Paul

This is a tricky one as you point out. Sometimes tools that can do everything are not the best for doing anything.

I have a Billings building slip which comes in kit form.

I built it and that was it. I have never used it and can't see myself doing so. The channel for the keel fits one size only and has to be packed out for thinner keels. Likewise the support for the stem. The sliding piece that is used to locate frames can only do one at a time and is not that accurate. Click here to see a picture.

I have a SLEC fuselage building jig which for those who haven't seen one, is supplied as a roll of printed vinyl to stick on a board of your choice. There are adjustable plastic supports and these are held by machine screws into captive nuts in the board. When I ordered mine I double the number of supports and added many more fixing points. I was glad I did.

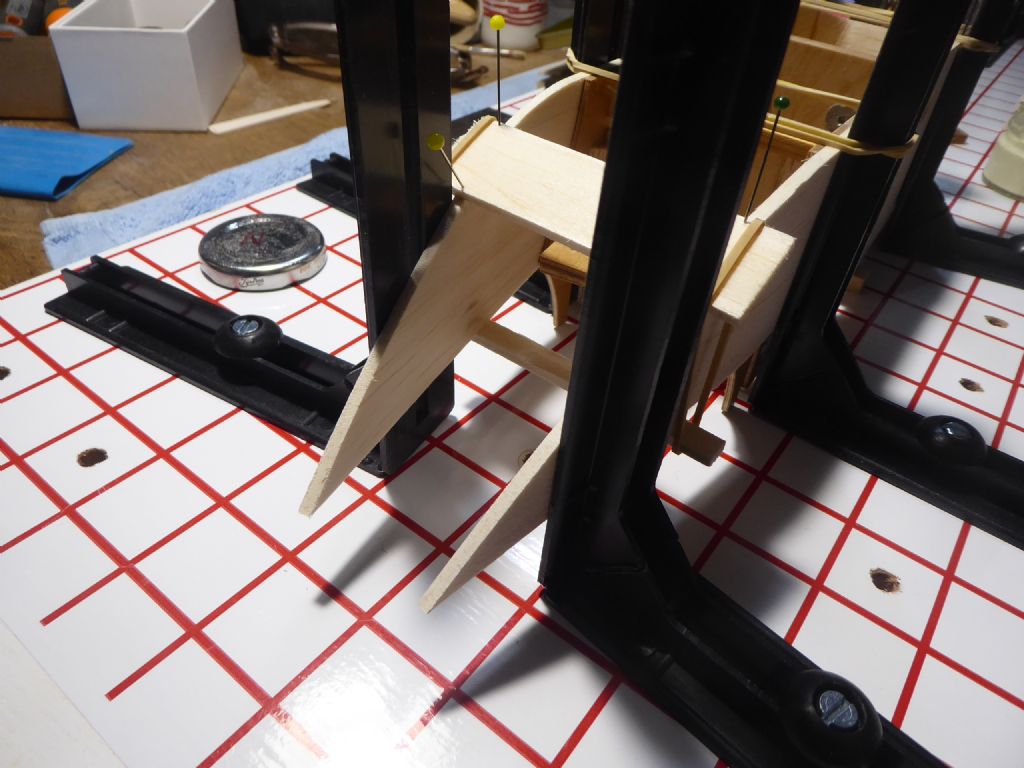

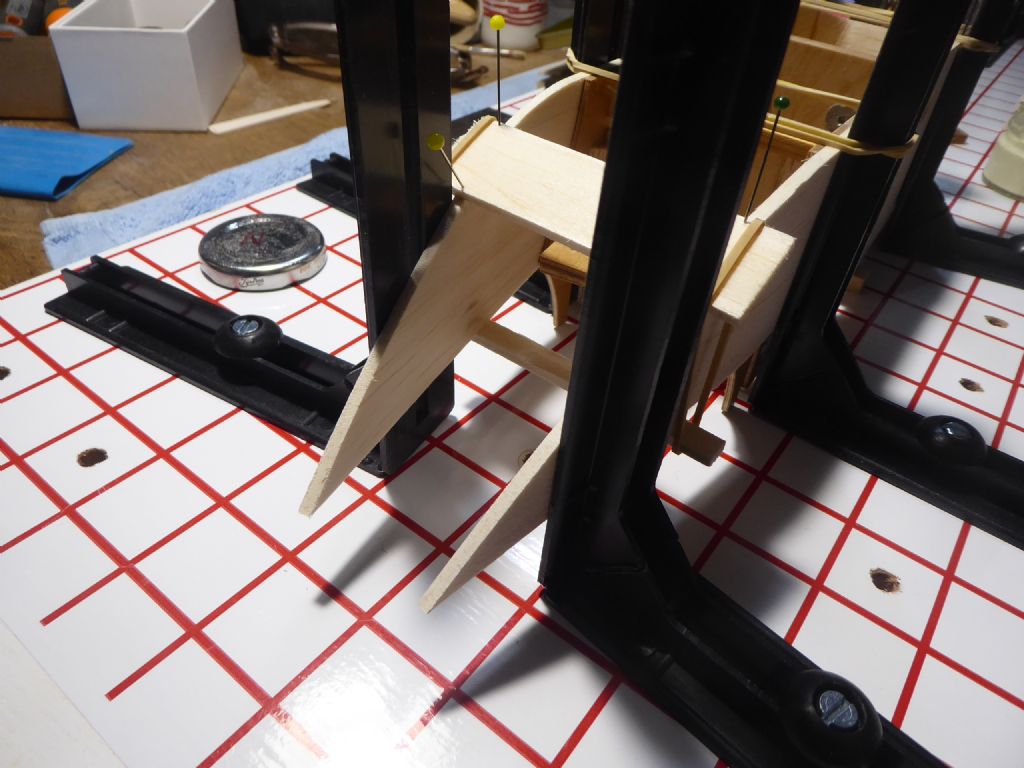

Here is an aircraft fuselage in the jig and you can see that the supports can be used in any direction you like.

Here a nacelle is under construction which ended up quite boat-like.

And here the finished fuselage is back in the jig so I can line up the wings and tail plane exactly at right angles before fixing. So is it quite versatile.

The basic requirement has to be a good flat board and my biggest board is 1200mm x 370mm as this is the size of the SLEC jig. Of course the printed material could be cut down. I have lots of smaller boards for sub assemblies all faced with two layers of 4mm cork which seems to last forever.

