Hi Dave

As my mentor DM has stated on your other thread getting the propshaft angle as shallow as possible is a little foible of mine and I do get aggravated if my designs exceed a pitch of 4deg.

However 12 degrees is better than 14 and as there are limitations imposed by the 850 motors you wouldn't seem to have much choice.

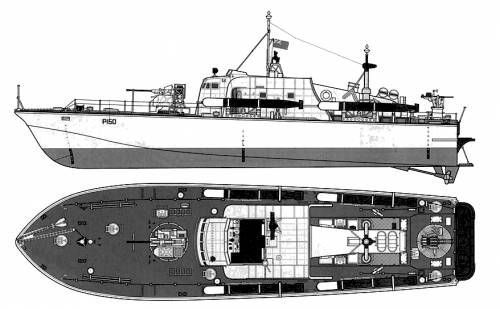

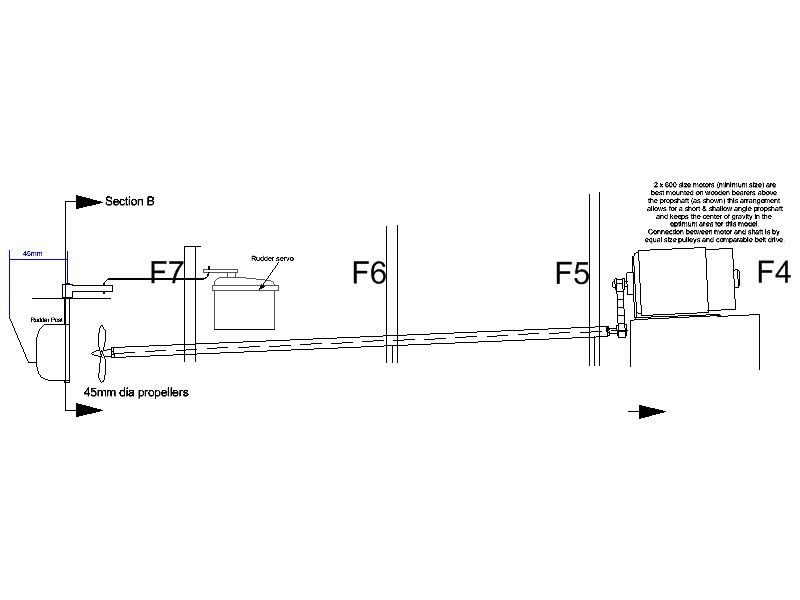

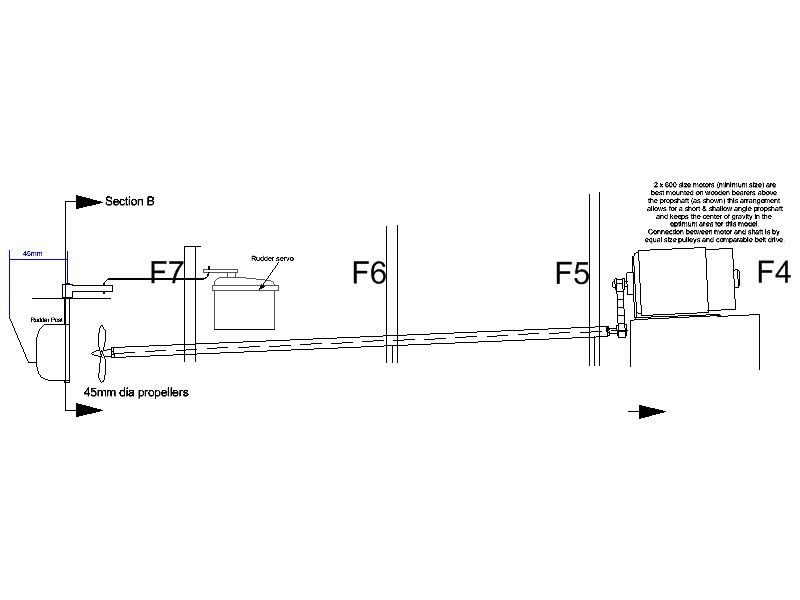

The subject of propshaft angles has been discussed before and as excessive angles are one of my pet hates I offered the following solution for those building my Brutus where I had designed a model with a propshaft angle of 2deg.

