This unique and very fast ferry, Photo 1, was built by Austal of Western Australia in 2003 and is currently operated by Fred Olsen Express. She can transport a maximum of 1290 passengers and 123 cars, plus has 450 metres of truck lane (which can also be used for cars) between the Canary Islands, Tenerife, La Gomera, El Hierro and La Palma, at speeds of up to 42 knots in most sea conditions.

She has a trimaran hull configuration, Photos 2 and 3, and is the second longest vessel in the world of this type. Benchijigua Express is 417ft long with a main central hull unit, in which are fitted four diesel/electric 8200kW power units in two engine rooms and their associated external water-jets. At the extreme edges of her 100ft beam are two smaller hulls which are about one third the length of the centre hull. The single vehicle and two passenger decks are configured to cover much of the three main user areas. Interestingly, Austal and General Dynamics based the hull design of the more recent US Navy Independence class Littoral Combat Ship on this Benchijigua Express design.

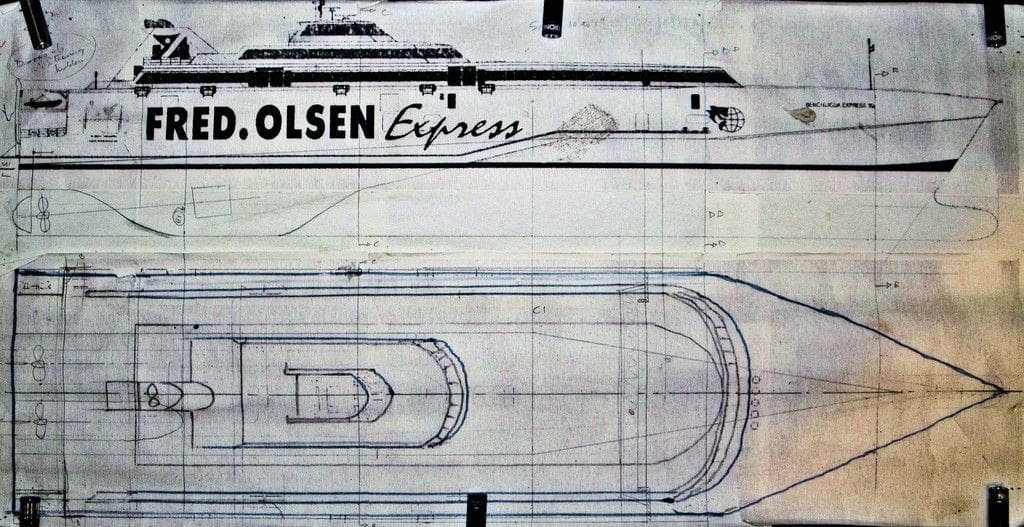

The model plan

Enjoy more Model Boats Magazine reading in the monthly magazine.

Click here to subscribe & save.

This is to a scale of 1:160, producing a model of 32 inches length, which is a handy size, but of course the beam is 7.5 inches. It is not a true 100% scale model, being propelled by conventional motor/propshaft drivetrains with the propellers running in Kort nozzles (ducts), but this was easier and less expensive than installing proprietary water-jet units.

A drawing is always essential when building a unique model and this was no exception. The model drawing, as in Photo 4, was prepared from a publicity brochure, so yes, as simple as just that! All that had to be done was to scan the brochure picture, enlarged to the desired size, print and then develop it to create a final drawing for what would hopefully be a practical and buoyant model. Some guesswork was involved and it was speedily realised that the hull construction needed to be lightweight.

