Thanks for the info and interest.

I am not worried about the out of line shafts causing the boat to turn as you say this can be corrected from the transmitter.

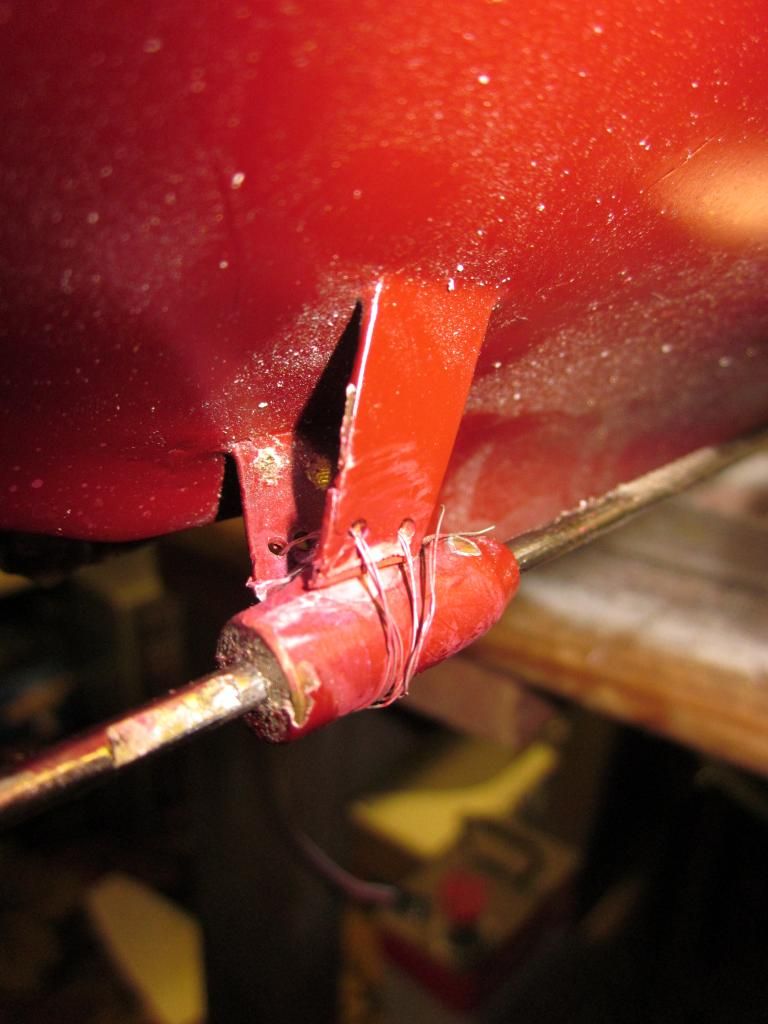

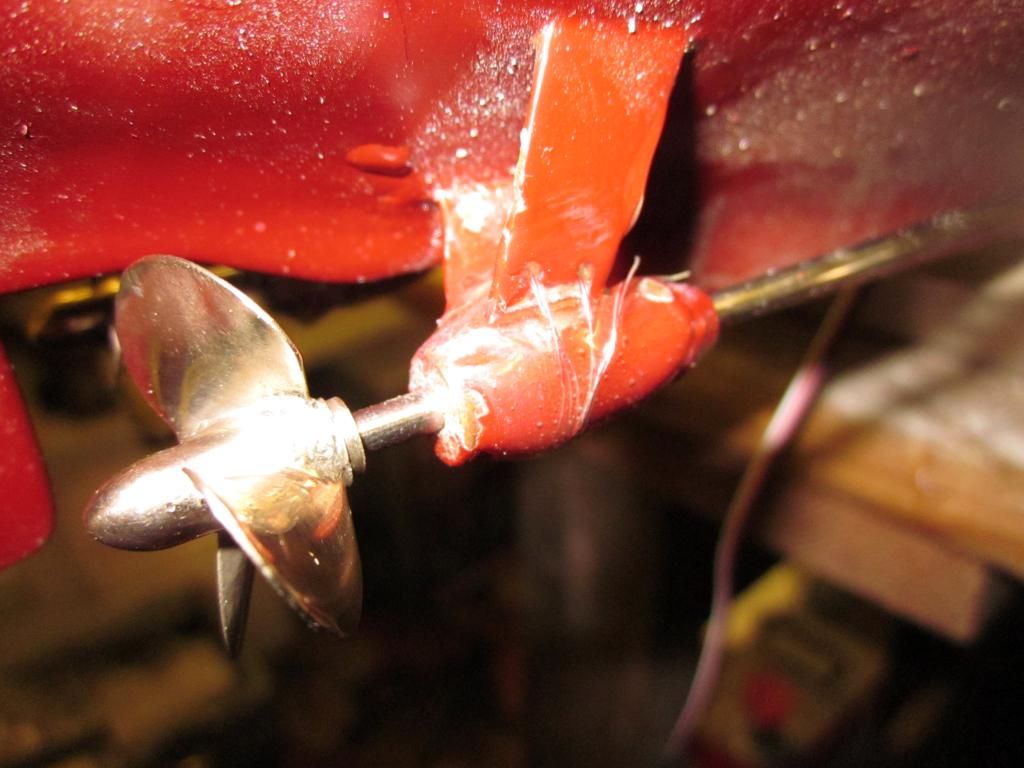

When I power up the motors individually the 2 outers run smoothly and quickly, however the 2 inners run much slower and are obviously under great strain, this will obviously make the motors run very hot and potentially cause them to burn out quick quickly – Not ideal. When the shaftas are removed from the rear A frames the motors run quickly and smoothly and when pushing the shafts back into the A frame casings it is very obvious that they are out of line.

From what I have read so far, which is precious little about this problem, there is not much point in contacting Graupner as they apparently do not offer any help.

Incidently a friend also has this model and he is experiencing similar problems and has yet to make any repairs, so it is obviously not an uncommon problem.

I really am not keen to cut the A frames and do worry about their strength when reattached and even how to reattach then successfully.

I will take some pics and upload them soon.