The parameters I’m working to are 2mm cable diameter, minimum cable bend radius of 20mm and max radius of 35mm (to accommodate the 75mm diameter plus 2x cable radii plus 1.5mm clearance).

DRUM

The volume of the drum of wire is drum length x coil area

V = L x pi x (r2² – r1²

where V = the volume in cubic-mm

pi = 3,14159

r2 = the outer coil diameter in mm

r1 = the inner coil (former) diameter in mm

Cable length, assuming that the cable coils lie next to each other and occupy square secion places, is the volume divided by the square section across the cable diameter d, which is

CL = L x pi x (r2² – r1² / d²

/ d²

So, for a simple drum on a 40mm former and 70mm outer diameter (leaving the spandrel section below the deck, adjacent to the hull, for the take-off gear), gives

L = 150

r1 = 20

r2 = 30

d = 2

CL = 150 x 3.142 x (900 – 400) / 4

= 58,912mm

= 58.9 metres

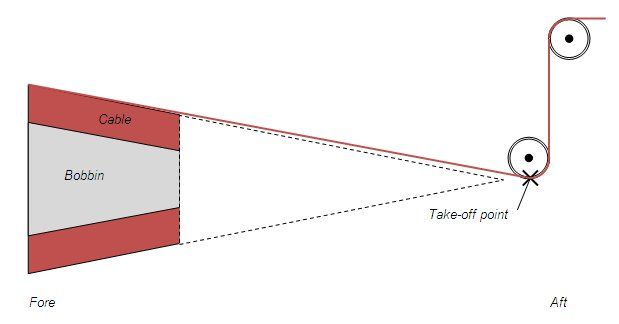

SPOOL

For a tapered spool, the angle of taper is given by the minimum radius 20mm and the 750mm (30-inch) take-off distance. 20mm in 750mm is 4mm in 150mm, which gives the minimum taper. So design with a 5mm taper, giving the bobbin a tapering in radius from 20mm to 25mm (diameter 40mm to 50mm).

Now because the take-off gear is axial, we can use almost the whole diameter available for the outer cable radius, so this will taper from 30mm to 35mm.

I don’t propose calculating the precise volume without knowing that this is the scheme to go for, but will estimate is by taking the average radii of the tapered spool and using the drum formula above.

So, for this approximation:

L = 150

r1 = 22.5

r2 = 32.5

d = 2

CL = 150 x 3.142 x (1056 – 506) / 4

= 64,804mm

= 64.8 metres

So, either way I reckon you’ll get around 60 metres in that volume, slightly more with the tapered spool. Is that enough?