Construction

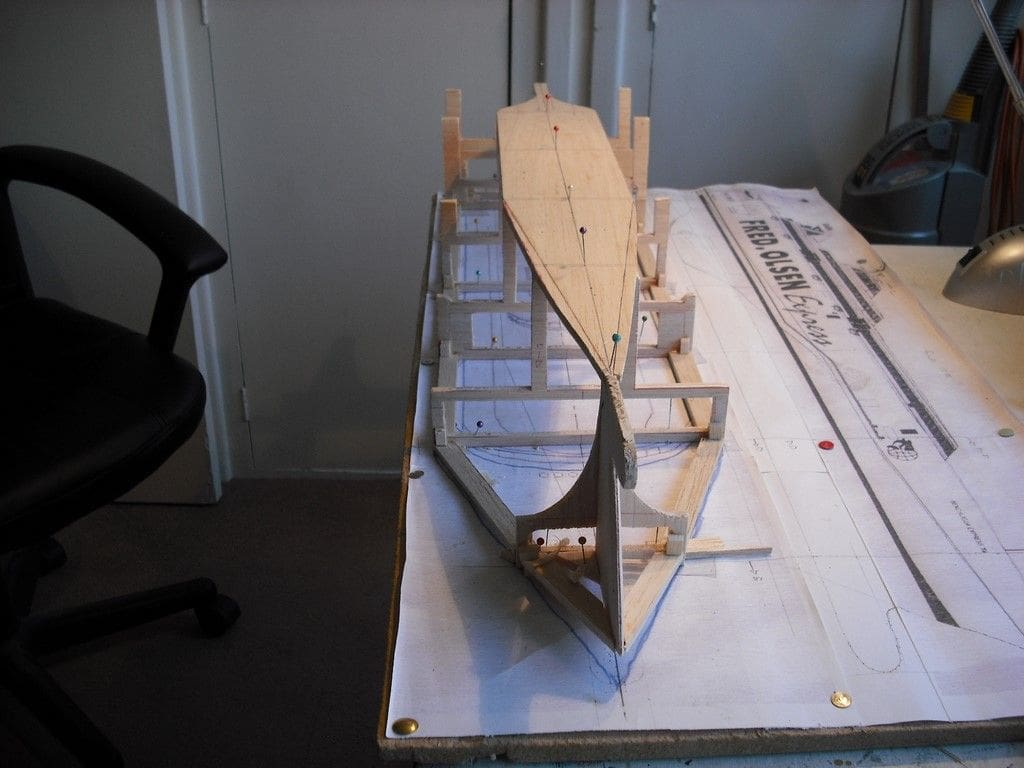

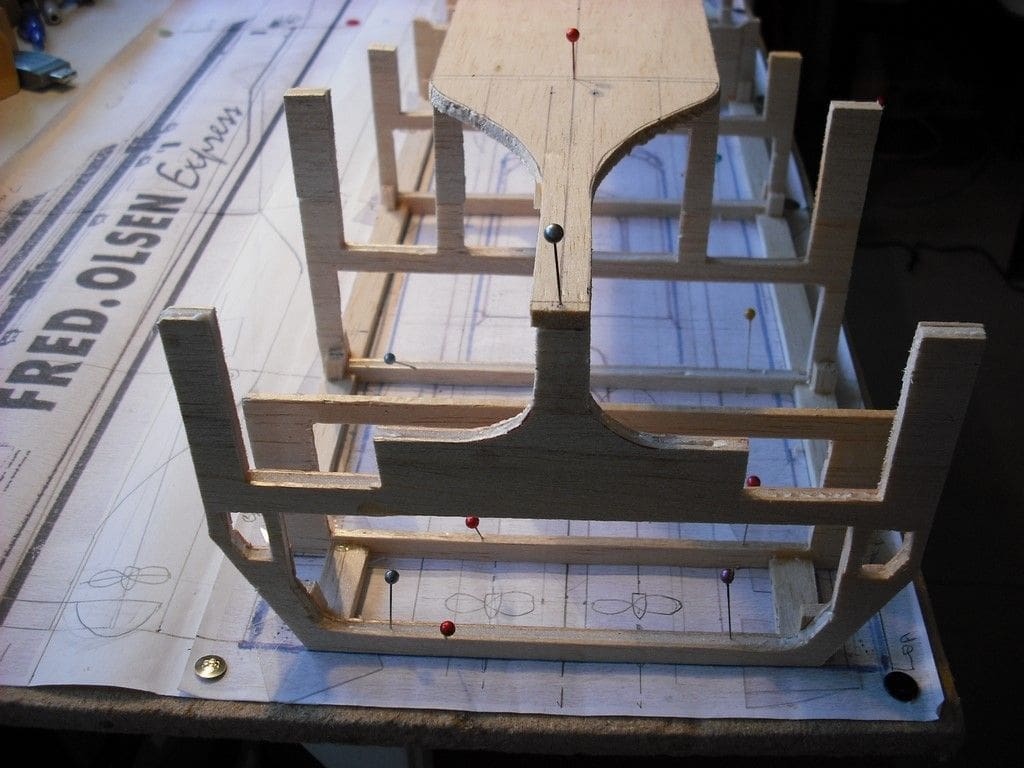

In summary, the model is built from balsa wood with the ribs and formers being of composites of thin balsa and polystyrene sheet, all glued together with PVA glue. Blocks of dense polystyrene were used to shape the complex areas at the fronts of the outer hulls and the central hull around the propellers.

Hull construction was therefore relatively simple, the basic framework being cut and assembled upside down as in Photos 5 and 6. Dense polystyrene blocks were shaped and glued into/between the wooden framework to create the complex shapes at the front ends of the side outer hulls and around the propshaft tunnels on the main central section. The flat and nearly flat areas were all skinned with 1/16 inch (1.5mm) balsa wood sheet, Photo 7, whilst 3/16 inch (4.5mm) sheet was used for the flat bottom section.

A few words about using polystyrene blocks in a hull won’t be amiss. You have to be careful, because some types of this expanded foam rapidly melt when certain adhesives or fillers are applied, so please do test on scrap piece before applying glue or a resin based filler. To circumvent this possible problem and to protect the shaped polystyrene blocks, they were coated in standard domestic Poly Filler, which was lightly sanded to a smooth finish and then given three coats of emulsion paint, lightly sanding after each coat. This could then be safely covered with lightweight glassfibre cloth and resin which tends to be cheaper than the epoxy resins much favoured by aeromodellers. The quality of the final hull finish is up to the builder, but in this case, because the hull had to be as lightweight as possible, the sheeted balsa sections were not treated to the fibreglass cloth and resin application. Okay, perhaps not perfectly smooth, but after two seasons of use, the hull is still sound. Photo 8 is of the bottom of the hull (a little bit grubby now!), but still perfectly serviceable after two years of use.

