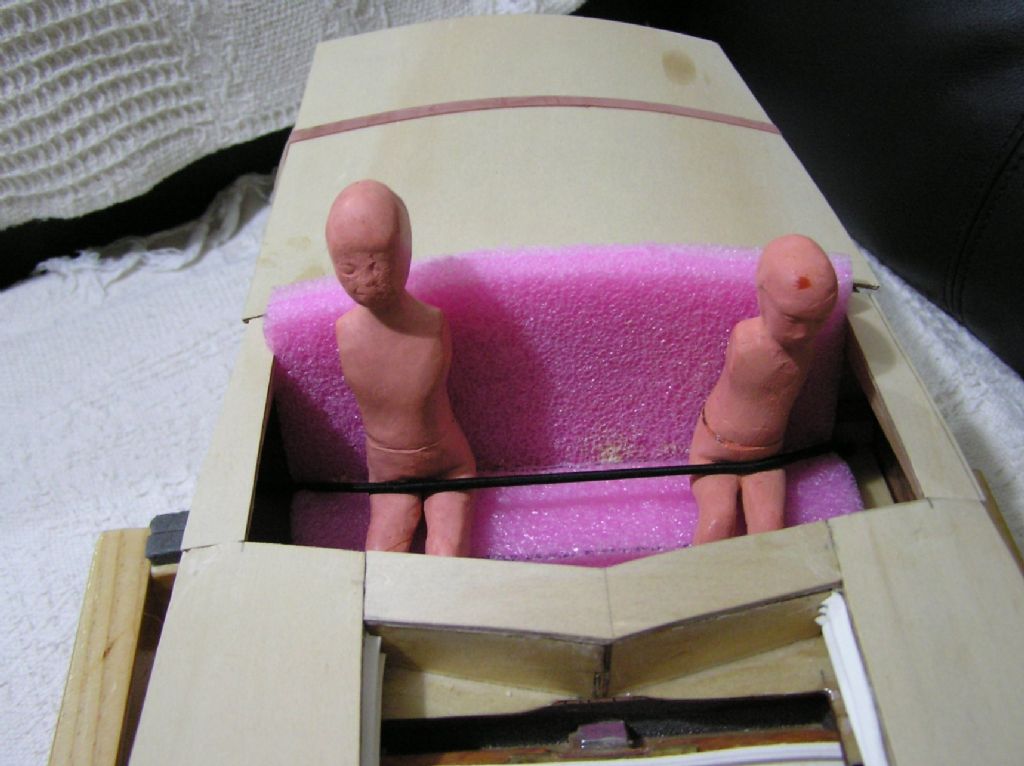

Hi Colin and Ashley

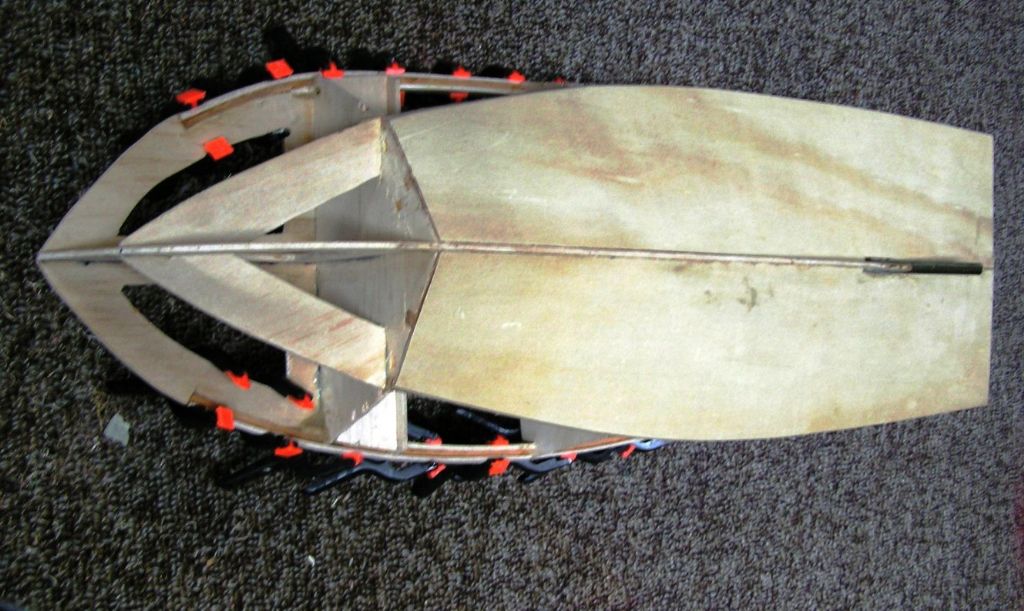

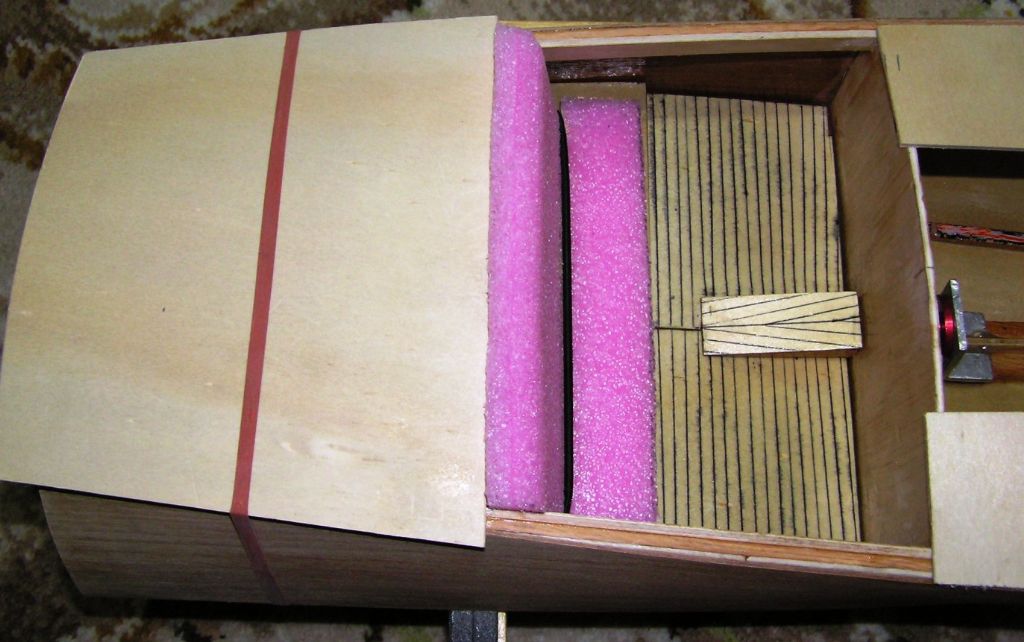

The sides are 40 year old 1.5mm marine mahogany three plywood(no longer available), but its water stained.

So I tried to clean it up but no luck.

