Richard Simpson with Part Three of his six part mini-series

.jpg)

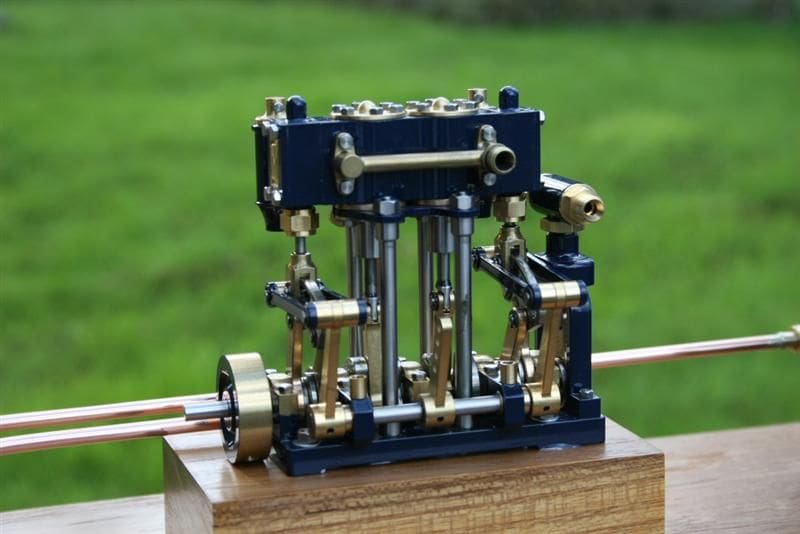

Some of Richard’s Engines set up for practical display

Introduction

I think above all else that it is the engine in a steam plant that really gives it a degree of fascination and attraction which an electric power plant can never hope to match. It is so difficult to define just what the attraction is, but a major part has to be the fact that you can see it all moving, as well as knowing that you have a perfect miniature reciprocating engine, including pistons, crankshafts and connecting rods all spinning around in your model. When I was at college in Liverpool we had an old steam reciprocating tug engine that we connected up to a painfully inadequate steam generator, but it was enough to turn it over. The sheer delight of just watching this engine going around will always remain with me as one of my favourite moments of my training and trying to lubricate the cups in the open crankcase just gave us all such a buzz.

Enjoy more Model Boats Magazine reading in the monthly magazine.

Click here to subscribe & save.

Once again the first consideration with your engine is what it has to do and hence can you get what is needed into your model. Most manufacturers will stipulate a displacement that the engine will propel or a propeller size as a guidance, but you will still be left with choosing which of the many possible configurations suits what you want. Once again you have to define for yourself what you need the engine to do as regards the involvement at the pond side, reliability, ease of maintenance etc.

Configurations

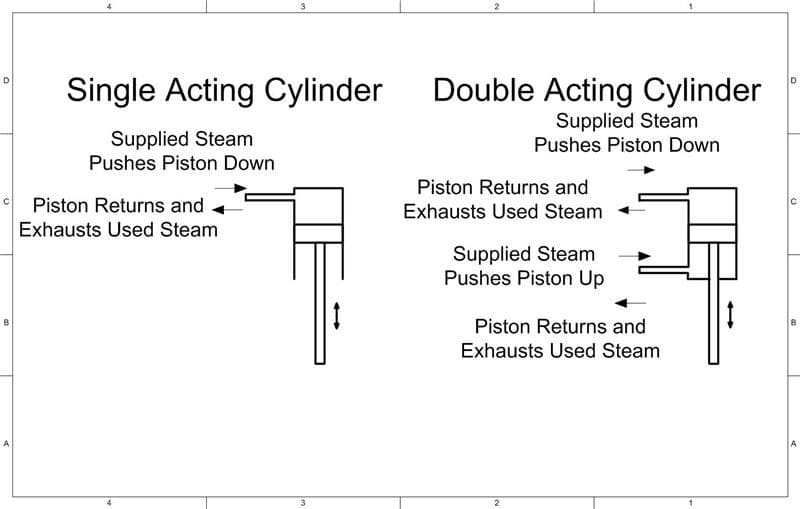

To help you decide what you want to fit to your boat you first of all need to know a bit about the limitations of each type of engine available and hence what they can and cannot do so before we go any further have a look at Diagram One to help understand the difference between a single acting and a double acting cylinder.

