DAVID PLEDGE goes small!

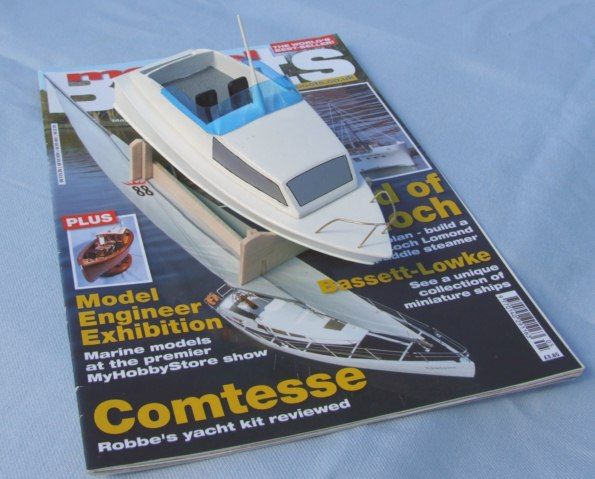

In the 2010 MB Winter Special with its centre page plan for a Fairey Huntress cabin cruiser, I noticed tucked in the editorial text on Page 5 the word ‘challenge’. Now I’m not usually a competitive type, but this challenge was different, namely to build a radio controlled model about seven inches long. Now I do consider that to be a challenge!

Components

Enjoy more Model Boats Magazine reading in the monthly magazine.

Click here to subscribe & save.

The first problem was to find a radio receiver that would fit in the hull, without the plugs and leads turning a small unit into a very huge lump. Luckily I saw a fellow Knightcote MBC member with a Planet 2.4GHz set and then had a ‘Eureka’ moment. The servo leads go in the end of the receiver making the whole set-up long and slim rather than the more conventional chunky 27 and 40MHz versions with wires sprouting in all directions. The short 2.4GHz aerial would also fit my intended hull rather nicely. Keeping excess wire to a minimum was going to be important if the project was to work. Next on the shopping list was a speed controller and an ACTion R/C Electronics P68a without the box seemed to be about the smallest available whilst giving a satisfactory performance, both ahead and astern. A visit to Howes of Kidlington unearthed a pile of broken micro-helicopter bits including small motors and servos. After a small amount of money had changed hands this junk was mine, but all this miniaturisation would be in vain if I couldn’t locate a micro-drive battery. The Component Shop offer a number of very small ‘fractional’ triple A units, but with tiny amp-hour ratings. A test run showed that at least a 10 minute run could be achieved with four half triple A 210mAh rated cells, so the project was on. Mind you, all these items still had to fit through a deck aperture whose maximum size was 120mm x 40mm. I had many sleepless nights pondering the internal layout; how to secure the equipment; would the model float; would it go, and so on until tiredness took over.

Construction

This started by acquiring brass tube and stainless steel rod for the propshaft and cutting it to length. The motor was connected to this with flexible wire sleeving and the assembly laid on the drawing to see if anything was too big as the hull at the bow is only 32mm deep, and that’s on the outside! At this point I hadn’t worked out where I could find a propeller, but decided to leave that until later as something was bound to turn up , well I hoped so anyway! Next I traced, cut and glued the balsa keel, doublers, formers, chines and deck. Diagonal planking to bottom and sides was with 1/32 inch balsa sheet. When dry and rigid, I sanded everything smooth and applied a coat of lightweight Modelspan tissue with clear dope. Initially this was thinned 50/50 and followed by two full strength coats. After hardening, and more sanding, half round styrene rubbing and chine strips were added along with 0.4mm square bottom rails to give directional stability. Once all the glue had fully dried, a rub down with 400 grit wet and dry paper was followed by three coats of white acrylic primer. Compared to this, the superstructure was simple, being of 3/32 and 1/16 inch balsa of a medium hard grade, glued with balsa cement and primed as before. Windows were cut from silver sticky tape and the windscreen fashioned, at the fourth attempt, from a file divider. The balsa seats still await their leather covering! The mast is from styrene rod and plasticard and yet to be added is a crew and steering console. Finally it was time to get the working parts installed. I had already ascertained the best location for the esc, receiver, rudder servo and batteries in the test centre facility, otherwise known as the kitchen sink. All the wires were shortened so that they would fit in the hull, save weight and not trail in the water. The esc is located by the wires and a small bearer on the bottom of the hull; the receiver hasn’t got anywhere else to go; the rudder servo does not need a lot of restraint so a 1mm ply ‘key’ secures it to a balsa base. The last item was the power source. The four half triple A units were soldered into two twin packs with joining wires to fit either side of the rudder post with a very small switch in the positive lead. The rudder is from 0.25mm brass shim, soldered to a brass post. An arm from the same brass sheet was soldered to a brass collar with a grub screw and a conveniently sized hole for the post. Did someone mention the propeller? In the end I made it myself and it’s is a tad over 12mm diameter, cut from 0.25mm brass sheet, soldered to another collar, carefully shaped with a file to look like a propeller, twisted and curved with pliers to give it profile and pitch, and all by guesswork! The last item was the front handrail assembly (pulpit) carefully bent up from brass wire. The finished model only weighs in at 63 grams, complete with batteries and paint, so I reckon there’s about another four grams still available for a crew, steering console, flag and nameplates.

On the water

A secret test trip to the club water had shown that the model worked, could sail out-of-sight and had sufficient power to last for 18 minutes on one set of those tiny batteries. I was really pleased with this, so the finishing touches such as a turquoise hull bottom and fixing the seats were carried out before heading off for a Club Thursday morning session with my peers. It had a fair turn of speed, being able to harry yachts and tugs with total disrespect, and nimble enough to keep out of their way! Then someone said; ‘Wot, no working lights’!

Weight data

Motor: 8.3g

Receiver: 4.8g

Esc: 6.3g

Batteries: 16.6g

Servo: 4.8g

Propshaft: 3.1g

Hull: 8.9g

Cabin: 7.7g

Total 60.5 grams

(Phil Button supplied this article on behalf of David Pledge. I was happy to arrange a voucher for £100 worth of goods from MyHobbyStore to David as promised in the 2010 MB Winter Special to the first person who could build a model from the reduced size plan as printed in that issue – Editor)