PHILIP BELLAMY with a few thoughts

With age, some sort of aid was becoming necessary to help carry, launch and retrieve my model boats, so as to minimise the damage that can occur to the model and very possibly myself. The local ponds in Switzerland are not the easiest to access, so transportation is necessary from the car to the water. My models vary in size from 700mm to over 1800mm length and from 2kg to over 10kg in weight, so different devices were constructed for the task.

In the beginning….

Enjoy more Model Boats Magazine reading in the monthly magazine.

Click here to subscribe & save.

The first device was originally a Silver Cross style pram (remember those?) which had a removable carry-cot. When I purchased this pram from a secondhand store, I was lucky enough to find someone at the same time who just wanted the carry-cot part, so this was resold on the spot and thus I was left with just the chassis! Two simple boards were made, retained by a similar fastening as was the original carry-cot. On the top deck I could carry any of the larger boats and on the lower level a smaller one if needed. The bottom wire tray was adequate to carry a couple of transmitters. This was not perfect, but solved the immediate problem.

Current launching and transport cradles

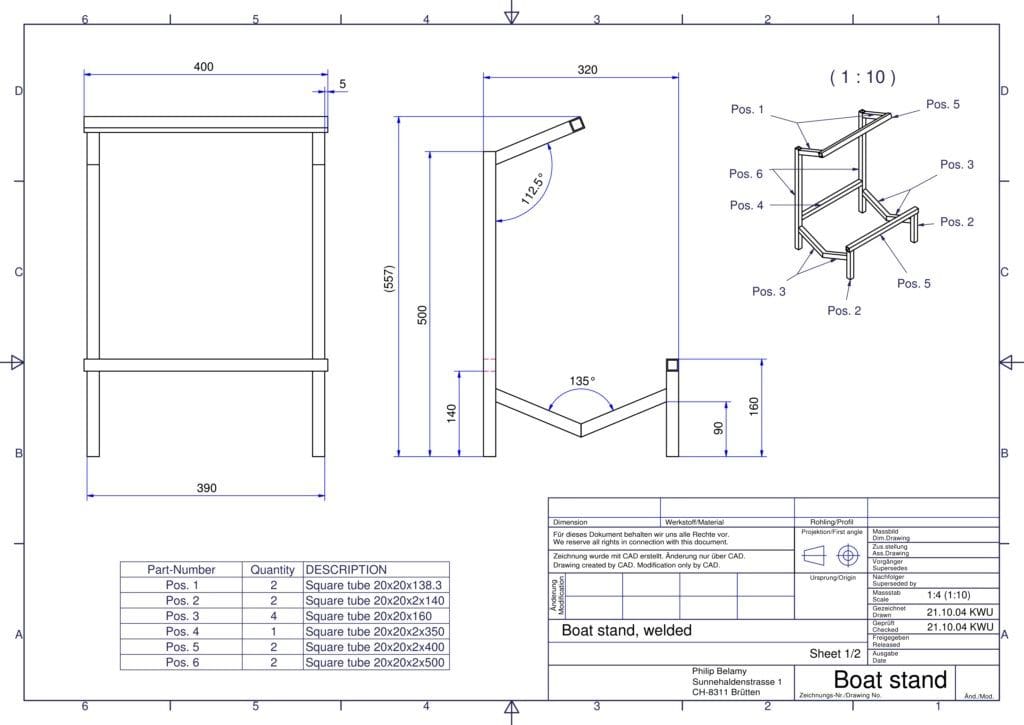

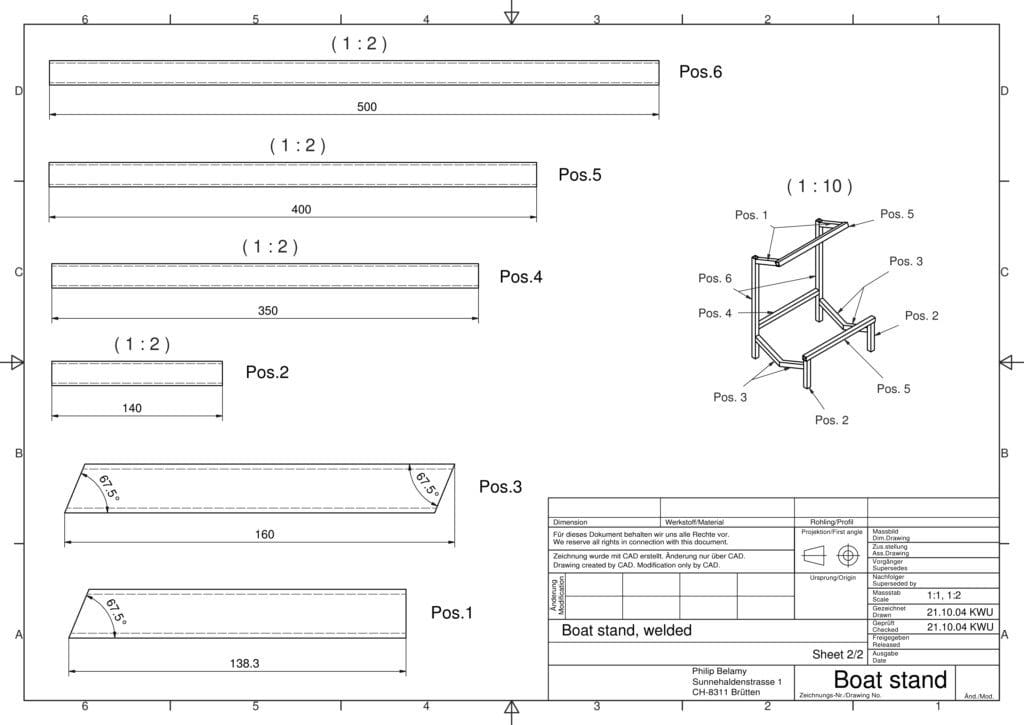

Smaller boats can be hand carried in an aluminium frame without wheels. One size doesn’t always fit everything, so there are two smaller frames that are not quite identical.

Why aluminium? Well, it is lighter than steel and does not need any surface protection for normal use and is a material of which I have experience and can weld. These two frames were made from 20 x 20 x 2mm (wall thickness) square aluminium tube and all the joints welded, but with minor modifications could be bolted together if you wished.