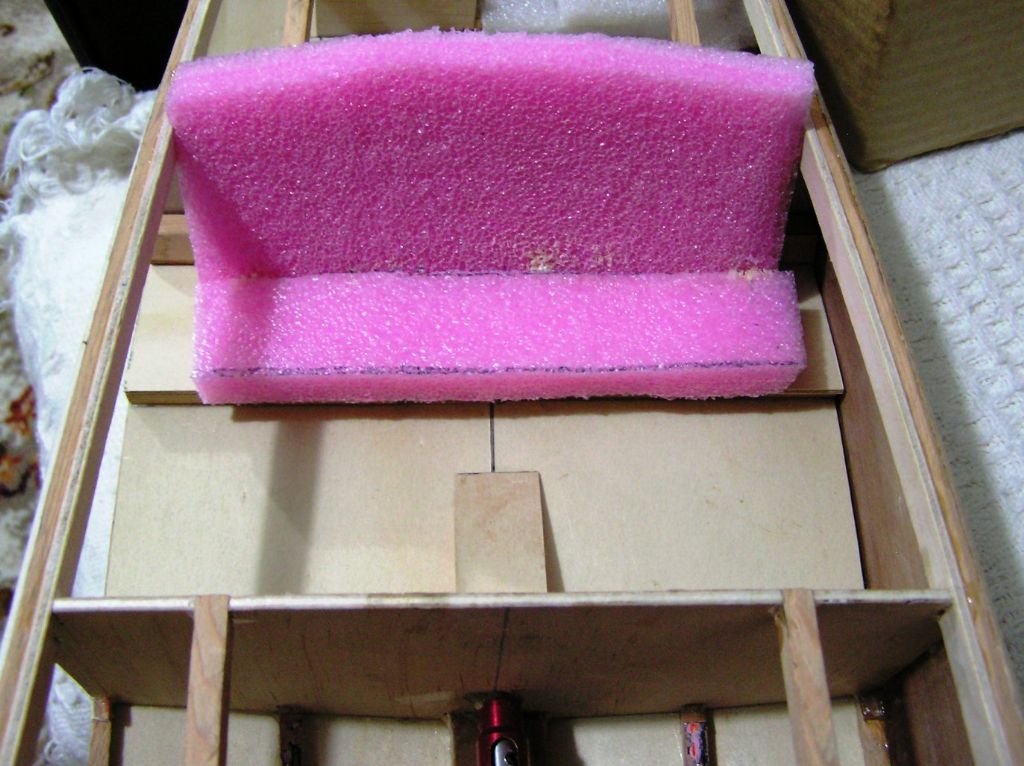

So I tested a piece with fibreglass resin plied with a piece of hard packing foam, it did not leave brush marks.

I gave it a quick sand with 120 grit, nice and smooth.

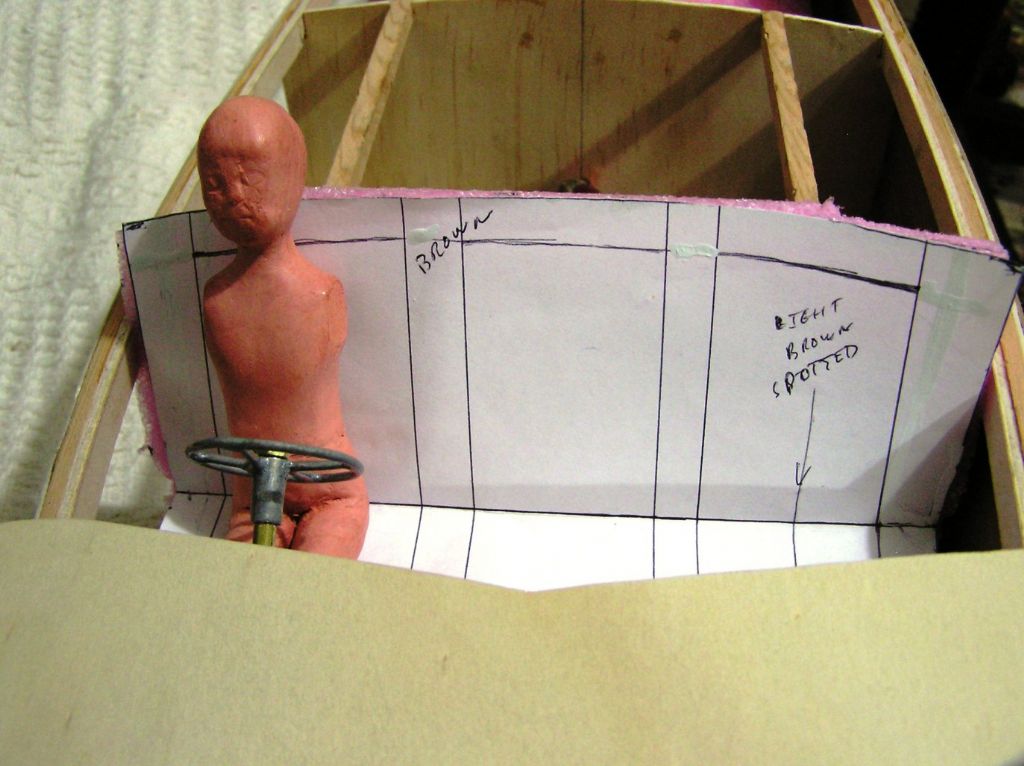

So I think of painting the sides maroon with a gold strip?

