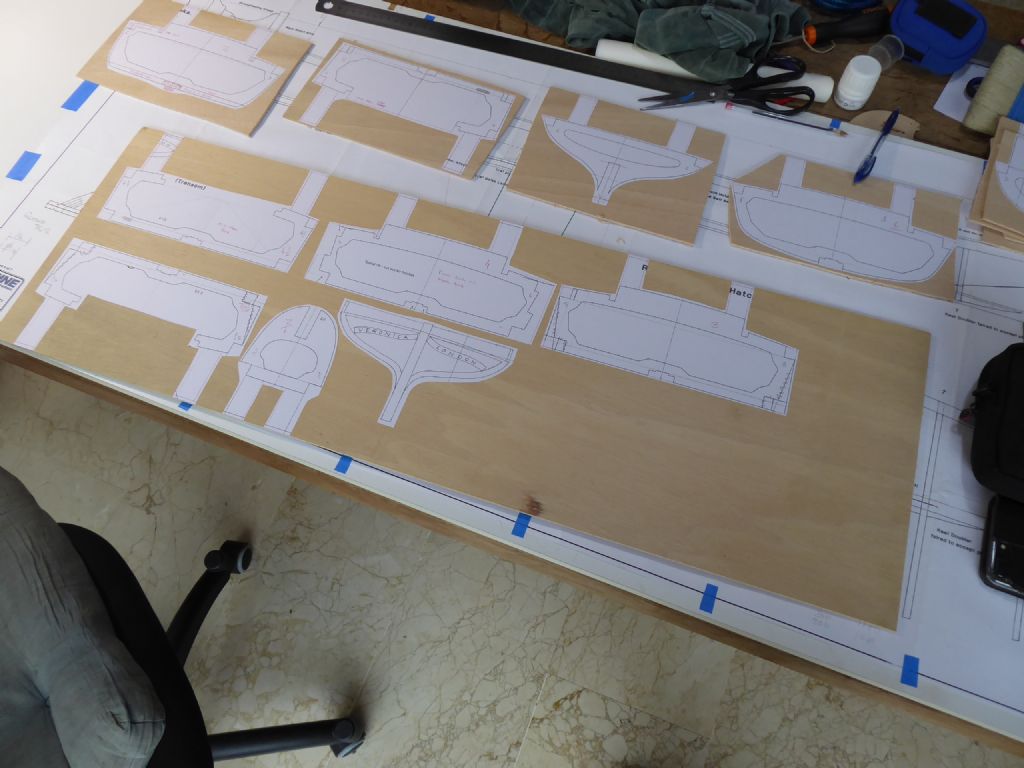

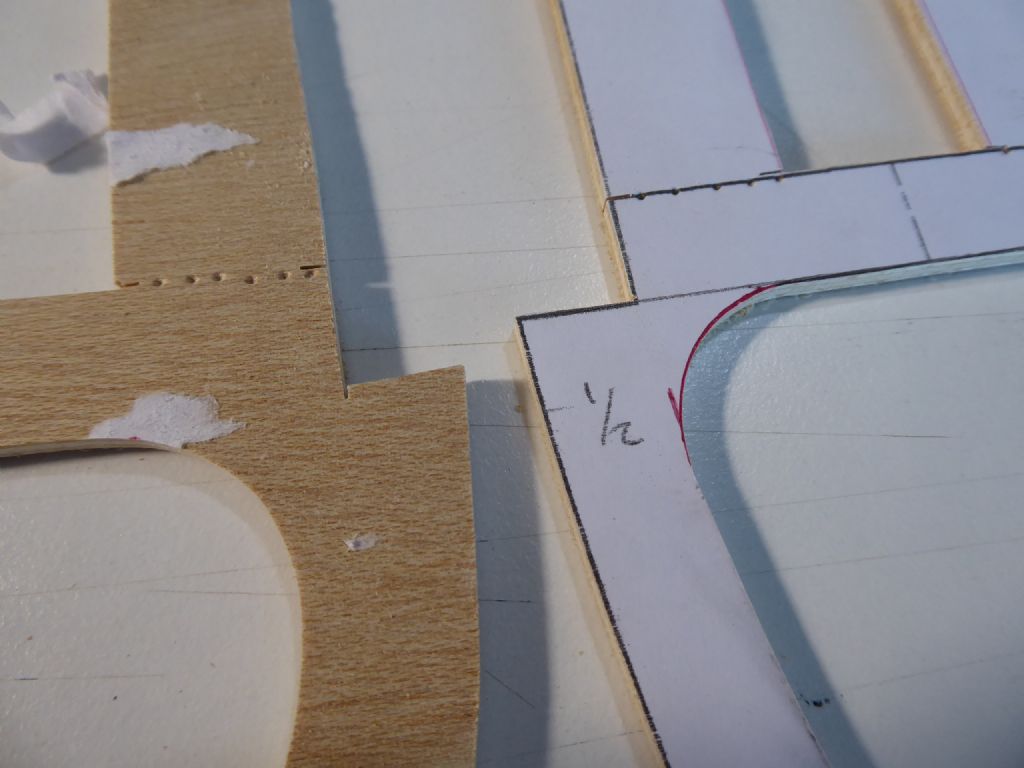

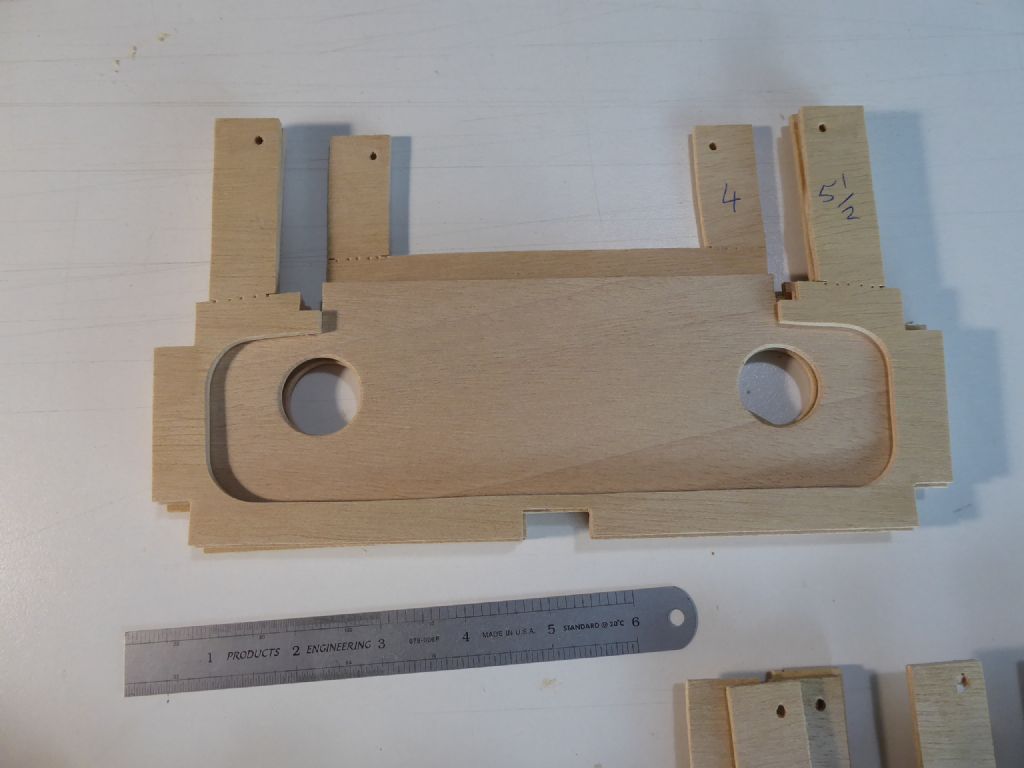

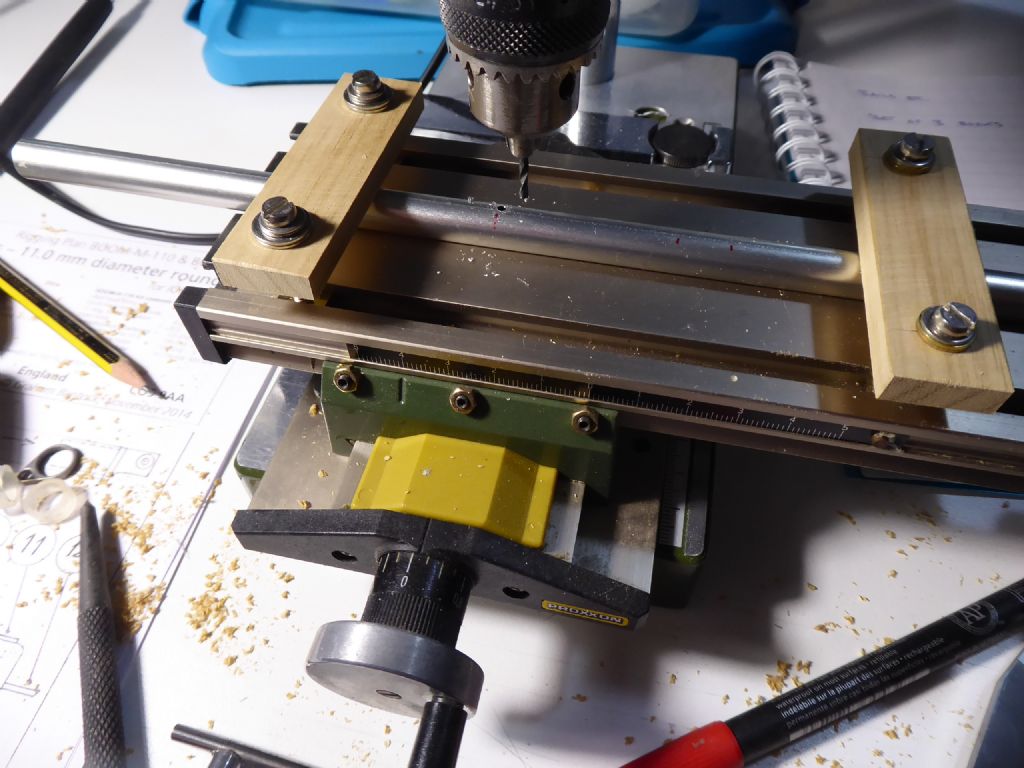

Been doing a bit of barge building but first of all a good look at the drawings and there are lots of them with some great detail. There has been lots