ROGER SUITTER’S unique submarine

Roger Suitters with his model in late-2012

This a model of Nuclear Research No. 1, an American nuclear powered submarine conceived in 1970 by Admiral Rickover of the US Navy who is widely accepted as the father of the modern nuclear powered submarine and surface fleet. The submarine still exists today and information about it is scarce as although being intended for deep diving research tasks, it has also operated in more sensitive military roles.

Enjoy more Model Boats Magazine reading in the monthly magazine.

Click here to subscribe & save.

NR-1 is only 145 feet (44.2 metres) in length and half of its length is taken up by the nuclear reactor which is of a water-cooled pressurised type. The actual propulsion is turbo-electric with two screws giving 4.5 knots on the surface and 3.5 knots when submerged. As it is so slow, the craft is usually towed to its destination and with its crew of eleven plus perhaps two scientists, it can dive to 3000 feet and remain there for some time. The actual drive units are built into the stern hydroplane and stabiliser unit and as such present a unique challenge to building a working model.

At the time of writing in early 2013, the model has been built with the intention of being a working diving model, but currently the dive unit and drive motors have not been installed, owing to a house move. It has been photographed though, suitably ballasted and in the water, and when finally fully operational will be an unusual model submarine.

Work started in 2007 on the model, so it was very much a long term and challenging project as Roger has made masters and moulds for the bow and stern sections in particular and from those he has cast GRP parts. Along the way, thus far, things have gone wrong as well and it has been a challenge for Roger to get this far, but that is one of the joys of scratch building.

The model

The scale of this model of NR-1 is governed by having a 100mm diameter clear acrylic tube for the centre section of the hull, so determining the scale of 1:36. Having such a tube for this part of the model is of course very handy for installing a dive unit, but the two propulsion units will have to be outside of it unless a means of connecting the propellers though the hydroplanes to motors inside the hull can be devised, but that is for the future. From photographs and information obtained from fellow submarine enthusiasts, a drawing was created, based around the 100mm diameter of the central part of the pressure hull. To this would be added removable bow and stern sections plus the substantial styrene keel box which will contain the drive batteries in a sealed tube and a built-up top casing, also of styrene. The sail (conning tower) is also a moulding taken from a master.

Bow and stern sections

Bow

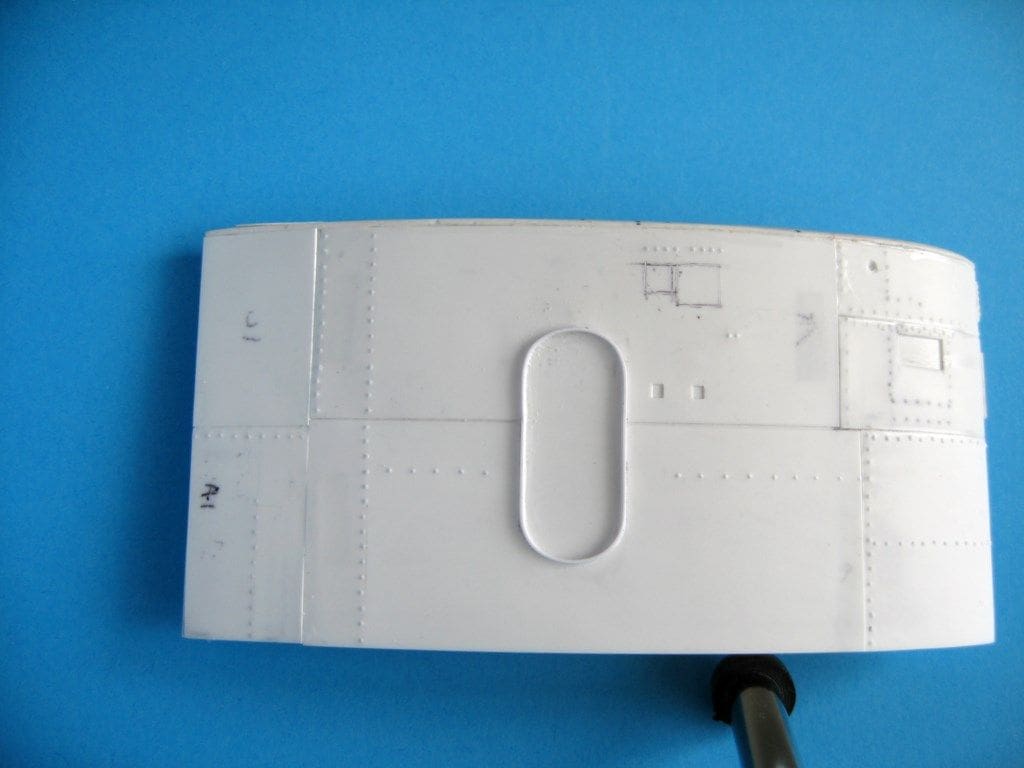

This is unusual in that it is neither like a WW2 designed submarine, nor is it like a modern nuclear powered attack boat, but is somewhere in between the two. A master was made using balsa wood frames, the shapes of which were taken from Roger’s plan and the spaces between them filled with expanding polystyrene foam. This was shaped as necessary, covered with filler and sanded to its final profile. Allowance had to be made for a sleeve at its rear end to fit later into the 100mm acrylic tube.