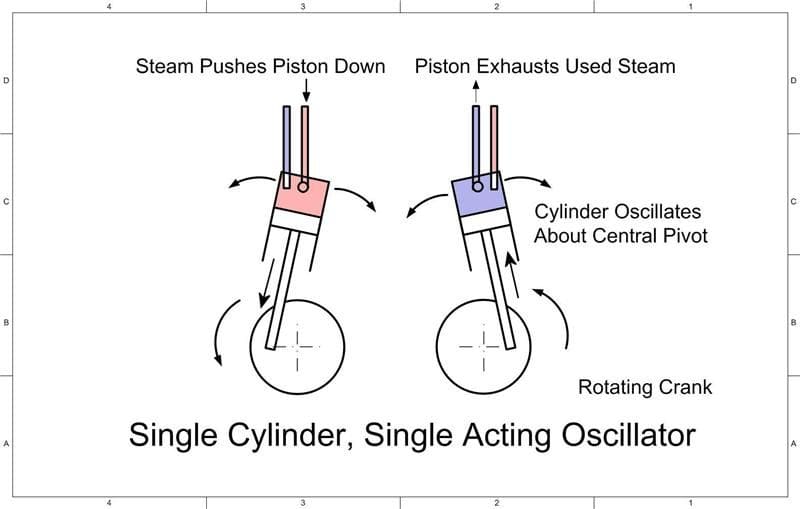

Single cylinder, single acting oscillator

The simplest configuration has to be the single cylinder, single acting oscillator, Diagram Two. This engine has a cylinder that oscillates from side to side, which in turn opens and closes the supply and exhaust ports drilled into the cylinder and matching up with similar ports in the main frame. The piston and rod is solid, hence there is only a bearing at the crank throw, so the rotation of the crank moves the cylinder from side to side. It is this operation that makes the engine an oscillator type. The single acting part of the definition refers to the fact that steam is admitted to the top of the piston only. The bottom of the piston is open to atmosphere and there is only one power stroke per revolution, relying on the flywheel to rotate the engine through the exhaust stroke. This type of engine will not self start, so consequently it cannot be reversed. You will find engines such as this, Photo 1, in some of the simplest model boats of the type that are placed on the water with a fixed rudder and allowed to sail across to the other side where they can be retrieved.

The next stage up the evolutionary ladder is a twin, single acting oscillator. Two pistons arranged on a single crankshaft of either an in line, horizontally opposed or a Vee-configuration. Ports are arranged to both cylinders supplying and exhausting the steam which connect to common inlet and outlet pipes. Once again there is a possibility that it will not self start, but now there are two power strokes per revolution, giving a bit more useful output, but it still cannot be relied upon to be reversible.

Twin, double acting oscillator

Now to a considerably more common arrangement for modern model boat use and that is the twin, double acting oscillating engine, Photo 2. The significant difference here is that the lower part of the piston is sealed with a cover and a shaft seal, so now in addition, steam is admitted to the lower part of the piston, hence double acting. For a twin double acting oscillator you will have four power strokes per revolution, so the cylinders can be arranged to ensure there is always one on a power stroke. This engine is therefore self starting and hence reversible, so can be used in conjunction with a pressure regulating valve to control both speed and direction. Once again you will find these as either horizontally opposed, in line or Vee-engines with the Vee being the most compact in a longitudinal direction and the in line version being narrower and hence better suited to a finer stern arrangement in a model.

One of the biggest concerns with an oscillator is the fact that you are transferring steam to the cylinder through ports machined into two sliding faces. There is always going to be a possibility of steam leaking from these faces if they should become worn or if they are not sufficiently lubricated. Oscillators are also limited as regards performance adjustments, as the ports are not moveable and there has to be a degree of separation between the ports, so there is a dead band where steam is neither being supplied nor exhausted. The steam must also be admitted for the entire length of the piston travel and exhausted for the entire travel in the opposite direction, which does not give the best performance characteristics. This makes them slightly heavier on steam use, but nevertheless robust, simple, reliable, compact and relatively high revving.