Mounting the motor slightly higher and using a belt to connect the motor to the propshaft allows for a shallow angle installation, and the consequent increase in propeller efficiency, whilst not compromising on the choice of wider diameter motors.

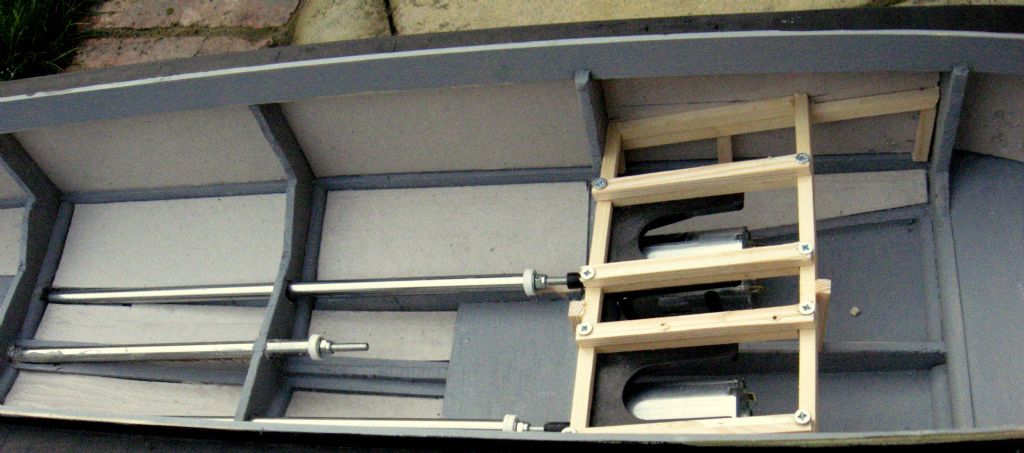

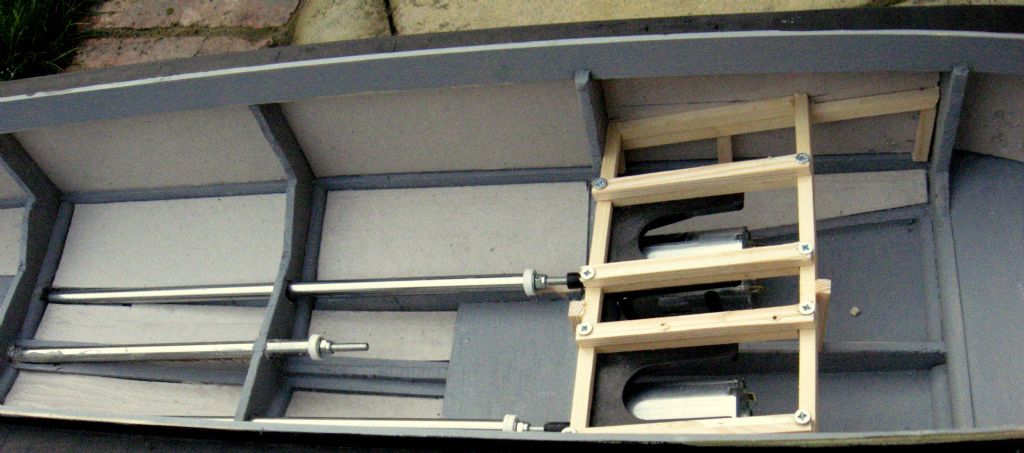

Another way to achieve the same result is to install the motors in an inverted position by hanging them from an overhead frame work.

Here is an example of an inverted motor installation in a triple engine setup in an MTB (centre engine not installed yet)

A closer image of all three motors in position, hanging the motors in this manner allows the motors to be fitted lower in the model with the motor can almost touching the inside of the hull.

A final image showing the shallow angle shafts, props and rudders

Paul

Edited By Paul T on 03/06/2014 13:34:16