This basic ‘master’ for the bow section, had detail added in the form of seabed searchlights, sonar panels, thruster outlets and of course rivets, this last feature not usually being seen on modern submarines. This relatively modern submarine actually has loads of rivets, which makes it even more unusual and a model making challenge.

Once the master (sometimes known as a plug) was complete, a silicone ‘skin’ mould in two halves was taken and the complete bow section moulded in GRP and in one unit. Silicone rubber ‘skin’ moulds were used so as to ensure all the detail was transferred to the mouldings and also to keep costs down. This flexible rubber is not cheap! Reinforced Plaster of Paris was used to support the silicone.

There were problems actually making the GRP moulding, due to low ambient temperatures and damp at the time, but a decent hollow version was eventually produced from the mould.

Stern section

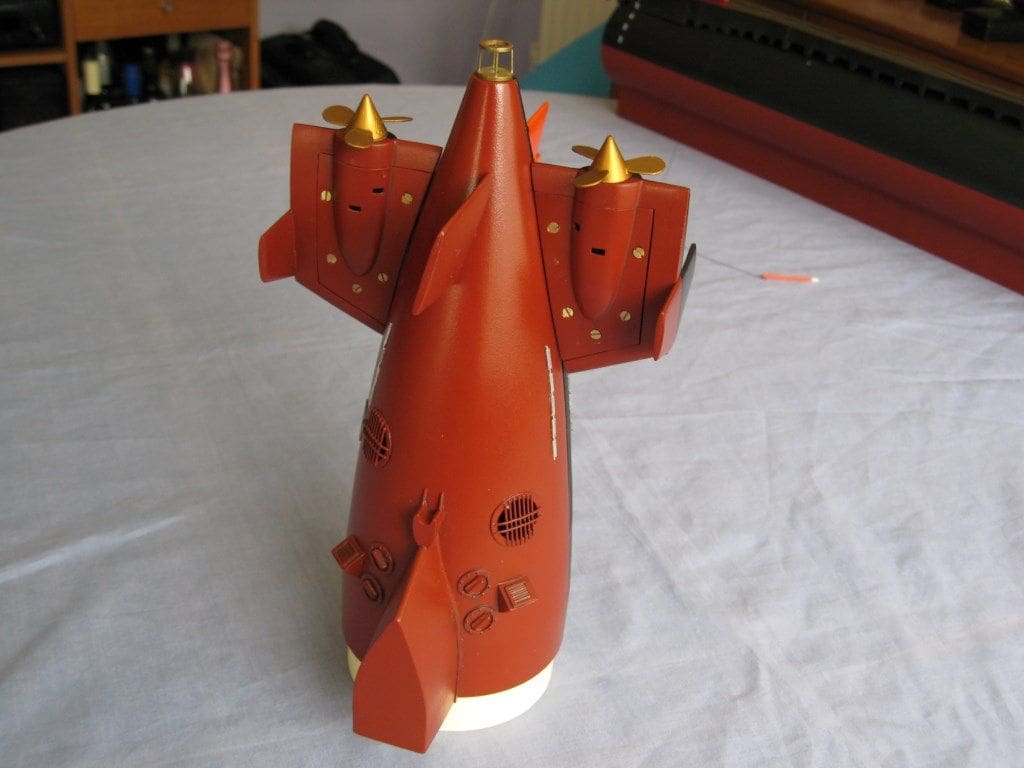

In many ways this was much easier, as the basic shape is a cone with a ‘curved cone’ if you understand what I am writing! The ‘master’ for it could could be turned on the lathe to be just perfect. Like the bow section, some detail was added to it, a mould taken and the stern cone likewise made of GRP. Joining it to the main central tube was in much the same way as for the bows, using a sleeve to slide into the 100mm acrylic tube. The real challenge, was later making the hydroplanes and stabilisers and ensuring they were perfectly in alignment with the axis of the hull.

Keel

This is basically a box section of styrene fixed to the bottom of the hull. What makes it different is an aluminium tube (from a domestic car pressure washer) that is in the centre of this external keel, running its full length and able to be sealed at both ends, in which a line of sub-C NiMH batteries can be installed. This of course means that the keel also contains some of the ballast, making for good stability. The full-size NR-1 actually has wheels, so that it can also roll along a smooth seabed.

