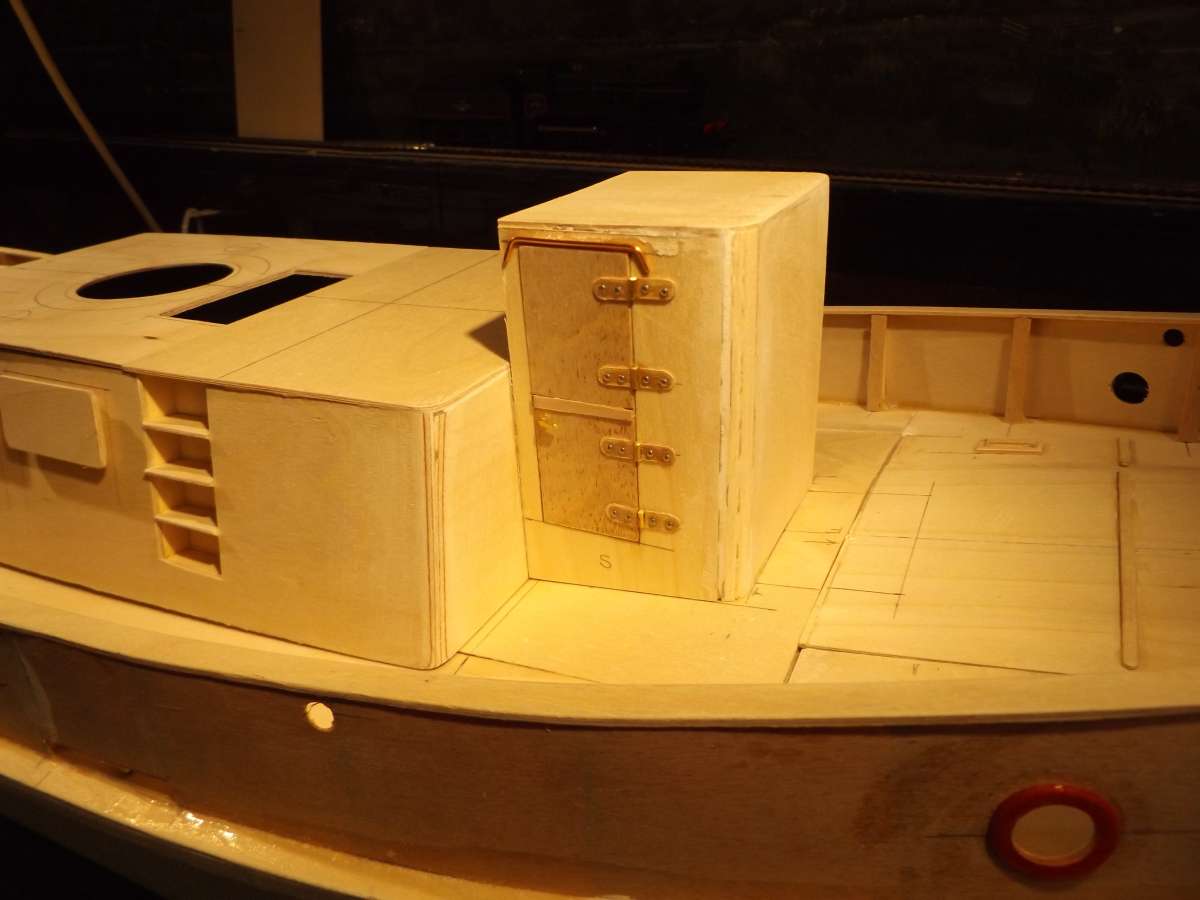

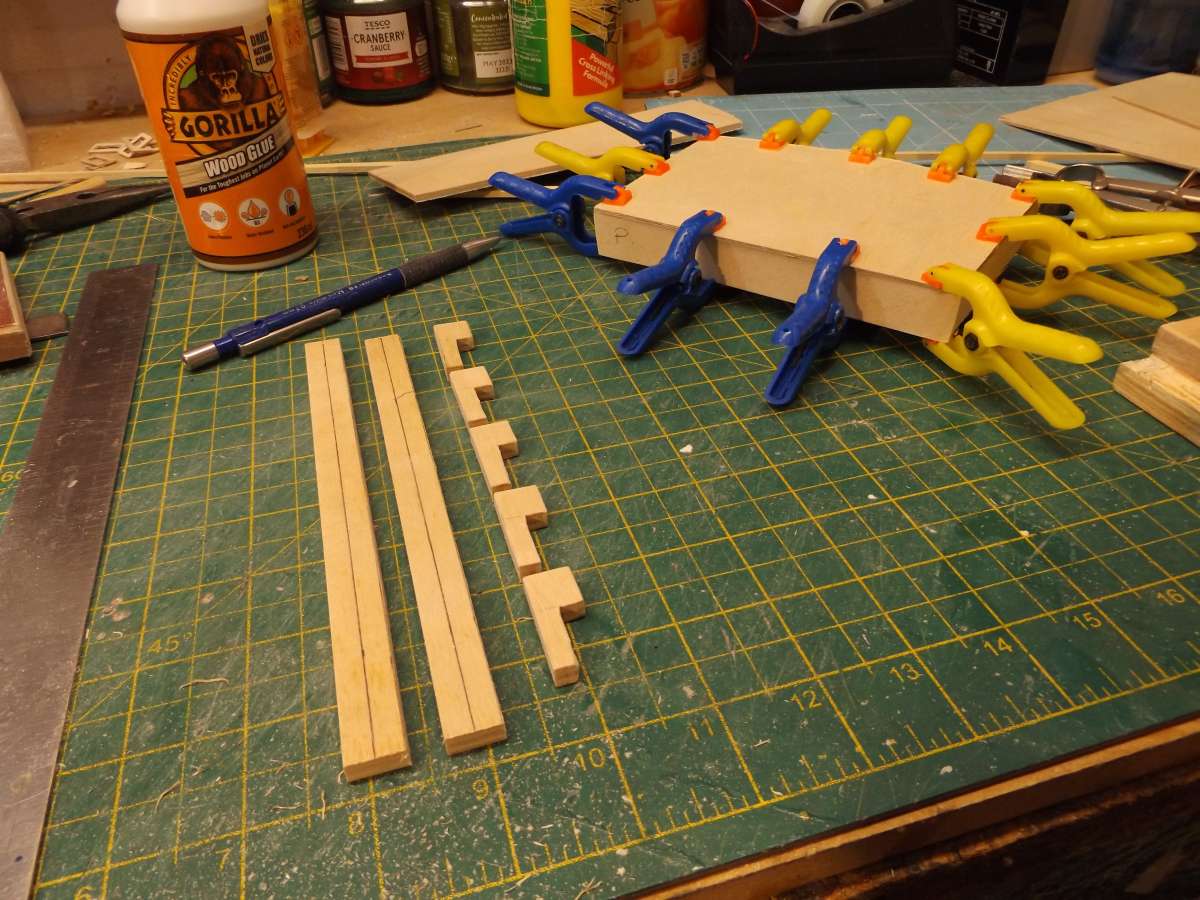

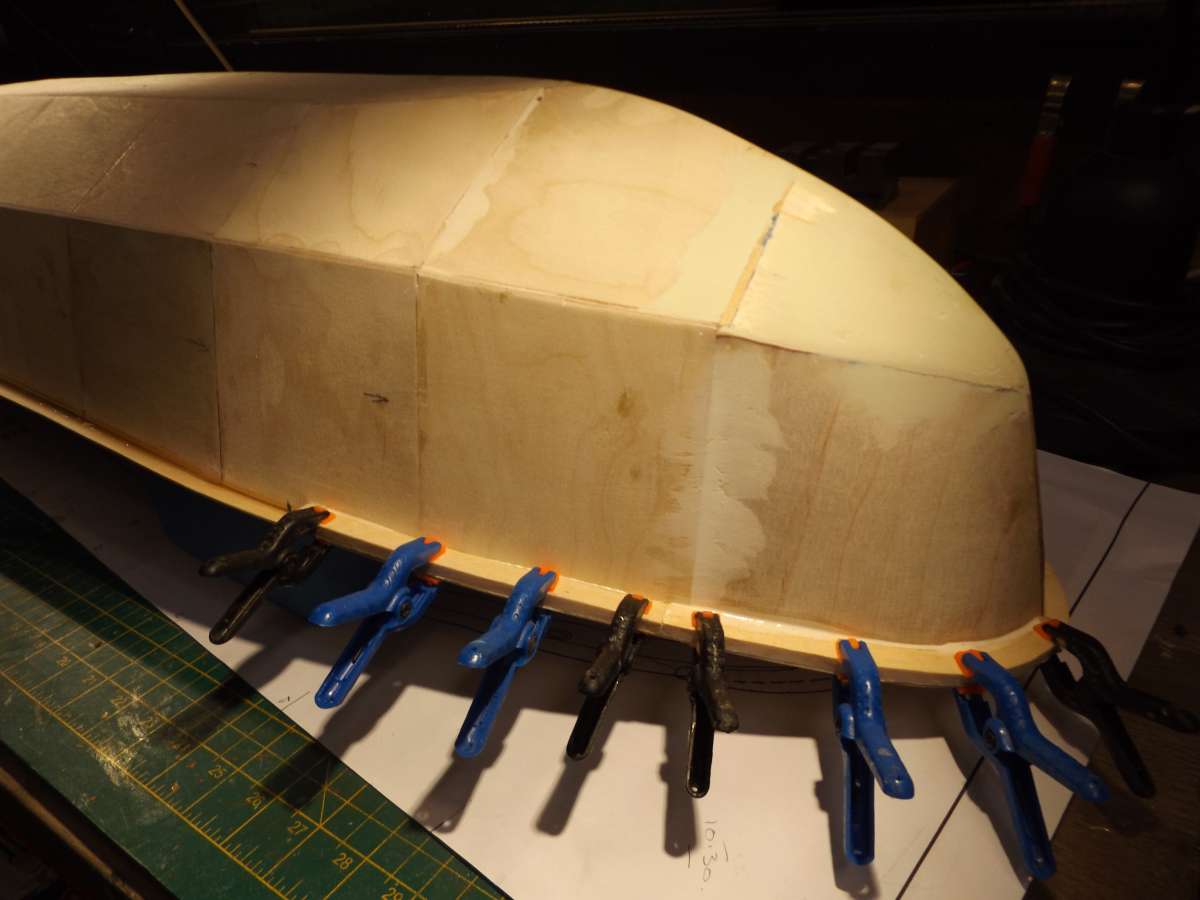

TID steam tug 42″ – PN Thomas drawing enlarged

TID steam tug 42″ – PN Thomas drawing enlarged

- This topic has 38 replies, 8 voices, and was last updated 13 hours, 30 minutes ago by

Anthony Shilson.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Code of conduct | Forum Help/FAQs

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

-

- Todays Boating 1 2 … 210 211

- 84

- 1 week ago

- John Cobb’s Crusader 1 2 … 7 8

- 1

- 3 weeks ago

Viewing 25 topics - 1 through 25 (of 25 total)

runs incredible steam powered warships, we will get there in the end but maybe later this year, I’m enjoying it so far 🙂

runs incredible steam powered warships, we will get there in the end but maybe later this year, I’m enjoying it so far 🙂