Engines and radio featured here at Collectors are almost invariably the end result of a long and difficult restoration process. For a change, I thought that readers might like to see a collectable classic (and the E.D. engine featured this time is certainly that), in exactly as found (af is antique trade shorthand for buyer beware and implies damage, restoration, or in some way, less than perfect order), condition just as it arrived at my door back on a lovely April day in 2005 almost exactly two years before this is due for publication.

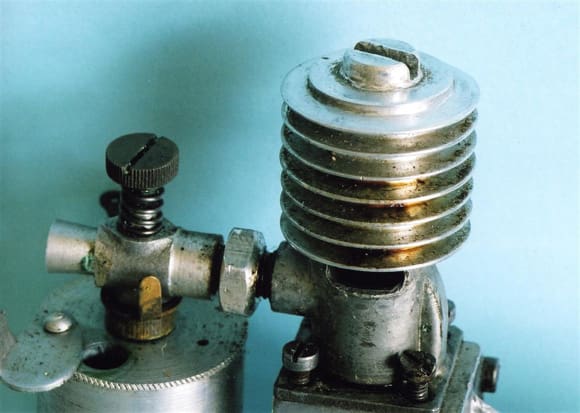

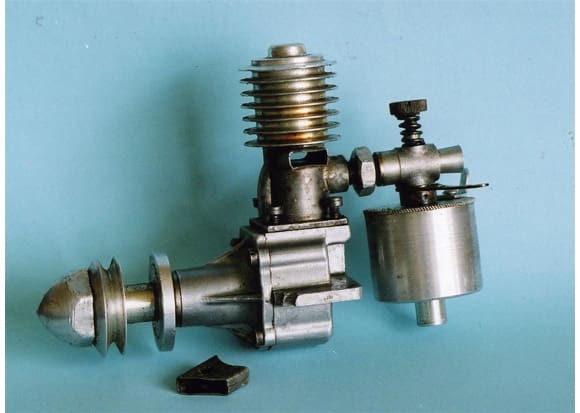

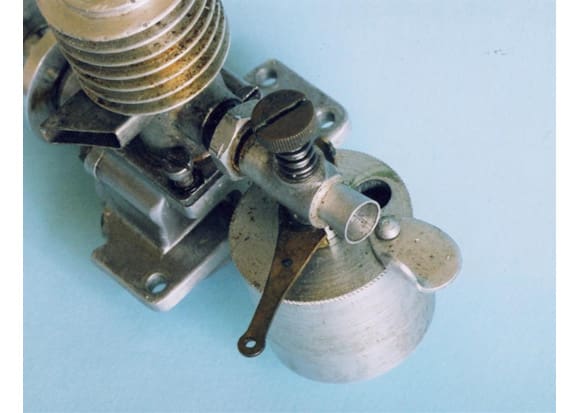

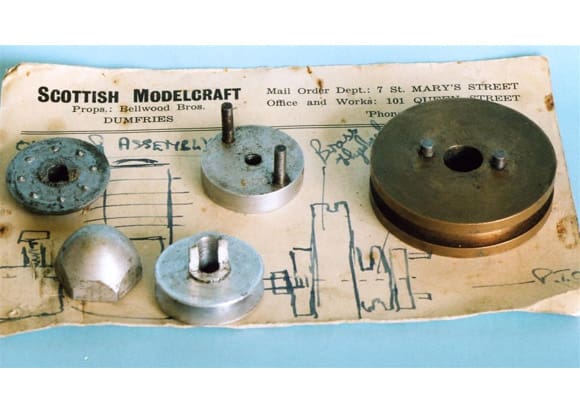

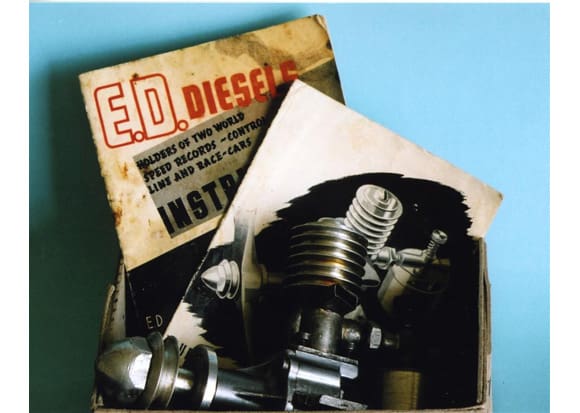

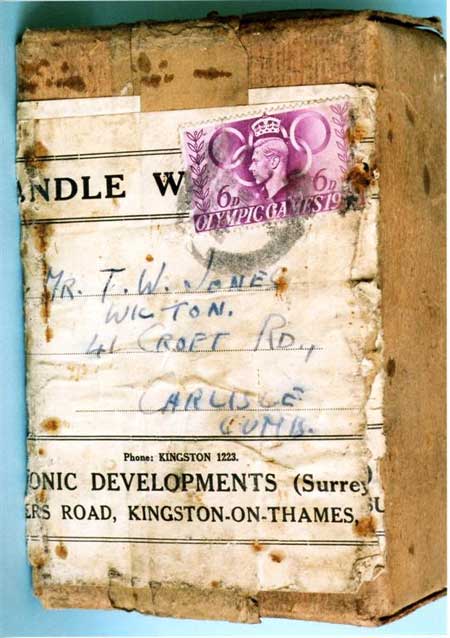

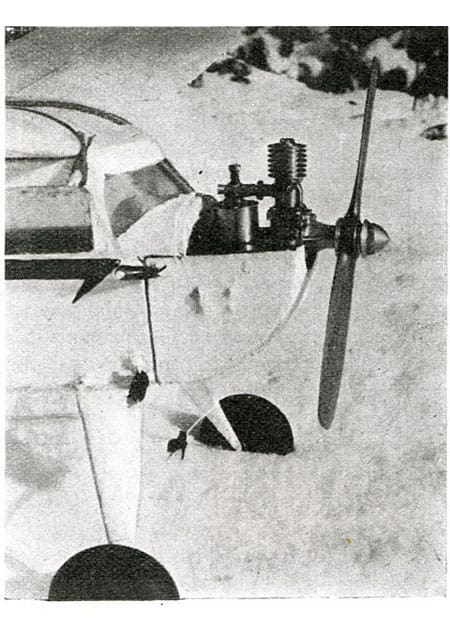

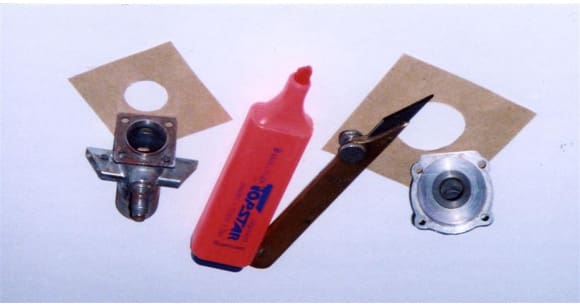

Pic 1: My close-up of the most unusual compression adjuster in E.D. Ltd.s pioneering early model diesel. Also seen is the failed soft solder joint where the snapped off exhaust stub comes from and the fuel filler praised by CE Bowden in his early book (see text). Pic 2: Bill Jones example of the E.D. Mk:Il (2cc) model diesel c1947/8 exactly as found back in April 2005. Sundry problems include detached exhaust stub, seized piston / liner and snapped main casting. All pretty much par for the course when you start buying old engines. Pic 3: Another close-up, this time of the alloy fuel tank complete with venturi, serrated needle-valve and spring and the cut off lever. The latter would have been activated by a clockwork timer in free flight model aircraft. Pic 4: Here are all the parts purchased by our reader for a marine conversion of his little engine, presumably bought from the Scots outlet on the postcard – flywheel, pulley and the male half of the coupling. Note the absence of a cooling jacket. At first, makers assumed air cooling would suffice in boats – an incorrect assumption as it turned out. Pic 5: Bills carefully kept old engine, complete with its original instruction booklets and its box.