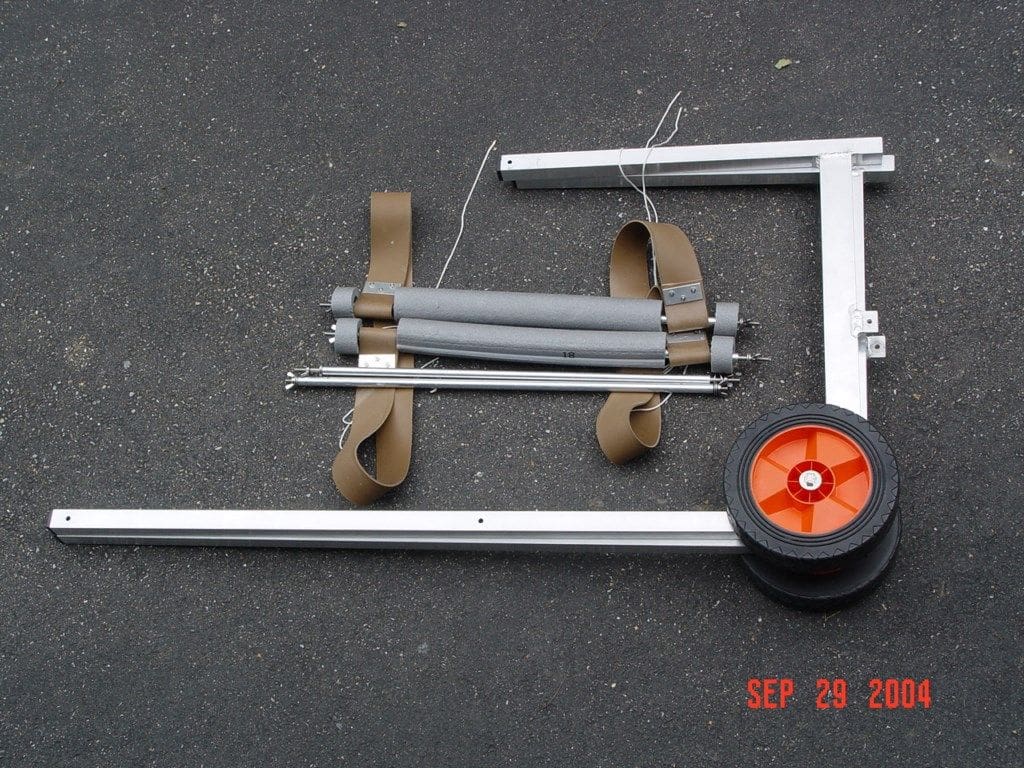

Square tube? Again, it is easier to cut and weld a straight line than a curved one which will happen if round tube is used. All the cuts are either 90 or 67.5 degrees and the welds were around the entire circumference of the tube to form watertight compartments. The ends of the other tubes are left open so that water can drain out as necessary. It should be pointed out though, that aluminium construction is not recommended for salt water operation. The largest of the three frames is of a slightly different construction, but again from aluminium. The bottom member is much deeper than the vertical tubes, which was necessary to give some added stiffness. This frame can be easily taken apart for transport and is held together when erected by threaded rods and wing nuts. The threaded rods are held in the aluminium tubes with just a roll pin and are of stainless steel. It would seem to me that today’s zinc plated steel fasteners, which are only clear passivated, are manufactured so that they do not rust as long as they are on the vendor’s shelves, but by the time that you get them home the rust has already started to attack the base metal.

Stainless steel fasteners are only slightly more expensive than plated steel versions, but not all stainless steel is truly rust proof, especially with salt water. Most fasteners are grade A2, but for more corrosive use then grade A4 should be used, the latter being obtained from ship’s chandlers.

Foam plastic pipe insulation has been used to protect the models from their normal display stands, but on this cradle the rubberised canvas support straps for the hull are similar to that used by some chair manufacturers. With just simple sling supports, it will be found that the model rocks too much when being transported, so the lowest point of the catenary is tied with some nylon cord to the lowest cross member, so the sling is now nearer to being a vee shape. The wheels are plastic and are bought as spares for a lawn fertiliser tool, their axles also being from stainless steel.

The dimensions for these cradles will depend on the models to be transported and of course the room that one has in one’s vehicle. Certainly do not make them too narrow and don’t forget to take into account the thickness of the foam insulation when determining the width and height of the cradle.

Stands and tools?

A couple of thoughts about these.

Display stands

These are the same basic design for all the boats and are in the form of a tray with raised vertical sides and ends. The stands are made from 10mm plywood glued and screwed together, then varnished. The edges on which the model actually rests, have a layer of synthetic foam which does not adhere to the hull bottom.

Tools

Each model has its own dedicated set of tools and spares, usually stored in a plastic compartment box of the type found in shops such as ‘Poundland’. Also, socket head stainless steel screws for mounting items in the hull are my preferred choice rather than slotted head screws. In addition, especially made tools for working in the confined spaces of a particular model can make life so much easier. For example an extended Allen key holder, or a thinned spanner for getting to a propshaft nut deep down inside the hull may make life easier. These tools are usually cannibalised from an exiting stock tool.

(Editor’s note: Philip is an engineer by profession and welding aluminium might be beyond many modeller’s capabilities, but such frames can be bolted together, or alternatively made from copper plumbing pipe and soft soldered. The addition of wheels to the large transport and launching cradle is also a good idea)