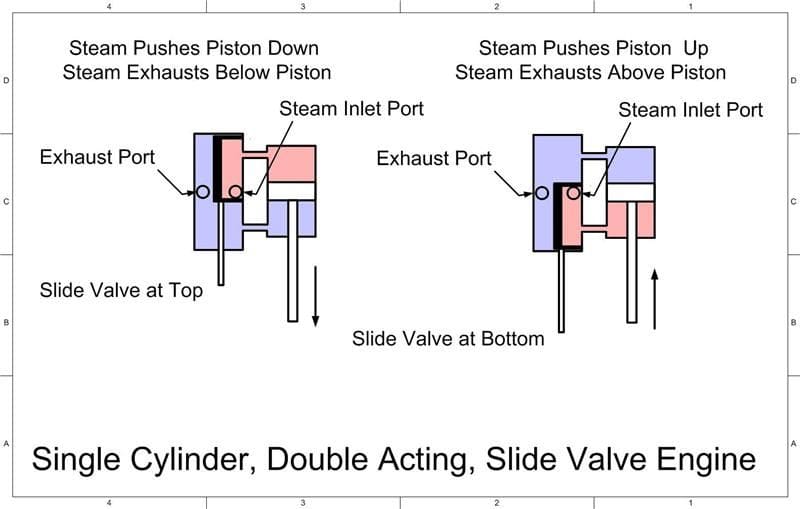

Slide valve engine

The next major type of engine is the slide valve. With this type of engine, the cylinder is fixed and the piston is moved up and down with a more normal conrod as found in a petrol engine with a bearing at the top and the bottom. Steam is admitted to the top or the bottom of the piston by use of a valve that is housed in a chest attached to the cylinder. The steam entering the chest is directed by the valve that slides up and down within the chest and either supplies or exhausts the cylinder space and this valve is connected via another conrod to an eccentric on the crankshaft as in Diagram Three. The great advantages of these engines is that there is no loss of steam at the port faces as on an oscillator, and the steam inlet and outlet can be timed to give much better performance. To pay for that however you have the added complexity of two con rods per cylinder with their associated bearings. Once again a single cylinder double acting slide valve engine would not be considered self starting, because if the engine stopped at top dead centre or bottom dead centre it would have no starting torque. The other significant characteristic though of a slide valve engine is the fact that the valve can be infinitely adjusted to admit steam at just the right time in the cycle. This will usually be slightly before top dead centre so the valve is then set up to operate the engine in one direction only. Reversing a slide valve engine requires a complex linkage that adjusts the position of the slide valve relative to the crankshaft and once again makes the engine very complicated for the modeller and uses another channel and servo for the reversing linkage as in Photo 3.

Because of the requirement of the slide valve engine to have separate eccentrics on the crankshaft for each valve, creating a Vee-configuration would be very complex and this is certainly not a common configuration. In line twins are common though and horizontal twin configurations were very regularly used as factory engines throughout the industrial revolution years.

Other engine configurations include a piston valve arrangement which uses a piston rather than a slide valve to control the steam. There was a Vee-Four piston valve model engine produced by Maxwell Hemmens in the 1980s which is now a highly regarded and sought after piece of engineering, Photo 4.

A typical in line piston valve engine is shown in Photo 5, and there are a number of one off configurations created by imaginative minds with a desire to produce something unique.

Engine Fittings

Compared to a boiler the fittings on the engine are relatively few, however they are equally significant and need a degree of understanding to ensure reliable operation.

Control Valve: A number of oscillating engines will have the main control valve arranged as part of the engine and incorporate a rotating disc valve which slides over a ported distribution face. This type of valve allows operation of the engine via a single servo from a mid-stopped position to full ahead one way and full astern the other. These valves must be looked after and carefully lubricated to ensure smooth operation and all are fitted with an adjustable spring to vary the pressure on the rubbing faces. Too little pressure will lead to leaking of steam at the valve face and too much pressure will cause premature erosion of the face and once again, leakage. Another useful thing to remember with these valves is to always try to arrange the operating servo so that the servo arm is in the same plane as the valve operating arm. This will ensure that there is no component of the servo arm force trying to lift the valve off its face and help to keep the valve sealed. Valves on slide valve engines tend to be nothing more complex that a throttle valve, operated by a servo, to control the steam pressure, and hence speed, to the engine. Reversing will have to be done with another servo connected to the reversing mechanism.

Reversing Gear: Found only on a slide valve engine to enable the engine rotation to be reversed. There are a number of different types of mechanism, but none are simple and they usually require another servo to operate. They tend to be unreliable and difficult to set up to operate smoothly, so tend not to be found in too many boats. Most modellers tend to go for the less efficient, yet more reliable, oscillator engine. Another way around this is an arrangement that I am putting together for a launch which is to use a controllable pitch propeller. With this device the steam engine does not need to reverse, so the benefits of the slide valve engine can be enjoyed without having to worry about whether it will reverse just when you need it to.