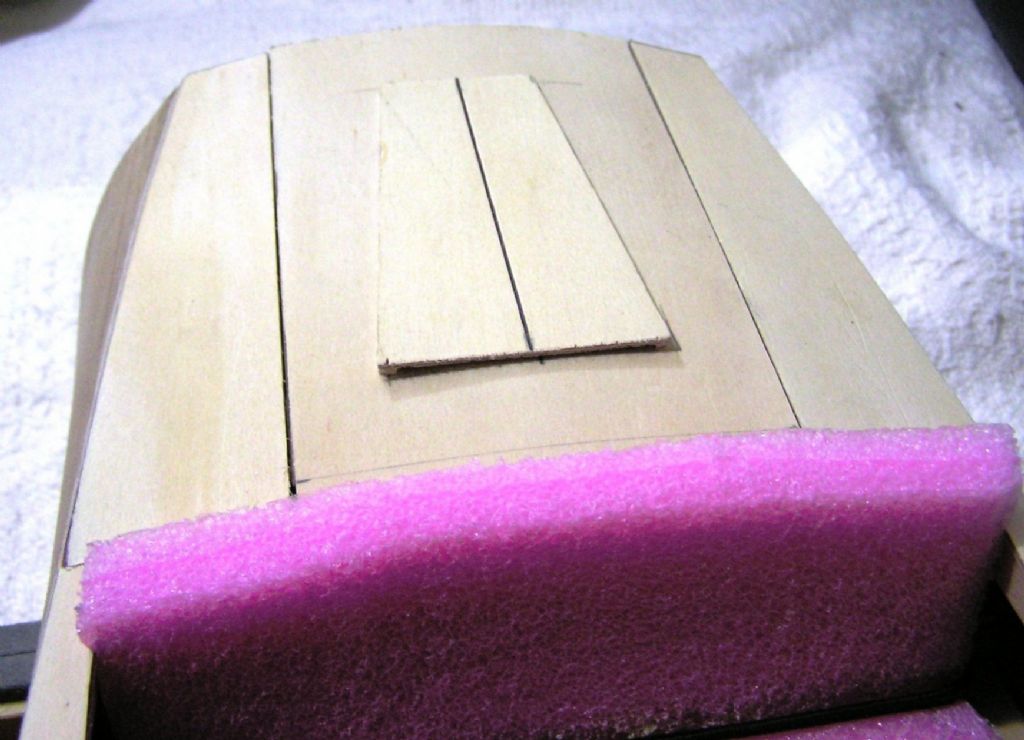

The top is to be planked(dark and light Tasmania timber).

What did you think of the rudder a fellow member made for me???

