarah will be making the trip to Llandudno. Since its primarily a Vintage Model Yacht Group event I think we will have a car full of them. At the moment Elizabeth is planning to bring her two vintage Marbleheads (one for vane sailing) and her newly completed 36R Razorbill. We will probably bring a Springer rescue boat which might just leave room for our narrow boat. We have recently been looking at vehicles to replace our Honda CRV and model boat transportation is a key performance factor. The most critical requirements are having a flat floor with the rear seats folded down and space to fit a 78 inch long sailbox, which goes up in the roof in the CRV, suspended from bungees across the grap handles. The best option so far seems to be a Toyota Verso.

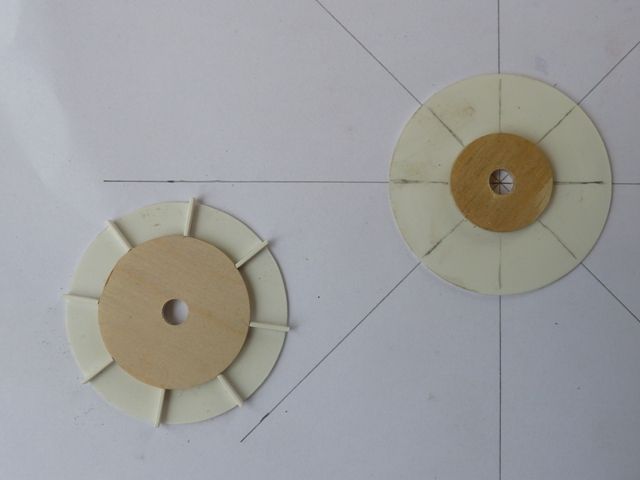

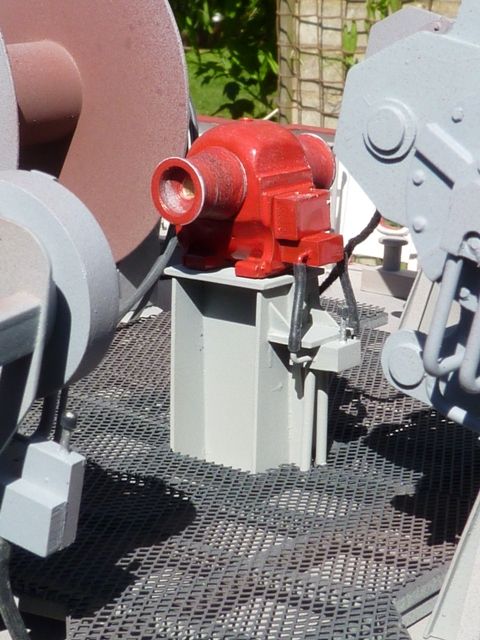

This week I have been making the warp head winch for Shemarah. The warping drums were made from two styrene discs mounted on a short length of 4 mm styrene tube. The discs are cut from 1 mm sheet using a suitably sized length of brass tube with a chamfer filed on one end to make a cutting edge. I have tried stamping them out using these tubes but I find its better to cut them by mounting the tube in the pillar drill and cutting down through the styrene on to a wooden block. The discs were then glued to the tube and the space between filled with P38. When this had set, a short length of brass rod was pushed into the tube, making a reasonably tight fit, so that the drum could then be sanded to the right shape in the pillar drill. Heres the finished example with both warping drums back to back on the brass rod which locates them in the winch.

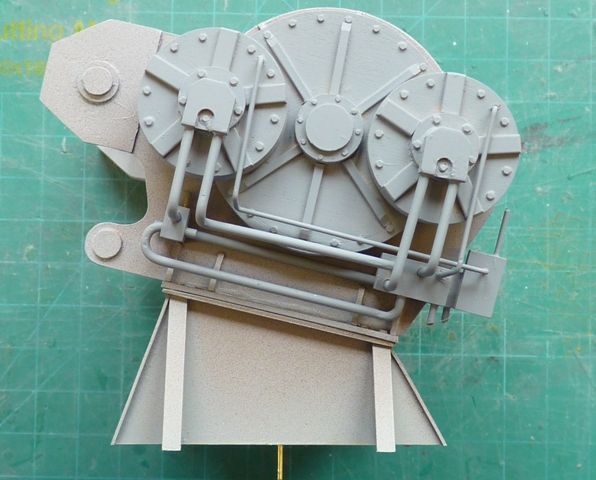

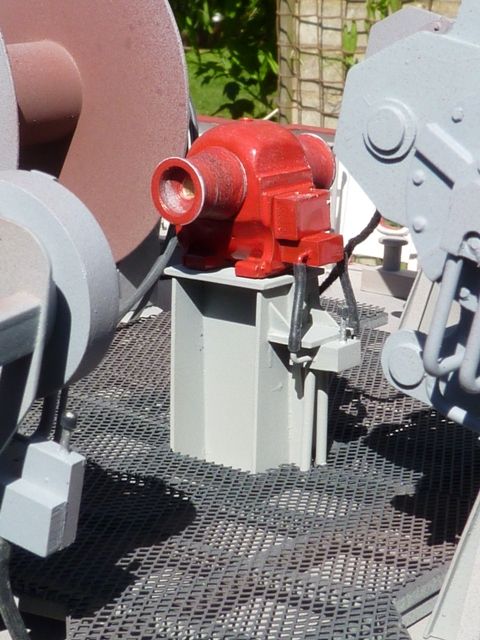

The winch platform was built up from styrene sheet and locates in the deck using my traditional brass pins. The body of the winch was built up from a short pieces of wooden dowel, a short length of aluminium tube and assorted styrene bits and filler. A few photo etched brass nuts add to the effect.

The hydraulic control valves were added before painting. I do not have a good photo of the front face of the full sized assembly but the final version is quite realistic, if not completely representative.

.

.

The next step is to move back to the front, so to speak, and I plan to make the deck pulleys for the A frame hoist, followed by the winch and rigging blocks for the derrick. This weekend we will be at the CADMA show in Doncaster so if you want a closer look, come and see Shemarah on the Goole MBC stand.

Gareth

Edited By Gareth Jones on 08/06/2013 07:50:44

Edited By Gareth Jones on 08/06/2013 07:52:27