Top casing

This is quite complex, with numerous cardboard templates being needed to get all the profiles just right. Since it has lots of openings in its outer surface, care had to be taken to ensure its cross-members would not appear immediately behind a hole. This complete unit is fixed as once piece to the central tube, whereas the keel is in three parts joined separately to the bow, central and stern sections. Care had to be taken to ensure that everything was in perfect alignment each time the model has to be reassembled. To do this, Roger made sure nothing could be reversed, the tubular butt joints were perfect and additional alignment pegs built into, and onto, the sections means that there is no room for mis-alignment.

Stern stabilisers and hydroplanes

As mentioned earlier, the propulsion units and propellers are mounted on the moveable hydroplanes. For all the sections of these, masters were made and moulds taken from which resin pieces were made. It was possible therefore to make hollow mouldings for where the motors should go. Sections of the whole assembly are removable, being held in place by screws out of the normal line of sight by being underneath. Getting everything square was a nightmare, but Roger got there in the end!

Sail (conning tower)

Following standard US Navy principles, this has the forward diving planes mounted either side of the ‘sail’. As for the other principal parts of the model, a well detailed master was created, a mould made and a resin casting produced. The rivet and panel detail is a key feature and Roger has successfully replicated it all. The NR-1 logo on the conning tower is produced by Roger on a computer, the unusual font being hard to replicate.

Painting and assembly

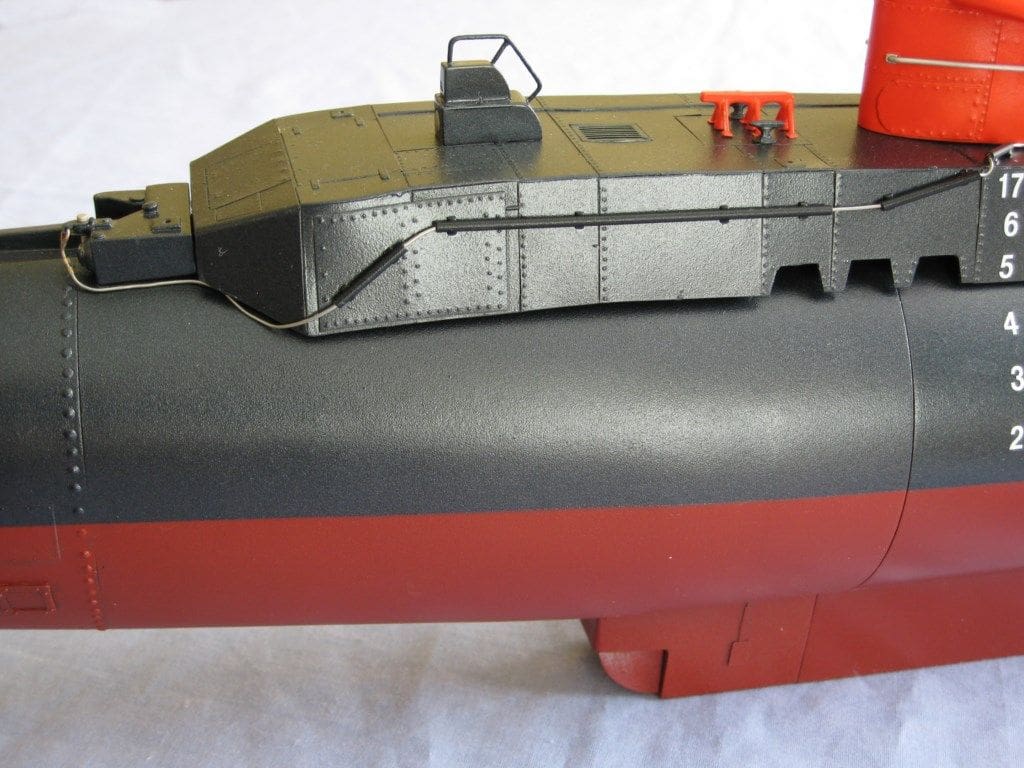

Having a black and red oxide hull, together with a red conning tower, certainly makes the model stand out from the current all black colour scheme of modern naval submarines. Nothing more exotic than car accessory shop standard aerosol spray cans were used where possible.

The model is now complete, but only as a static model, although it has been ballasted and floated for photographs. The dive unit and motors have had to be put ‘on the back burner’ whilst house moves are underway in the winter of 2012/2103, but in due course more will be published and possibly a full feature article.

(This Readers’ Models article has been prepared from notes that Roger supplied to the Editorial Office. He hopes to have a comprehensive in depth Feature Article ready for submission to me later in 2013 – Editor)