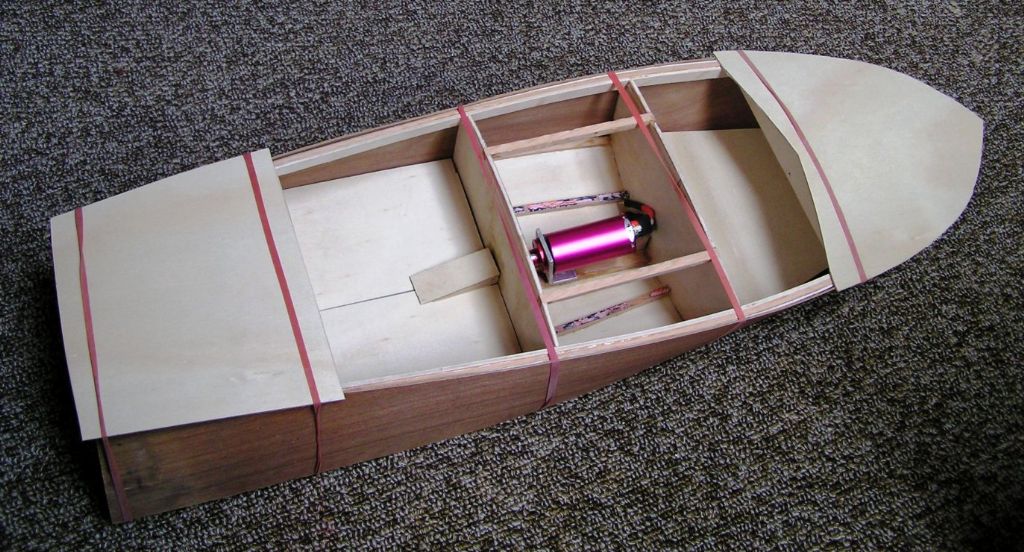

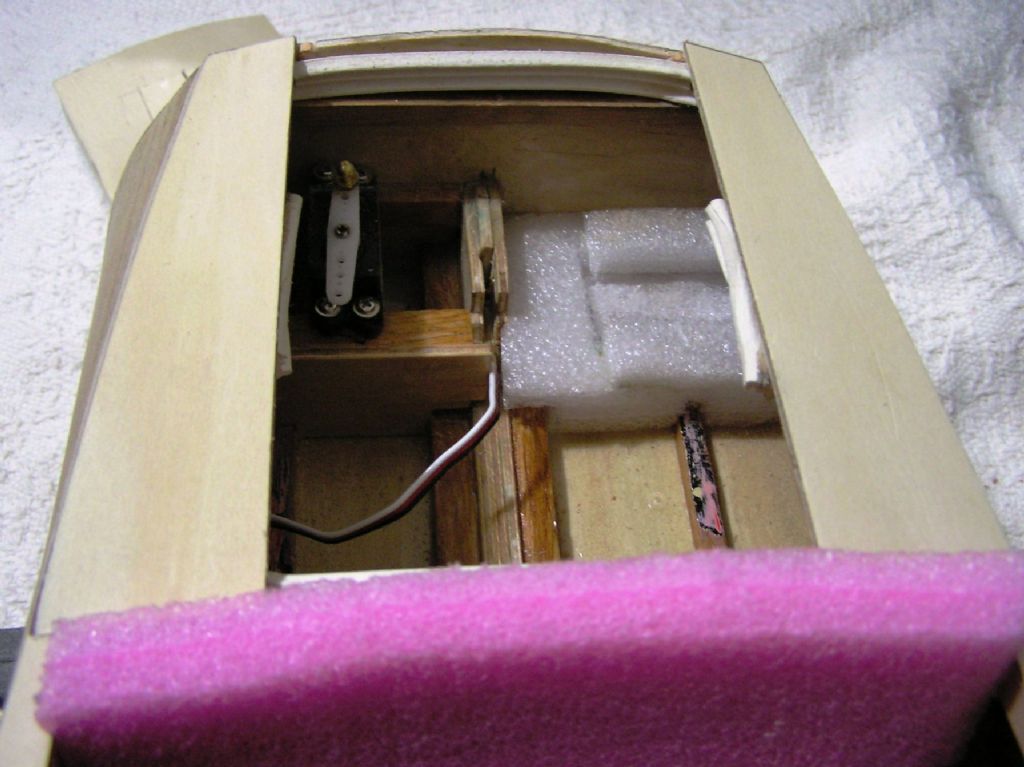

Battery 3S 2650mah 30C or 4S 2650mah 40C.

ESC car 45A or 60A (heap of room in the engine bay)

Motor I have a XK2845B-2000kv(280watts), a B28-57-15L 1900kv(750 watts)(THE LONG THIN ONE)and 2836-3700kv(700watts).

I also have a 3000kv motor on my Hobbyking outboard(it's on my 24" deep vee).

Prop 2 blade alloy32mm x 1.4 pitch(spare for the outboard) or the 30mm x 1.4 pitch 3 blade plastic which is in the Hobbyking BP22-S PROP kit.

