Hello Penny

Thanks for the information: I understand the principals involved with the removal of the air from the centre compartment but the storage in the forward compartment has me slightly bemused. I presume that some kind of pressure vessel is employed as the storage pressure is 1 bar, could you please clarify what kind of storage system is used.

A further question would be what about the free air that is in the forward and rear compartments? has this bouyancy any affect the dive or is the flooding of the single compartment sufficient to achieve this?

Hi Ashley

I appreciate and understand your comments on dynamic diving but I am trying to atchieve a dive system that will work in the stationary position.

Hello Mike

Thanks for the message, you must have had a great time working at the sub school.

Paul

Hi Paul

You see what I meant when I replied to Ashley? “You have scored an unintentional bullseye! I may scrub the post and replace with two or three line diagrams…..”

Yes and Yes. You can see that forward and rear compartments are held together by brass tie rods. Central ballast chamber has enough volume to displace considerable superstructure weight. The forward compartment air pressure rises.Pressure rise limited by the servo op. release valve which leaks air if pressure differential exceeds 1 bar.

Forward compartment pressure does not reach a dive pressure of 1 bar and dive pressure can be reduced further to 0.4 bar by removing the FWD-REAR seal so air sucked from middle goes to fwd/rear compartments .You have to get a calculator out (adiabatic pressure equation) because the elevated pressure is reached when you dive to the inversion depth…..if your compartment ratios are such that you get 0.4 bar then you don’t want to release or else water comes in throgh comressor and you sink.

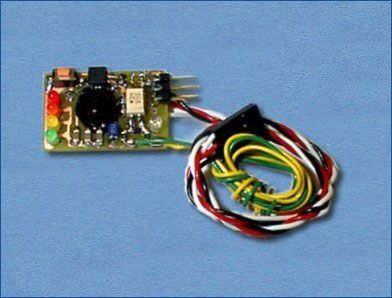

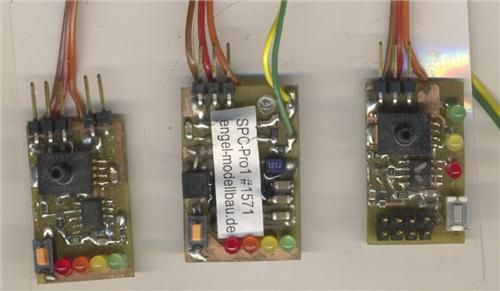

……..That is the achilles heel but fortunately there are all-singing all-dancing failsafes that monitor pressure,voltage,radio,overtilt. ….If you get 4 metres before “dive manager” kicks in then you have drinkable water. The images attached includes a depth control with output for ballast control/dive manager

- Servo depth control (forward planes)

- Engel SPC Pro pitch control (aft planes)

- servo depth control with failsafe outputs

The grey box servo/compressor ballast control was replaced by a “dive manager” for Craycraft system and a digital servo failsafe for bidirectional pump system (works with sheerline/Otw pumps) -………google modelcontrollers + nautilus for those bits but I have instructions here somewhere as well as the AST which was the basis of Engel’s SPC Pro. I attach a picture here.

I fear the above reply will mean much less than diagrams and photos. I’ll try tomorrow eve.

Penny Lee