Another long overdue update.

I have been working on the cabin deck, sails and painting over the

last few weeks/months.

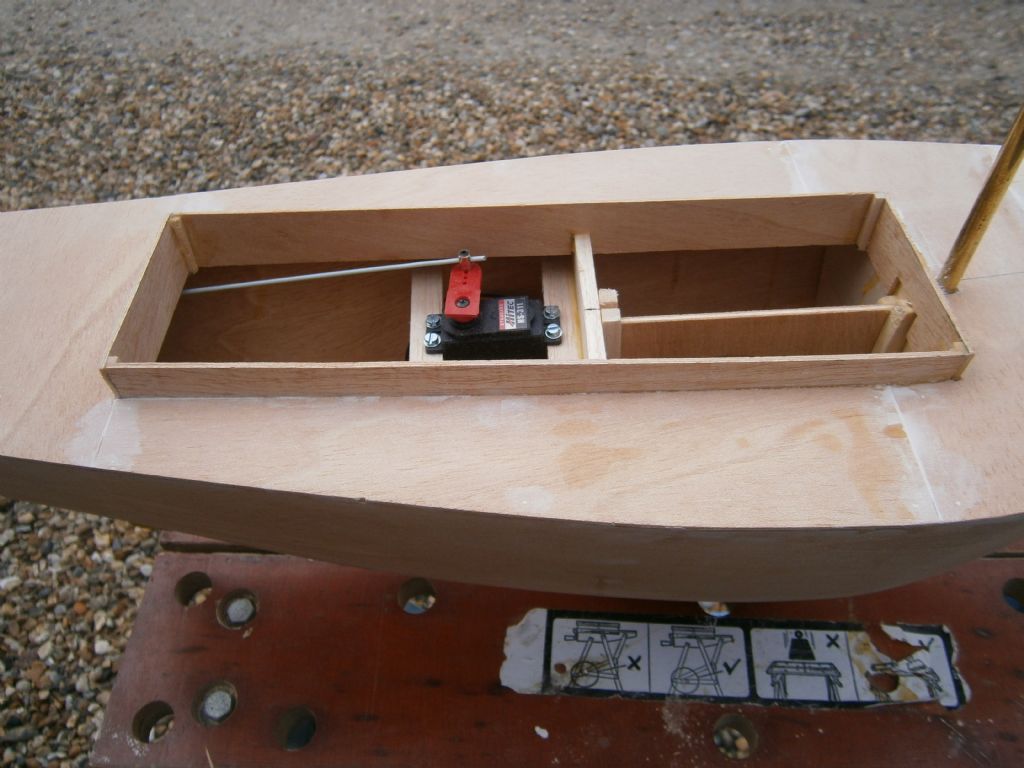

Cabin now completed and fits very well to the deck.

This the cabin fitted and the boat given a coat of Hemple marine underwater under coat.

I choose to use marine paint after reading through a lot of threads on painting and finishing.

If it is good enough for full size boats, should be ok for my little Goblin.

I put two very good coats on and followed it with a coat of Hemple two part gloss white,

this paint can be used as an undercost (odd for gloss, but that is what it says on the tin)

then a top coat can be added.

Then started to work on the sails, following the guide set out by Glynn.

Used an old umbrella to make the sails as it should catch the wind nicely.

Main sail fitted mast.

Not completely happy with the results as the tape looks out of place, so i

tried a different method with the foresail. I made it slightly over-size and used

Wonderweb to make a hem. worked really well and looks good too.

Now to see if the thing actually floats. Filled the bath with a lot of water to get

clearance on the keel, but to my complete amazement it actually does float.