Lubricator: There are mechanically operated lubricators available, but they do require engine power to operate and by far the most common found in marine models is the displacement lubricator. The importance of this device cannot be over estimated and the reliability and condition of your engine is entirely dependant on its operation. It simply consists of a vertical cylinder, full of lubricating oil, connected via a Tee-piece to the engine inlet. As steam passes the lubricator a small amount condenses and collects in the bottom of the cylinder. This displaces the lube oil, which then enters the inlet steam flow and passes through the engine with the steam, thereby oiling all the internal steam passages. If the lubricator is allowed to run dry, your engine will not be oiled and will very soon start to wear excessively on any running surface. You must also use proprietary steam oil in these lubricators with all the required properties to do the job to ensure reliable oiling of the engine. Each time the boat is brought into the bank it is well worth draining off the water from the bottom of the lubricator and topping up with fresh oil. Lubricators are fitted with a drain valve to enable this to be done and the water can be blown out under pressure from the boiler with the engine off. Take great care when opening the top of the lubricator to ensure there is no pressure in the line by checking that the boiler stop valve is closed and the line is vented by having the engine control valve in a full ahead or astern position.

.jpg)

Introduction

I think above all else that it is the engine in a steam plant that really gives it a degree of fascination and attraction which an electric power plant can never hope to match. It is so difficult to define just what the attraction is, but a major part has to be the fact that you can see it all moving, as well as knowing that you have a perfect miniature reciprocating engine, including pistons, crankshafts and connecting rods all spinning around in your model. When I was at college in Liverpool we had an old steam reciprocating tug engine that we connected up to a painfully inadequate steam generator, but it was enough to turn it over. The sheer delight of just watching this engine going around will always remain with me as one of my favourite moments of my training and trying to lubricate the cups in the open crankcase just gave us all such a buzz.

Once again the first consideration with your engine is what it has to do and hence can you get what is needed into your model. Most manufacturers will stipulate a displacement that the engine will propel or a propeller size as a guidance, but you will still be left with choosing which of the many possible configurations suits what you want. Once again you have to define for yourself what you need the engine to do as regards the involvement at the pond side, reliability, ease of maintenance etc.

Configurations

To help you decide what you want to fit to your boat you first of all need to know a bit about the limitations of each type of engine available and hence what they can and cannot do so before we go any further have a look at Diagram One to help understand the difference between a single acting and a double acting cylinder.

Single cylinder, single acting oscillator

The simplest configuration has to be the single cylinder, single acting oscillator, Diagram Two. This engine has a cylinder that oscillates from side to side, which in turn opens and closes the supply and exhaust ports drilled into the cylinder and matching up with similar ports in the main frame. The piston and rod is solid, hence there is only a bearing at the crank throw, so the rotation of the crank moves the cylinder from side to side. It is this operation that makes the engine an oscillator type. The single acting part of the definition refers to the fact that steam is admitted to the top of the piston only. The bottom of the piston is open to atmosphere and there is only one power stroke per revolution, relying on the flywheel to rotate the engine through the exhaust stroke. This type of engine will not self start, so consequently it cannot be reversed. You will find engines such as this, Photo 1, in some of the simplest model boats of the type that are placed on the water with a fixed rudder and allowed to sail across to the other side where they can be retrieved.

The next stage up the evolutionary ladder is a twin, single acting oscillator. Two pistons arranged on a single crankshaft of either an in line, horizontally opposed or a Vee-configuration. Ports are arranged to both cylinders supplying and exhausting the steam which connect to common inlet and outlet pipes. Once again there is a possibility that it will not self start, but now there are two power strokes per revolution, giving a bit more useful output, but it still cannot be relied upon to be reversible.

Twin, double acting oscillator

Now to a considerably more common arrangement for modern model boat use and that is the twin, double acting oscillating engine, Photo 2. The significant difference here is that the lower part of the piston is sealed with a cover and a shaft seal, so now in addition, steam is admitted to the lower part of the piston, hence double acting. For a twin double acting oscillator you will have four power strokes per revolution, so the cylinders can be arranged to ensure there is always one on a power stroke. This engine is therefore self starting and hence reversible, so can be used in conjunction with a pressure regulating valve to control both speed and direction. Once again you will find these as either horizontally opposed, in line or Vee-engines with the Vee being the most compact in a longitudinal direction and the in line version being narrower and hence better suited to a finer stern arrangement in a model.

One of the biggest concerns with an oscillator is the fact that you are transferring steam to the cylinder through ports machined into two sliding faces. There is always going to be a possibility of steam leaking from these faces if they should become worn or if they are not sufficiently lubricated. Oscillators are also limited as regards performance adjustments, as the ports are not moveable and there has to be a degree of separation between the ports, so there is a dead band where steam is neither being supplied nor exhausted. The steam must also be admitted for the entire length of the piston travel and exhausted for the entire travel in the opposite direction, which does not give the best performance characteristics. This makes them slightly heavier on steam use, but nevertheless robust, simple, reliable, compact and relatively high revving.