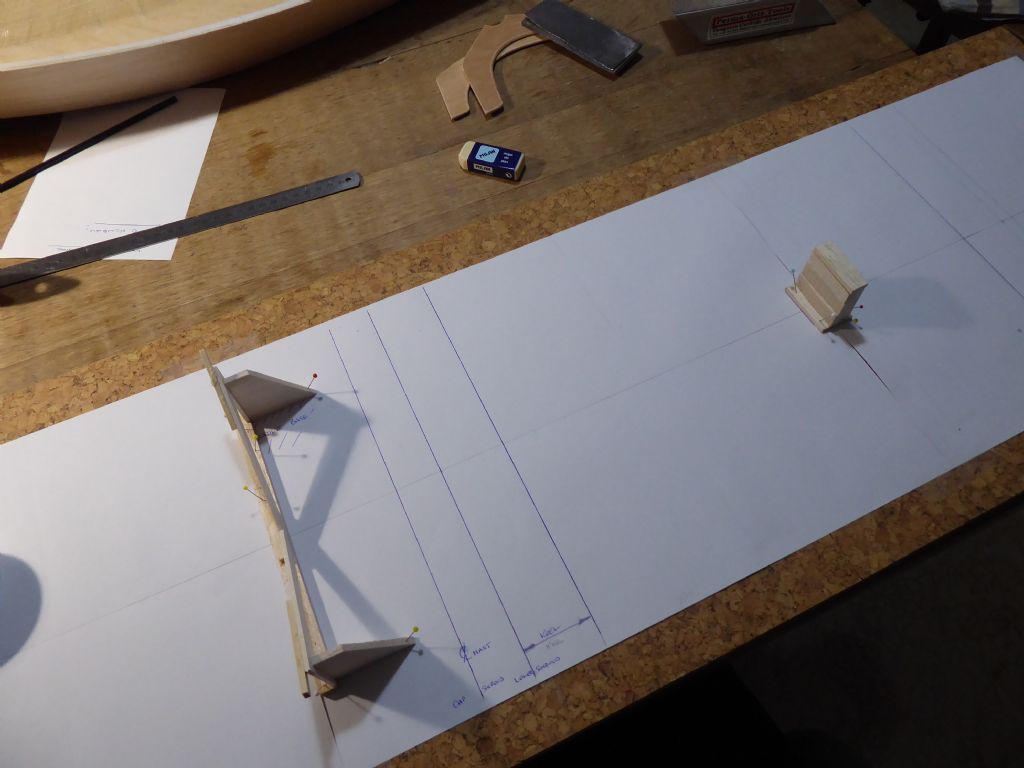

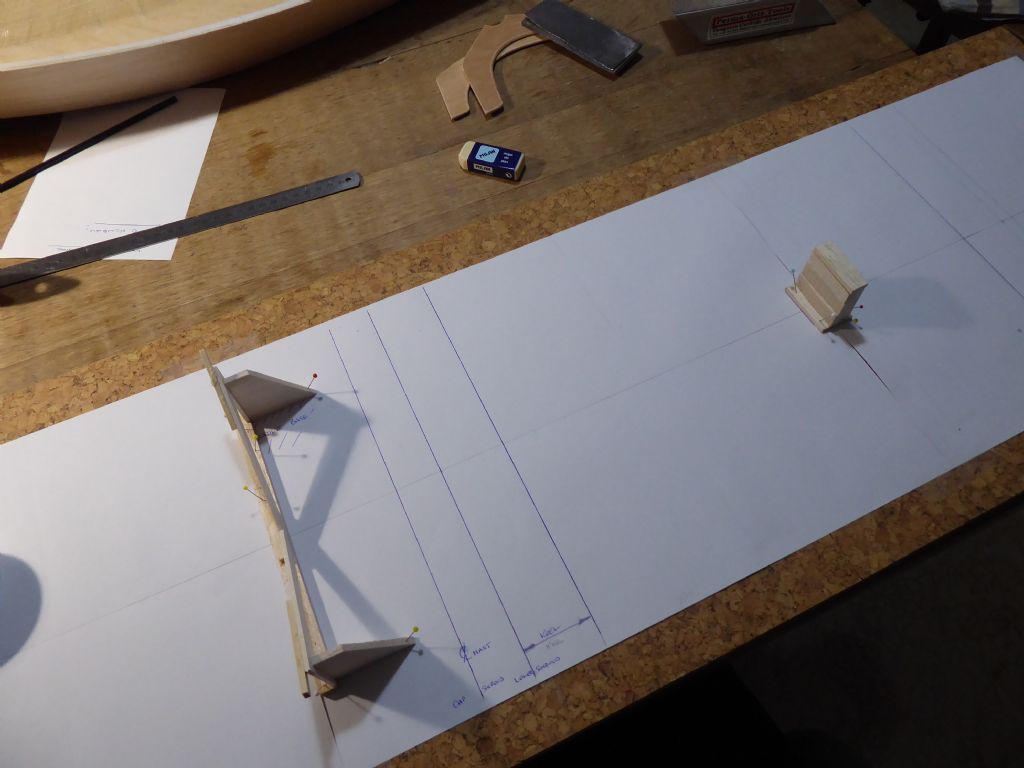

My current project "Galileo" is on this board. I made a cradle to much a chosen frame station quite well forward where there is a pronounced V and the aft, flatter section of the hull rest on a set of blocks adjusted to the correct height. With the bow exactly over the line drawn on the paper and the centrelines matched up, the model can be registered easily and with good repeatability. The cork allows me to pin other supports in place.

Like here for instance where I had to take out a bit of twist.

I suppose for me the best solution would be a good board and a "kit" of parts that I could adapt to make the necessary supports. Once the shape of the boat is stable you can move it around as much as necessary.

I suppose most boats are at least started upside down.

Tim R