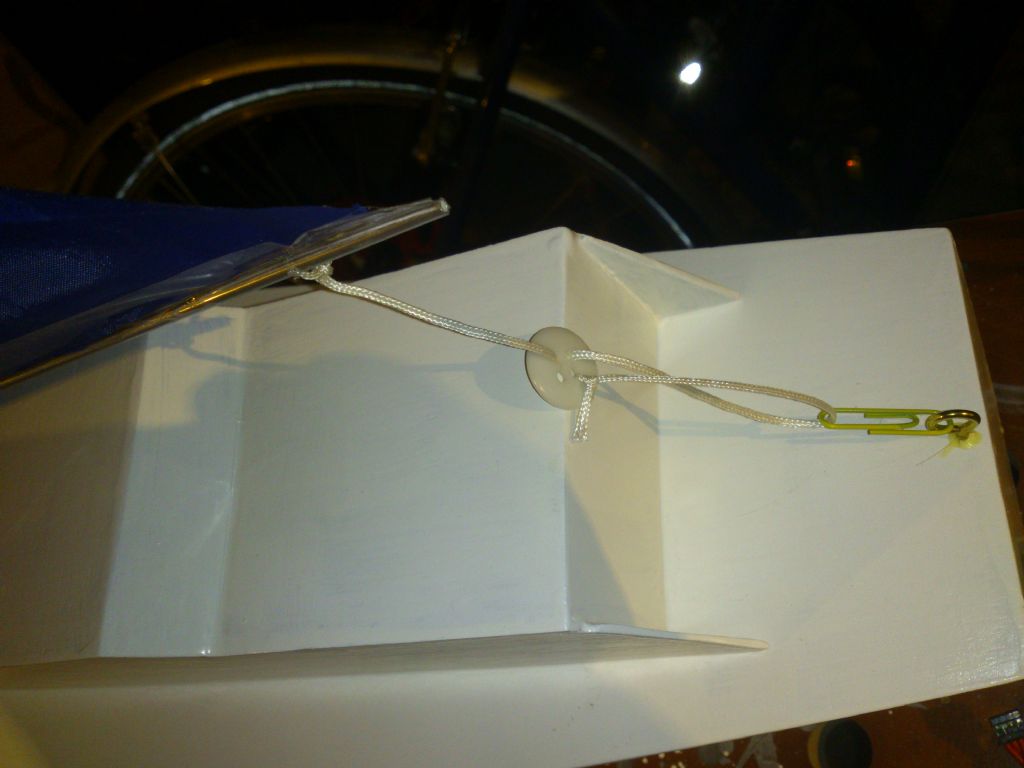

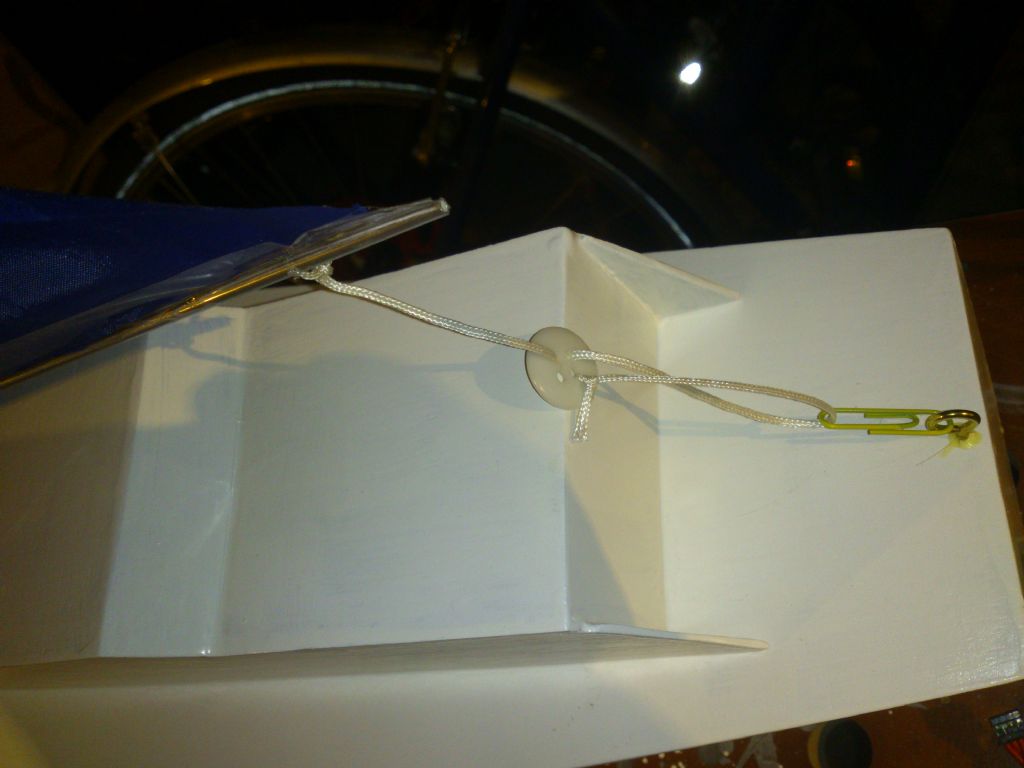

A close up view of the sail adjustment ropes (well string and a button).

Just have to finish painting the blue above the water line and finish the RC install,

but should be able to try her on the lake at Bushey.

More next time.

Regards

Andy

Edited By Wraith Leader on 08/09/2012 09:33:23

Edited By Wraith Leader on 08/09/2012 09:34:19

Edited By Wraith Leader on 08/09/2012 09:34:51

Edited By Wraith Leader on 08/09/2012 09:35:56