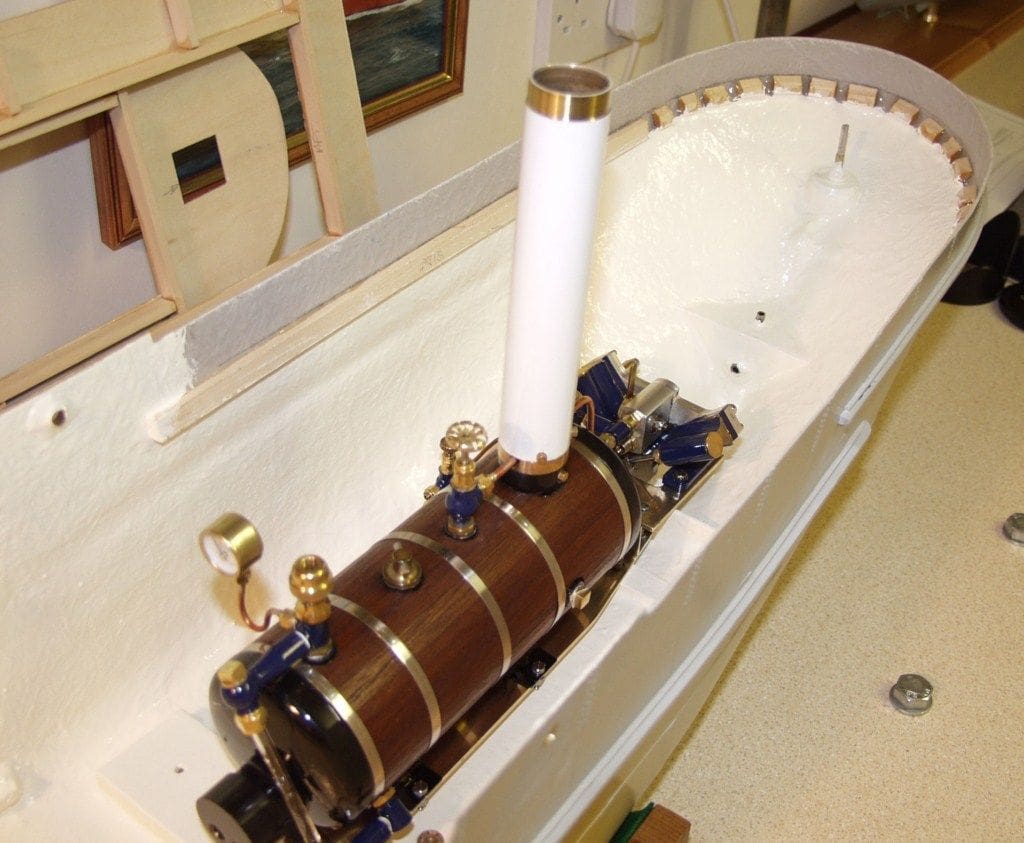

RICHARD SIMPSON’s series on model steam plants

Testing shouldn’t be shied away from and there is no reason to be scared of a steam plant, so we can all continue to enjoy watching steam models on the pond and pass down this fascinating part of our hobby to future generations. Here are two steam powered launches to demonstrate just what makes it all worthwhile.

Enjoy more Model Boats Magazine reading in the monthly magazine.

Click here to subscribe & save.

After so much has been said about testing and certification of model boilers in recent years, there still seems to be a degree of uncertainty even to the point of fear regarding the subject and unfortunately the response in some modelling groups and local government organisations sometimes seems to be along the lines of ‘Risk Avoidance’ rather than ‘Risk Management’, even though there is probably far less risk involved than there is with some electrical installations! Consequently I think it’s worth taking time out this month to try to clarify some of the points which may help modellers to understand the current requirements for model steam boats in particular.

A bit of history

Prior to 1st January 2006, all relevant bodies concerned with model boat steam plants such as insurance companies, clubs, local councils and even the Health and Safety Executive, had their own set of rules. This was all very difficult to understand and comply with, thus putting a lot of people off this sector of our hobby. A side-effect of this was that there were some who simply ignored the rules in the knowledge that often nobody really knew what was going on, and so no one could really hold them accountable!