The upperworks are also from block and sheet balsa and cover a large opening in the deck which allows good access to the motors, speed controller, steering servo, receiver and battery, Photo 9. The red diecast London bus and lorry, which are about to scale and are at the stern on the vehicle deck, give an idea of the scale of the ferry. Obviously on the full-size vessel the vehicle deck occupies the whole hull.

Propulsion and steering

The full size craft has two large central water jet units with a smaller steerable unit on either side. These two smaller jets also provide the reverse thrust when needed. For simplicity, this model is driven by two 380 type brushed motors, Photo 10 connected to the propellers running in fixed Kort nozzle style ducts. Steering is by small rudders set in the flow from these nozzles, Photo 11. The propellers rotate in opposite directions and are coupled directly to the motors with no gearboxes. A 7.2 volt battery is located further forward, the radio is 2.4GHz, and a single 15 amp Mtroniks esc provides the necessary control for the motors. The rudders are connected to the rudder servo output arm by a length of flexible control wire restrained in a short length of copper tubing to turn the motion through 90 degrees.

In the light of operational experience, there were some further adjustments made, including enlarging the port rudder as in Photo 12.

Finishing off

As you can see from Photo 13, the superstructure is very simple and is of block and strip balsa wood. The logos were computer generated by using ‘screen grabs’ and scans from the promotional brochure, and then printed on to a clear special self adhesive film. The ‘black’ windows are just cut from standard ‘stick-a-trim’ type of self-adhesive trim that you can purchase from BECC Flags and others.

On the water and conclusion

The model has good speed and is stable, but tight-turns are not that wonderful, but there again you would expect that bearing in mind the flat-sided trimaran hull.

As a project, it was a challenge with a difference, but demonstrates that a workable model can be created from photographs and a basic drawing in a promotional brochure. I am happy with it as it does what I want and is a bit different from the usual model seen on a Sunday.

Good luck with your modelling – David Heaps