Slide valve engine

The next major type of engine is the slide valve. With this type of engine, the cylinder is fixed and the piston is moved up and down with a more normal conrod as found in a petrol engine with a bearing at the top and the bottom. Steam is admitted to the top or the bottom of the piston by use of a valve that is housed in a chest attached to the cylinder. The steam entering the chest is directed by the valve that slides up and down within the chest and either supplies or exhausts the cylinder space and this valve is connected via another conrod to an eccentric on the crankshaft as in Diagram Three. The great advantages of these engines is that there is no loss of steam at the port faces as on an oscillator, and the steam inlet and outlet can be timed to give much better performance. To pay for that however you have the added complexity of two con rods per cylinder with their associated bearings. Once again a single cylinder double acting slide valve engine would not be considered self starting, because if the engine stopped at top dead centre or bottom dead centre it would have no starting torque. The other significant characteristic though of a slide valve engine is the fact that the valve can be infinitely adjusted to admit steam at just the right time in the cycle. This will usually be slightly before top dead centre so the valve is then set up to operate the engine in one direction only. Reversing a slide valve engine requires a complex linkage that adjusts the position of the slide valve relative to the crankshaft and once again makes the engine very complicated for the modeller and uses another channel and servo for the reversing linkage as in Photo 3.

Because of the requirement of the slide valve engine to have separate eccentrics on the crankshaft for each valve, creating a Vee-configuration would be very complex and this is certainly not a common configuration. In line twins are common though and horizontal twin configurations were very regularly used as factory engines throughout the industrial revolution years.

Other engine configurations include a piston valve arrangement which uses a piston rather than a slide valve to control the steam. There was a Vee-Four piston valve model engine produced by Maxwell Hemmens in the 1980s which is now a highly regarded and sought after piece of engineering, Photo 4.

A typical in line piston valve engine is shown in Photo 5, and there are a number of one off configurations created by imaginative minds with a desire to produce something unique.

Engine Fittings

Compared to a boiler the fittings on the engine are relatively few, however they are equally significant and need a degree of understanding to ensure reliable operation.

Control Valve: A number of oscillating engines will have the main control valve arranged as part of the engine and incorporate a rotating disc valve which slides over a ported distribution face. This type of valve allows operation of the engine via a single servo from a mid-stopped position to full ahead one way and full astern the other. These valves must be looked after and carefully lubricated to ensure smooth operation and all are fitted with an adjustable spring to vary the pressure on the rubbing faces. Too little pressure will lead to leaking of steam at the valve face and too much pressure will cause premature erosion of the face and once again, leakage. Another useful thing to remember with these valves is to always try to arrange the operating servo so that the servo arm is in the same plane as the valve operating arm. This will ensure that there is no component of the servo arm force trying to lift the valve off its face and help to keep the valve sealed. Valves on slide valve engines tend to be nothing more complex that a throttle valve, operated by a servo, to control the steam pressure, and hence speed, to the engine. Reversing will have to be done with another servo connected to the reversing mechanism.

Reversing Gear: Found only on a slide valve engine to enable the engine rotation to be reversed. There are a number of different types of mechanism, but none are simple and they usually require another servo to operate. They tend to be unreliable and difficult to set up to operate smoothly, so tend not to be found in too many boats. Most modellers tend to go for the less efficient, yet more reliable, oscillator engine. Another way around this is an arrangement that I am putting together for a launch which is to use a controllable pitch propeller. With this device the steam engine does not need to reverse, so the benefits of the slide valve engine can be enjoyed without having to worry about whether it will reverse just when you need it to.

Lubricator: There are mechanically operated lubricators available, but they do require engine power to operate and by far the most common found in marine models is the displacement lubricator. The importance of this device cannot be over estimated and the reliability and condition of your engine is entirely dependant on its operation. It simply consists of a vertical cylinder, full of lubricating oil, connected via a Tee-piece to the engine inlet. As steam passes the lubricator a small amount condenses and collects in the bottom of the cylinder. This displaces the lube oil, which then enters the inlet steam flow and passes through the engine with the steam, thereby oiling all the internal steam passages. If the lubricator is allowed to run dry, your engine will not be oiled and will very soon start to wear excessively on any running surface. You must also use proprietary steam oil in these lubricators with all the required properties to do the job to ensure reliable oiling of the engine. Each time the boat is brought into the bank it is well worth draining off the water from the bottom of the lubricator and topping up with fresh oil. Lubricators are fitted with a drain valve to enable this to be done and the water can be blown out under pressure from the boiler with the engine off. Take great care when opening the top of the lubricator to ensure there is no pressure in the line by checking that the boiler stop valve is closed and the line is vented by having the engine control valve in a full ahead or astern position.