of barge stuff here so this is not a complete blog but just highlights some of the changes I made and some of the tricky bits.

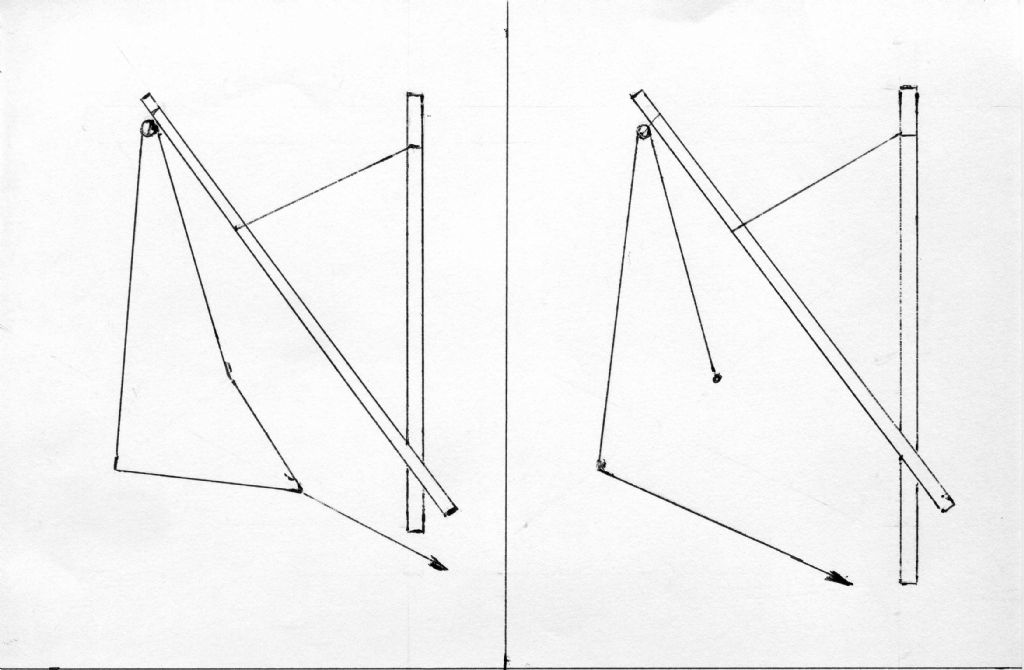

First up I wanted to replicate the keel system that I used for Galileo including the lead bulb because I already have the mould. The lead however is at the light end of the range compared with the notes on the drawing which is OK as long as the draft is a bit deeper. I sail in the harbour so a bit of extra draft is not a problem. The keel options on the drawing are a bit of a fat section for my liking but with the single bolt system for fixing I can see why.