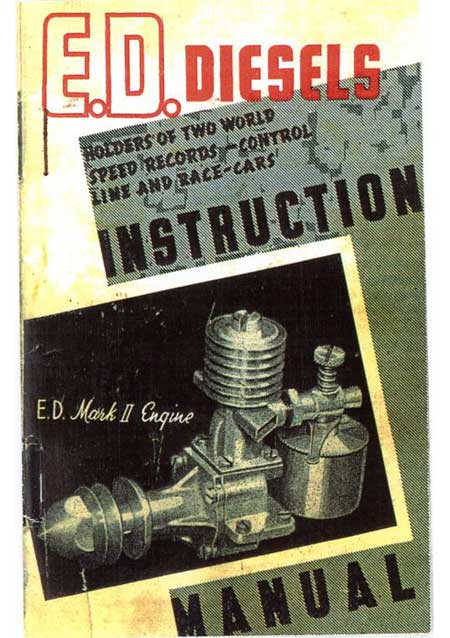

Although E.D. diesels were always factory made in large numbers they are nonetheless attractive to collectors, the very early models especially so. I think this is probably straightforward nostalgia at work for the truth surely is that many more of us could afford to fit an E.D., Mills, Frog, or Davies Charlton in our boat than could reach for a posh ETA, Oliver, Taplin, or Gannet or for an expensive imported glowplug engine. Hence, we remember them warmly. Another reason is that, even over a thirty year span, there were not so many different models that a complete set of E.D. engines is an unattainable objective. Just imagine aiming for a similar collection of 0.049 American glowplug engines or even every Cox engine made (and some people do try to do just that).

Enjoy more Model Boats Magazine reading in the monthly magazine.

Click here to subscribe & save.

The Very First ED Diesel Range

Starting just after World War II Electronic Developments (Surrey), Ltd., whose prime purpose (successfully achieved), was the design and manufacture of the first wave of British electronic radio control systems for model use, bought to the UK model market (such as it was just post-war), an initial range of just four miniature compression ignition engines known (not altogether accurately), as diesels. Advertised initially only as Mk:I / Mk:II / Competition Special and Mk:III and of 1, 2, 2, and 2.49cc capacity respectively they were priced between two pounds, five shillings for the smallest to just over four pounds for the larger – all prices in an era with purchase tax at around 30%. During the E.D. companys golden era in both radio and engine manufacture throughout the 1950s their diesel range was designed for company owner Jack Ballard by the talented hydroplane racer Basil Miles. but who designed this first foursome is unknown to me.

Of the first four engines the three smallest came to sell well – two of them really well. The smallest – the 1cc Mk:I engine was later developed into the famous Bee and for quite a few years was undoubtedly the biggest selling miniature engine worldwide with E.D. proudly claiming sales of over 300,000 units.

Their 2cc Competition Special, on the strength of one or two speed records, also achieved good sales while the Mk:II (also 2cc), I feature this month was its junior partner rather. Judging from experience as a collector there are plenty of Comps still around and certainly, there are lots of Bees as one might expect and nice examples of either are not difficult to find. I have never seen a Mk:III / 2.49cc and it was not until the coming of Basil Miles superb twin ballrace equipped Racer that E.D. achieved supremacy in the mass produced 2.5cc diesel class. In both 1 and 2cc sizes even mint, unrun and boxed engines can pop up now and then but a decently minty Mk:II is not so easy to find and thus one may have to settle for something more like the nice but damaged example sent in for our pleasure by Carlisle based reader Bill Jones. This was bought by him back in 1948 (note the special Olympic Games / George VI stamp on his box), for an air-sea rescue launch (refer back to September 2005 Collectors Corner to admire this) he was building then. As to provenance, you cannot do better than an engine that has been owned since new by the same modeller.

With a Penny Slot!

On the down side, any keen model engine collector is going to be turned off by the particular damage seen on this example of an item known to modern collectors as The Penny Slot – its damaged cast mounting lug. There is nothing nastier in engine damage really – it looks ugly (especially at the front), and is bad news if you want to mount and run it. Such extreme damage is most often caused by a long ago crash in a model aircraft but in this case Bill says it was caused by mounting in a vice a really heinous crime in most books! Normally, I am no different to most and would tend to exercise some patience by declining such an engine, preferring to wait until a better one came along but, for some reason (perhaps it was that stamp!), I fancied it. There is other damage too for an exhaust stub had broken off (just failed solder to be fair), and – worst of all – the engine was seized solid. The owner had had a go at freeing it up himself as you can see from all the loosened screws but without success. At the outset I took the job on from Bill only on the clear understanding that it could be a fair while and without guarantee of success. In the event I was too cautious and had it in bits within a week with the only new parts needed being a replacement gasket set.

And the Penny Slot name? I suppose its fairly obvious that the cylinder head lacks the model diesels normal (normal post about 1950 anyway) tommy bar compression adjuster, and has a coin sized slot milled across the cylinder head instead, but the reasons why this is so are obscure unless you are knowledgeable about the history and design development of the model diesel engine.