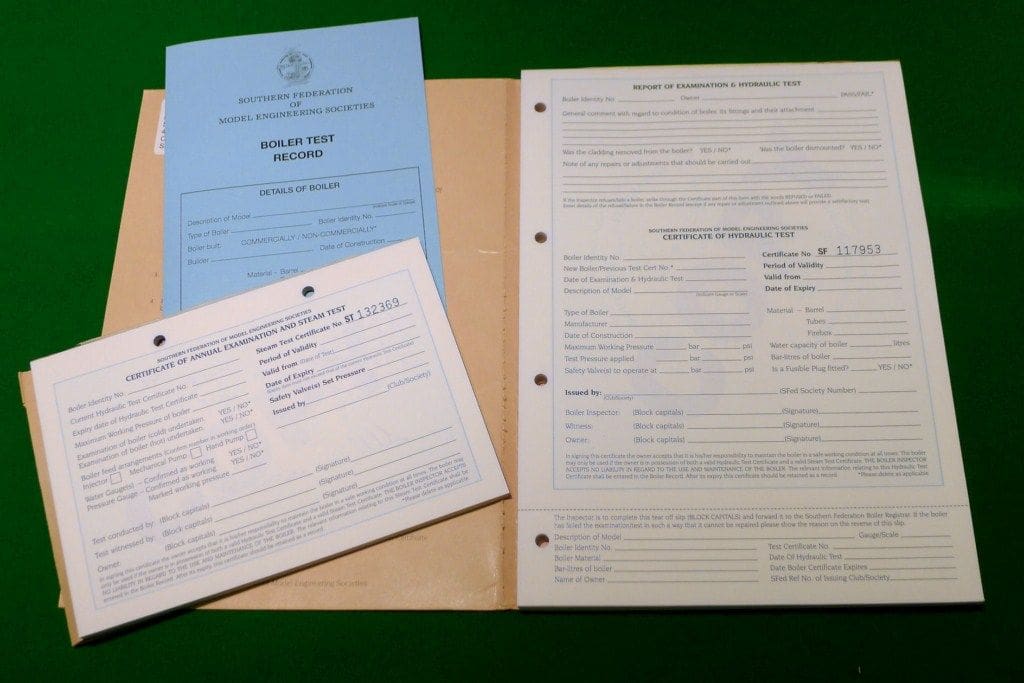

As of the 1st January 2006 these organisations all got their heads together and declared a set of rules and regulations for model boilers. These rules have been accepted by the Health and Safety Executive, most of the big insurance providers and most modelling organisations, so it is now far easier for everyone to know just what the rules are and therefore who is not complying with them. These rules were compiled into a single book, now known as the ‘Blue Book’, which was accepted and adopted by many organisations except the Model Power Boat Association (MPBA), who maintain their own set of rules which can be seen on the MPBA website under ‘Technical Notes’.

The unfortunate bottom line with the ‘Blue Book’ rules as of January 2006, was the 1.5 bar-litre requirement, which basically stated that anything above this level required regular pressure testing.

The bar-litre requirement of the Blue Book

If you take the capacity of your boiler as the total internal volume in litres and multiply it by the working pressure in bar as stated by the manufacturer, you will determine the bar-litre figure. For example, a boiler of 500ml capacity with a working pressure of 5 bar is a 2.5 bar-litre boiler.

So, a limit of 1.5 bar-litres unfortunately meant that only Mamod and Wilesco type or other ‘toy’ boilers were exempt, so the vast majority of model boat boilers required pressure testing on a regular basis.

However in 2007, pressure (pun there!) exerted resulted in a reassessment of the requirements and the bar-litre rule was reset to 3.0 bar-litres, which now meant that about 80 to 90% of model boat boilers were below this level. Consequently if your boiler is less than the 3 bar-litre limit you are exempt from the pressure testing regulations. However, it is still recommended that safety valves are tested at least once every 12 months and the boiler and pipe work installation should also be checked at least every 12 months or so. This is not to say however that all insurance companies accept these standards and even some clubs have their own rules for their steam members, so it is still not quite as cut and dried as it may seem. Also of course, any event run under the auspices of the MPBA requires you to comply with their certification process, even though you may be fully certificated under the ‘Blue Book’. The MPBA technical papers on their website as of May 2011 (www.mpba.org.uk) also state that:

‘In addition to official MPBA certificates, those issued by the Northern Association of Model Engineers, the Southern Federation of Model Engineering societies and other recognised bodies, including those not residual in the United Kingdom, will be acceptable, providing their test methods and standards are similar to those of the MPBA’.

So, in the final analysis it is the responsibility of the steam plant operator to ensure that any regulations that apply to his model in any local situation are correctly complied with.

Where does this leave us?

As regards the ‘Blue Book’ regulations, I do think now that we have gone a bit too far the other way and I think that a basic steam test and a safety valve test should be mandatory and not a recommendation. For your own peace of mind I would have your plant steamed and checked by a competent person regularly and the safety valve operation also checked annually. The MPBA rules do require regular pressure testing as well as steam testing, so attendance at any event run by the MPBA will require this certification.

Bear in mind, that the safety valve doesn’t just have to lift at a set pressure as it has also to release the pressure from the pressure vessel in a controlled manner, with the burner operating at its maximum setting. It must be tested on your own plant and with all the normal auxiliaries in operation to see if it is capable of doing its job and should any modification be made to your plant then the steam test certificate becomes invalid.

As a final comment, it is worth remembering that if you intend purchasing a boiler from any source and want to use it in a model you will usually need to have it certificated so original certificates will be required which will show what the designed working pressure is. Without this information, a pressure test cannot be completed, the setting of the safety valve cannot be adjusted and the bar-litre figure cannot be determined. Whether you intend using the model under the ‘Blue Book’ regulations or the MPBA regulations, a complete plants sold for use in boats should come with a manufacturer’s test certificate to ensure it meets safety standards. This is not unlike DIY workshop compressors and their tanks which will normally have a stamped certificate setting out the operating parameters and stating it is valid from xxxx (date) for xxxx years and advising a retest at a given point in time. If you are offered from any source, be it private, commercial, eBay, club auction etc., a steam plant that does not have basic safety certification, then it is probably wise to ask the question; ‘Why not’?

Of course, in the case of secondhand units, it may be because it has just not been used for some years, however you have to think about what will be required to get it tested and the absence of a stated working pressure will be a significant challenge. Even though boilers below the 3.0 bar-litre limit are exempt from pressure testing according to the ‘Blue Book’, all commercial products of any sort nowadays usually need to comply with standards of some sort or other.

I hope this has helped to clear one or two things up and to put a few more modeller’s minds at rest. At the end of the day certifying model boilers really isn’t a big deal and we shouldn’t be scared of it.