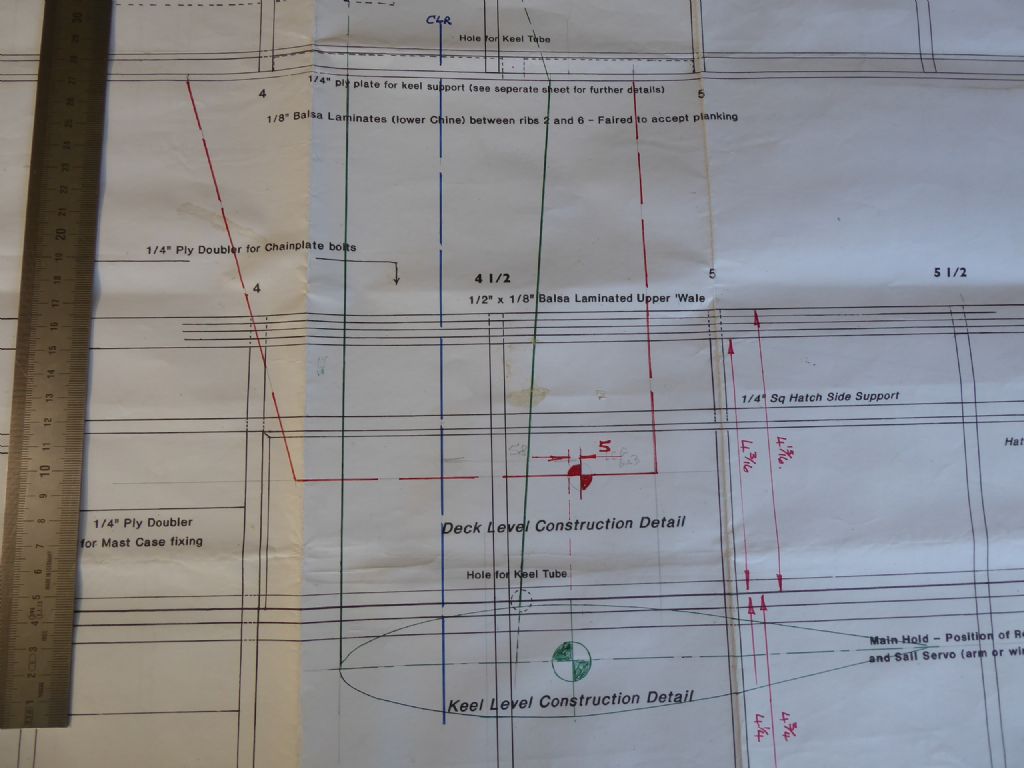

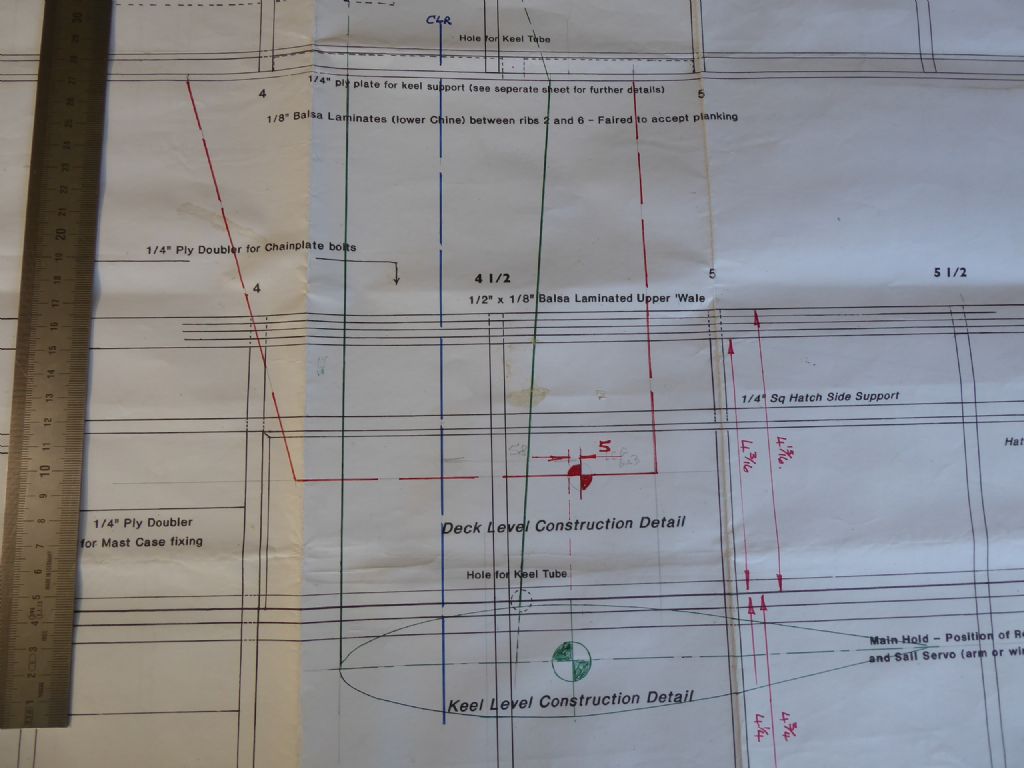

The first job was to draw the existing fin and bulb on the profile, the red lines and calculate the Centre of Lateral Resistance (CLR). This is quite easy with simple geometry and is a line passing through the centroid. I have marked this line in blue. Obviously my new keel profile should have the same CLR or I will be changing the characteristics of the designed balance. For the purpose of this exercise I have