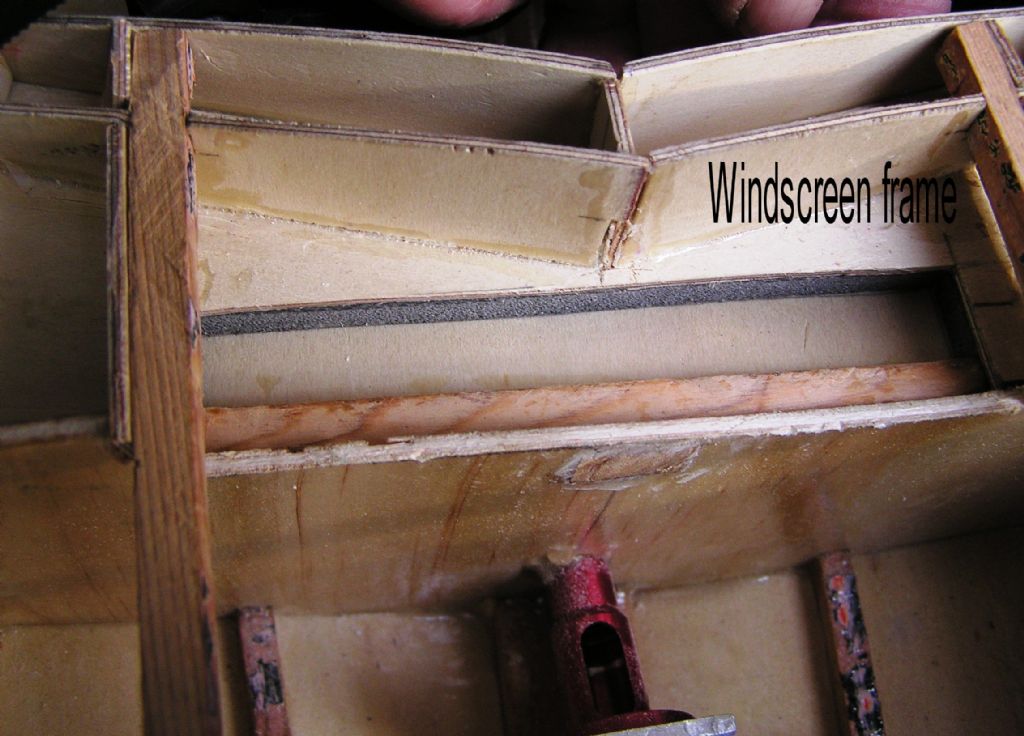

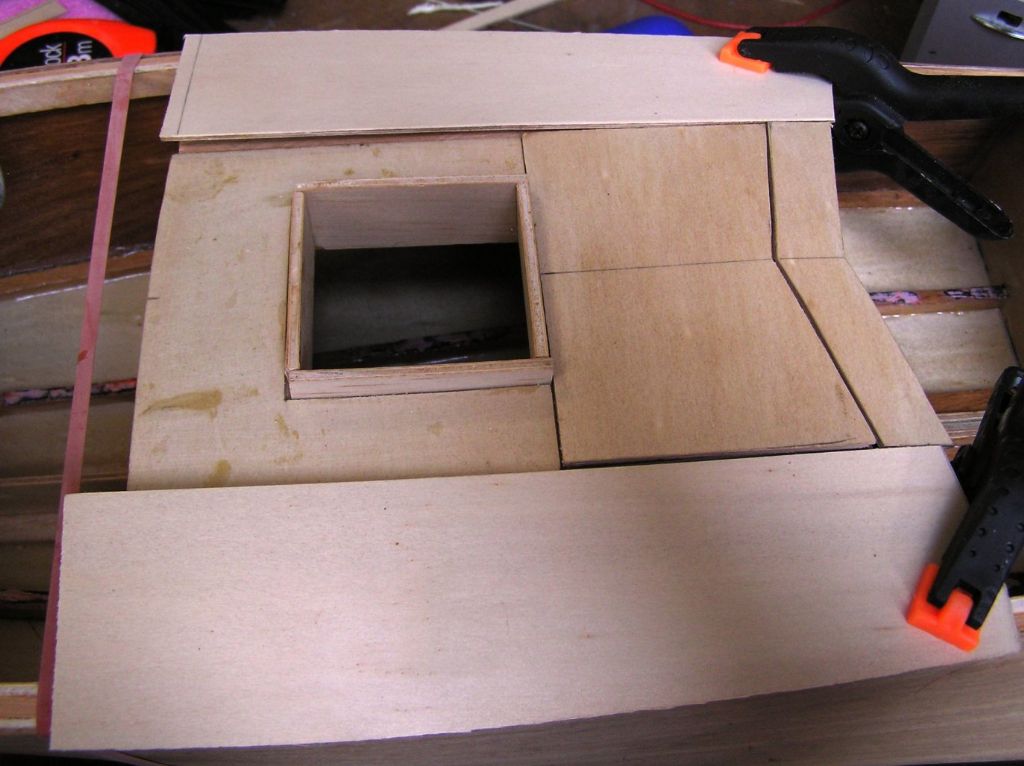

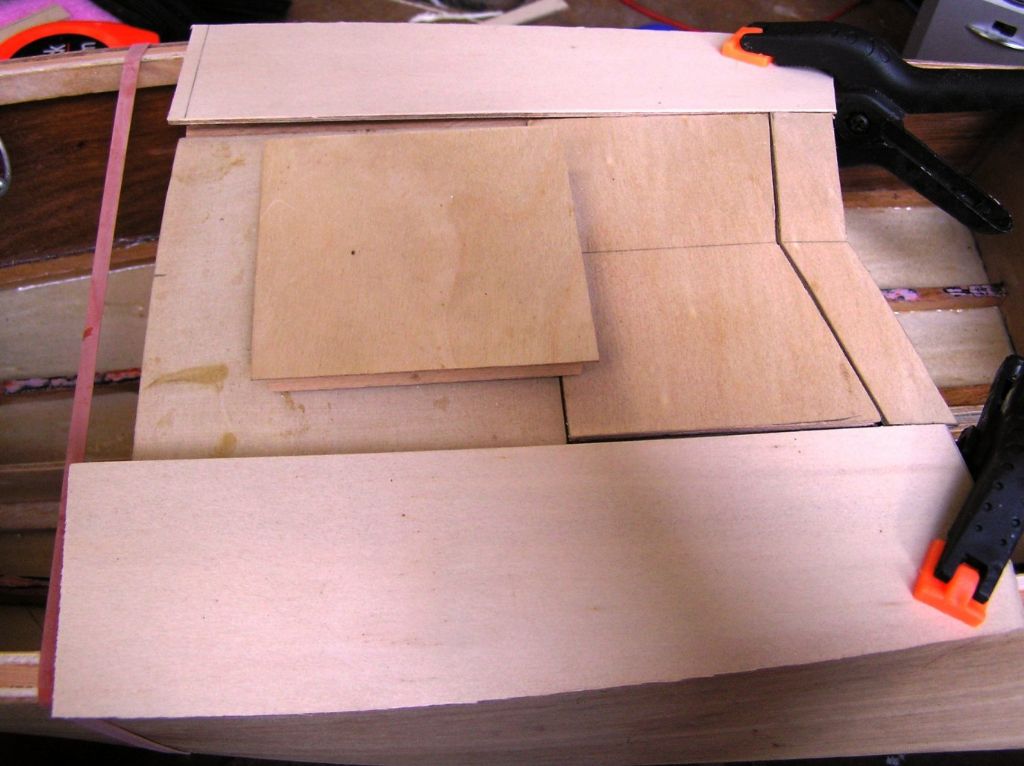

I am planning to change the engine cover setup and make it 100mm wide with a small hatch on top.

Extending the open section back to the rear wind screen so the planking looks better.

This will let me add an opening under the rear closed in dash for an air vent into the engine bay.

Also adding a closing door with seal and a weight, so if the boat ends upside down the door will shut the water out!!!

I HOPE!!!!!