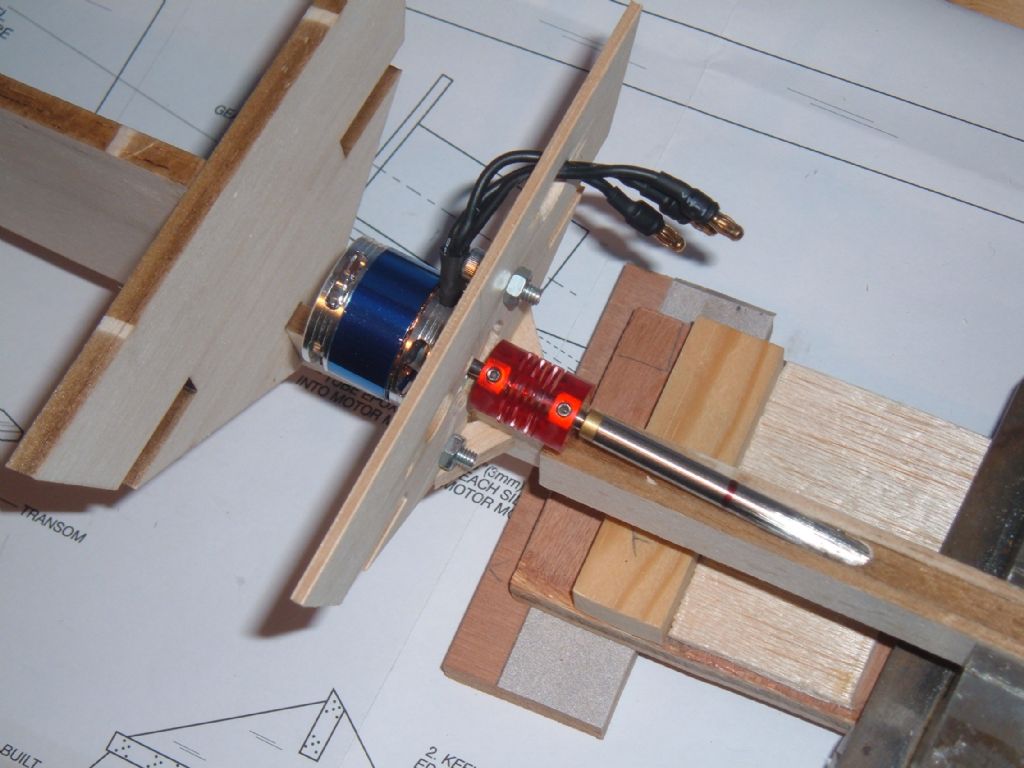

I think that you will have to fit the sides and then look at the vibration. Fitting the sides will alter the whole dynamic of the thing. As it is, the bulkhead is loose and free to wobble, even by just a tiny bit, and that will give your vibration.

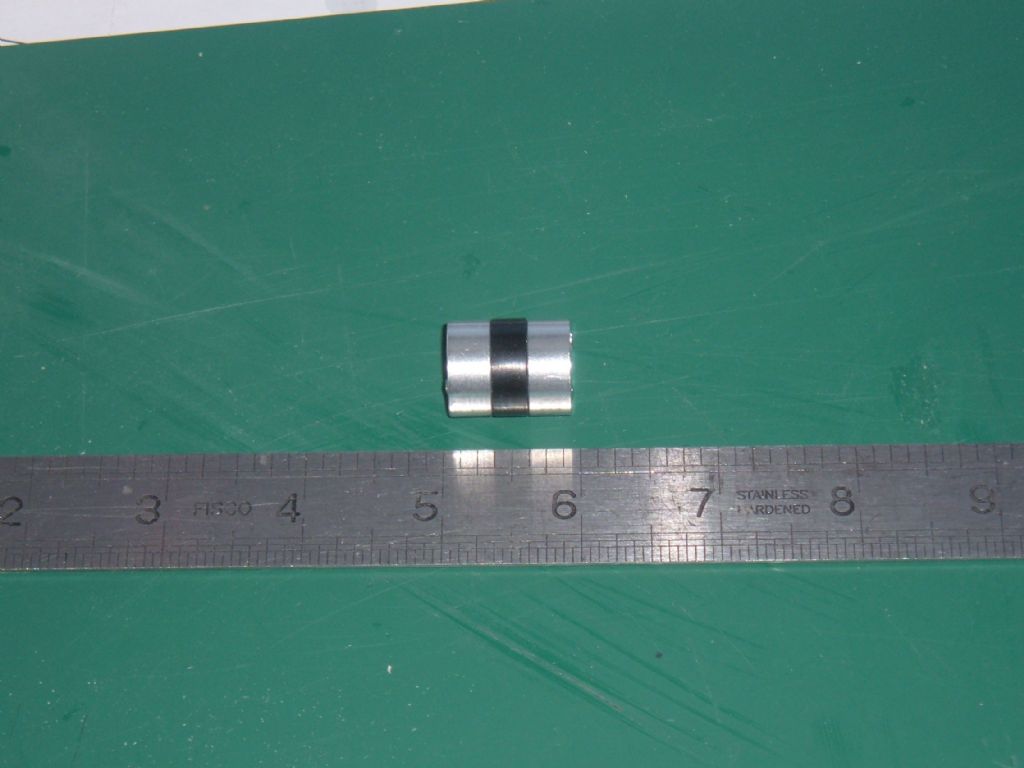

I also think that the coupling you have is simply a shock absorber, and NOT a misalignment assistor (like the u/j type, or a "Marks models" rubber tube coupler) and will not help you if there is the slightest trace of misalignment. NOT that i am suggesting there is, but. it is tricky getting everything 100%. Movement within the hull structure and assorted bending motions when on the move may cause vibration, or lead to vibration periods at certan revs.

As paul suggests, the real test is in the water, as this will dampen (pun intended) everything out.

Mind you, I have been 200% careful in the past and still suffered. Props are a good cause of vibration on their own, let alone anything else. I have also had vibration from couplings that have not been completely accurately machined.

It is a bit of sods law. On the pond, there are several boats which perform whisper quiet, and others that buzz at a certain engine speeds, despite thier constructors taking all precautions.

Ashley.