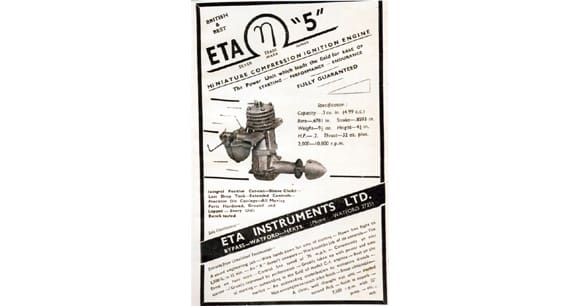

When the first few designs (the Swiss Dyno et al), emerged from Europe just before the 39-45 war the need for compression ratio adjustment via a contra-piston was dismissed by many designers, and some famous engines of the pre-and post-war period did without. I illustrate here the 5cc Owat as one example of a fixed compression engine though the French Morin is the most famous of the genre. The first model ETA – also of 5cc – is my chosen early example of the other approach, having the now familiar tommy bar adjuster albeit with a limit pin in the head, allowing only a single turn range of adjustment (as in the Mills engine – perhaps the most successful and popular of all the first wave of model diesels). Both Ads are taken from an early book in my collection – Diesel Model Engines by Lt. Colonel CE Bowden published by Percival Marshall in 1947 – like its companion volume Model Petrol Engines it is a useful book for a modern collector to own.

My guess is that, for their first 2cc diesel (this Mk:II), E.D. were hedging their bets in this then still raging design debate, and provided a method allowing now and then minor compression adjustment to take account of different fuel brews and temperatures. By the time they had further developed their 2cc engine into the famous Comp they had found (my bet), two things; (a) the need for adjustment was more frequent than they thought and, (b) trying to adjust the cylinder head with a coin behind an airscrew whizzing round at up to 8,000 rpm was distinctly dangerous! As far as Im aware the coin adjust idea was never used again or by anyone else and an example of this particular engine is therefore an especially interesting object to have in any collection of miniature diesels.

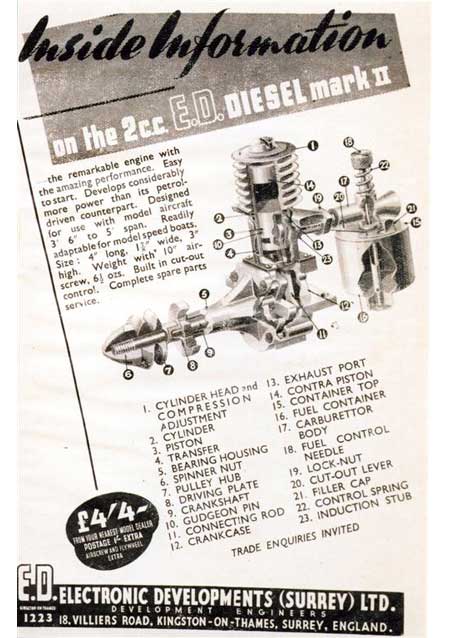

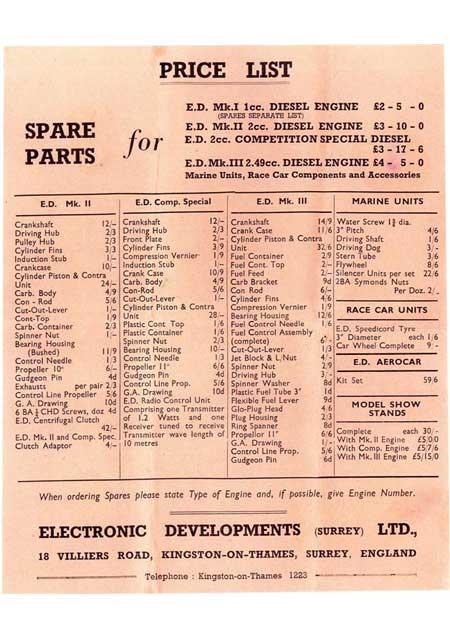

Pic 6: And talking of the box! – here is the stamped and postmarked boxtop dated 1948 and from E.D. Ltd at its very first address in Kingston-on-Thames. The stamp is of the George VI 1948 Olympic Games sixpenny postage stamp. Pic 7: This wonderfully clear Ad from E.D. c1947 tells you everything you could want to know about an E.D. or any other small diesel of the very early period for that matter. Pic 8: Precision built – Phenomenal performance – 1948 advertising for the British Industries Fair c. late 1940s. Pic 9: E.D. Ltd.s 1948 price list of spares and accessories for Mk:II Comp and Mk:III engines with marine items listed top right. This sort of thing is really useful for writers, especially if, like myself, its a bit before your time. Pic 10: A very pleasant image the cover of E.D.s instruction booklet. Pic 11: This picture is from Diesel Model Engines by Lt. Col. CE Bowden (Percival Marshall 1947); an invaluable little hardcover book to anyone interested in the very earliest model diesel engines. My chosen picture shows the ED Mk:II (2cc) in a Bowden model aircraft. Judging from that wheel it is either sitting in snow (47 was a tough winter so it could be just that), or on very lush carpet!

Tested by Bowden in 1947

Lets see what CE Bowden had to say about E.D. Ltd.s little motor back in 1947. The E.D. Mark II 2cc diesel is British and a very nice looking little engine weighing 6ozs. It is, sensibly, robustly built in the right places. The engine has large exhaust ports and a small induction venturi tube combined with an ample transfer passage which all help towards its sound performance. The cylinder head is adjustable for compression ratio but instead of having the more usual hand lever there is a slot cut in the head. A screwdriver or coin is used to turn the head. The engine is stopped by a simplified variation of the system on the German Eisfeldt diesel. This destroys the suction by admitting air. The example that I have runs extremely well on a 10in diameter propeller of low pitch and flies a model of 4ft 6ins span with elliptical wing shape. The needle valve is fitted with a safety stop to prevent damaged seatings which is a good point. The bore is 0.5in, the stroke 0.625in. As in the case of all good diesels the engine turns easily and yet has an excellently fitting piston and therefore good compression. The fuel tank has a really sensible sized filling orifice. (end quotes CEB).

The author illustrates the model he refers to in his review and I reproduce it here. Pre 1947, it is very typical of Bowden model aeroplane designs and a very handsome machine – more handsome still when the ellipse of the wings is seen. You can just see the rubber band wing retention common right through to the sixties and the knock-off nose retained by the same simple method. Bowdens review of the ED Mk:II was backed up in his book by a full page Ad taken by E.D. Ltd., also reproduced here. The E.D. drawing is so good and so well captioned that there is little to add – the early model compression ignition engine is displayed and explained in near X-Ray clarity.

CE Bowden refers to his liking for the aluminium tank on this engine and the one seen on Bills example is in fact the control-line version – one of two offered and the larger of the two. The Mk:II, being a simple sideport induction two stroke like the contemporary Mills, it was a simple matter to invert the tank for inverted engine mounting in a model aircraft too, and E.D. emphasised this as a plus in their advertising. Later, as on their Comp, the firm bought in attractive see through coloured plastic tanks that, while useful at the time, tend not to last whereas this strong alloy tank will last for ever.

Talking of fuel for this vintage engine the standard E.D. brew was, right from the start until well into the 1970s, one third each of ether, Castrol, and paraffin for starting, lubrication and fuel respectively. Ideal running rpm is about 6-7,000 on a 9 or 10in diameter 4in pitch wooden airscrew. It is of course no hotrod – more a reliable plodder like your author!

Precision Built / Phenomenal Performance

Our reader sent in documents with his old engine and these are just as interesting. I lead with the above headline (well, puff if you prefer!) This Ad, for a British Industries Fair stand, promotes the 2cc E.D. unit at 4 guineas plus 1/- post and is most interesting in that it reveals that the firm was still anxious to attract trade enquiries at that stage and were obviously still some way from being safely established as the market leader that they went on to become and stay; long after firms like Owat had faded. The pink price list shows that all spares were both available and fairly priced (con-rod 5/6d, gudgeon pin four pence!) and, as early as it was, E.D. had clearly recognised that there were sales outside of the flying field with kits and spares for both boat and car models.

The Penny Slot on pond and road

In a list of parts for marine use it was assumed the engine would remain air-cooled as there is no water-jacket offered amongst the flywheel, coupling, silencers and waterscrews all listed and priced. As far as I am aware no other manufacturer c1947/8 had made such generous provision for model boat customers who were not lathe and mill toting model engineers (an assumption oft made then and which stuck for quite a while) – a situation that gave people like Max Coote of Ripmax an ideal opening to arrange for design and manufacture of water jacket and flywheel sets for many other model engine brands (Mills being just one), who simply could not be bothered to make them available themselves. RMA and Max did well out of such idleness it must be said and well deserved it was too. Another sheet gave a detailed spec for the engine.

Pic 12: The beginning to restoration on any old engine. The completely seized E.D. Mk:II engine has been soaked in cellulose thinners overnight and then heat has been applied where necessary to crack the glue like varnish and achieve a successful strip. As you can see, theres not that much to a small diesel but the secret is in the mass production engineering tolerances and fits the makers must achieve for an easy starting and reliable product. Pics 13 & 14: Competitors on the early diesel scene (both from Ads in CE Bowdens 1947 book – see text), were the fixed compression Owat and variable compression ETA. ETA went on to build a fine reputation in top quality 2.5 and 5cc model racing engines, diesel and glow respectively. The fixed compression designs favoured by Owat proved a dead end. Pic 15 & 16: Two close-ups – (top) the Control Line fuel tank seen against a modern five pence coin and (bottom), the engravings of serial number (G988/7), and Made In England. The tank is a proper bit of engineering in its own right but E.D. soon found ways of cheapening it using early plastics! Pic 17: My very first step in restoring this very early British diesel – marking out and cutting blanks for two new paper gaskets (front housing to crankcase left and cylinder to crankcase right). 60 year old ones are virtually never reusable as they disintegrate when the engine is stripped. An old brown envelope is the material and a modelling knife and marker the only tools required! To mark and cut the inner circles accurately you just run the marker around the edge of the rim, place the part flat onto the paper and cut around the coloured line. Results as you see. The engine is now assembled with the new gasket and finally, the outside edges are cut round with a sharp blade. This is an old established amateur method. A professional would make a die and stamp them out.

Starting to get it running again

It being my intention to present the engine exactly as it came in I will not discuss the restoration of small vintage diesels in any detail here but I did have a quick look at Mr. Jones. E.D. in late April of 2005 and found that every single metal to metal surface (crankshaft in bearing, piston and contra piston in cylinder, cylinder head to cylinder), was seized solid. My usual overnight soak in cellulose thinners followed by a bit of localised gentle heat plus a bench drill adapted as a press soon freed the crankshaft from its plain bearing, but the piston(s) and cylinder head were impossible to shift and, being busy on bigger things than little engines, I laid the job aside.

But a few days later with the weather not up to outdoor work I felt a bit more in the mood and I stripped it completely using rather more heat and much more force (bf&bi as engineers say!) but applied with (I will say), some knowledge and feel born of doing lots of others. The cause of seizure was undoubtedly what Americans call varnish – a good term implying that old castor oil left in the bore for many idle years has hardened into a yellow coloured glue that does look exactly like yellowed yacht varnish.

Before sending this feature off to our Editor I just had time to squeeze in one picture of Bills good old engine stripped to its component parts as proof that (in May 2005), I was on my way towards achieving a successful running order restoration in which the main delay will be jigging and cutting the two paper gaskets required. Doesnt sound much does it but it could take me a year or two owing to all those other jobs we practical folk seem to attract!

I hope it is obvious from this brief preamble that fixing these things is often not as easy as it may appear and I always caution prospective new collectors against buying seized up engines if they have no real workshop facilities or engineering experience. Our readers old E.D. is a good example of a less than easy restoration project. In particular, being soft soldered (inlet pipe and manifold, exhaust stubs and cylinder to baseplate joint) throughout just like my favourite Taplin-Twin (and guess who Colonel Taps Taplin emulated when designing his first twin!), one cannot simply heat it all up with abandon but I think well leave things there for now.

And how much / next month!

A really mint Mk:II engine in a nice original box with instructions etc,. (Bills has a few damages, was seized and had only half its original box), might rate about £80-90 from a dealer (2005 prices), and a bit less privately. In the condition seen here one is surely worth half that but only if you are confident enough to take a risk on a seized and damaged diesel. My monster thanks to Bill Jones for allowing me to feature his treasured little memento of no doubt very happy times past in my column. Do take the time to look back through these columns for the lovely ASR launch he bought it for – together they are so typical of the late 40s model power boat scene.

Well, I must say it seems really odd to be sitting in my little home office during late April 2005 thinking ahead to a second retirement with the series planned to end in mid 2007 but that is how Ive always worked – no nasty deadlines for me. Next months content is still a bit uncertain as this column moves towards its close but I expect Ill find you something old and interesting. So may I hope to see you all again then – here in Model Boats. I do hope so.