ignored the CLR of the bulb on the basis that the difference should be marginal.

The new fin is drawn in green and is much higher aspect ratio and will bring the draft to approximately 300mm.

The high aspect ratio will be more susceptible to stalling if I get stuck in irons but overall it will be significantly more efficient and has about 70% less wetted surface area than the original which may be cutting the side area a bit fine but we will see.

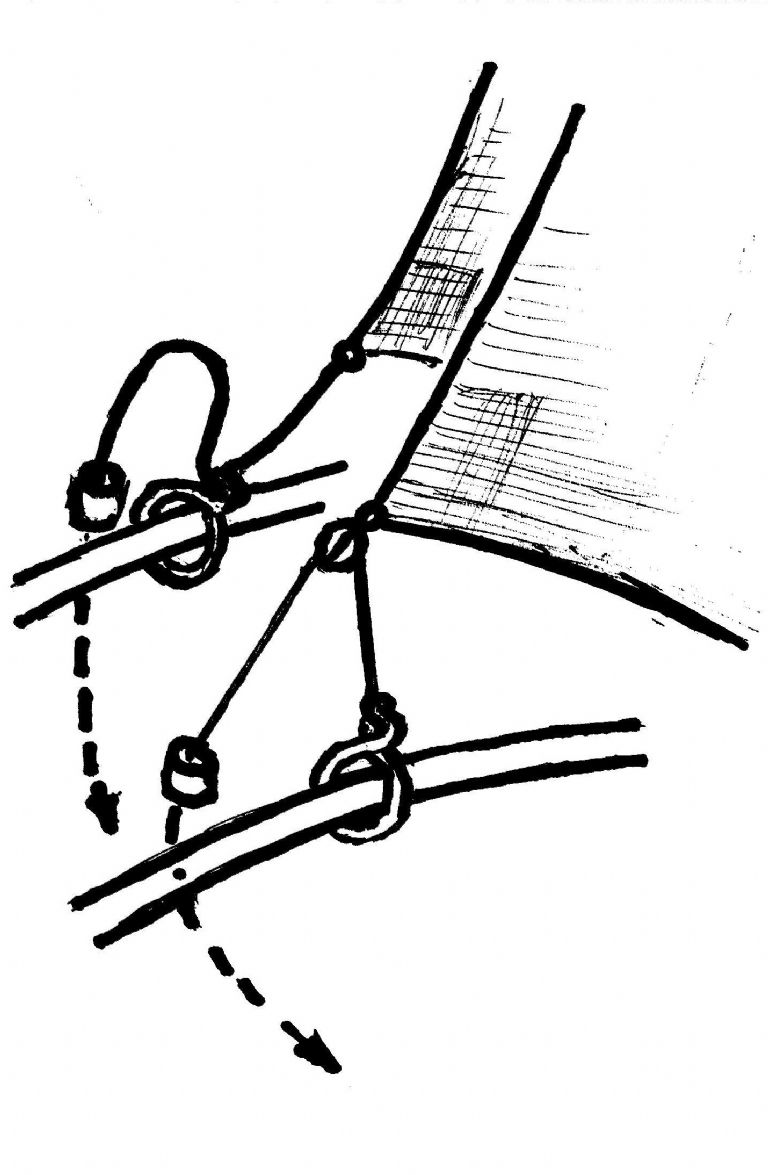

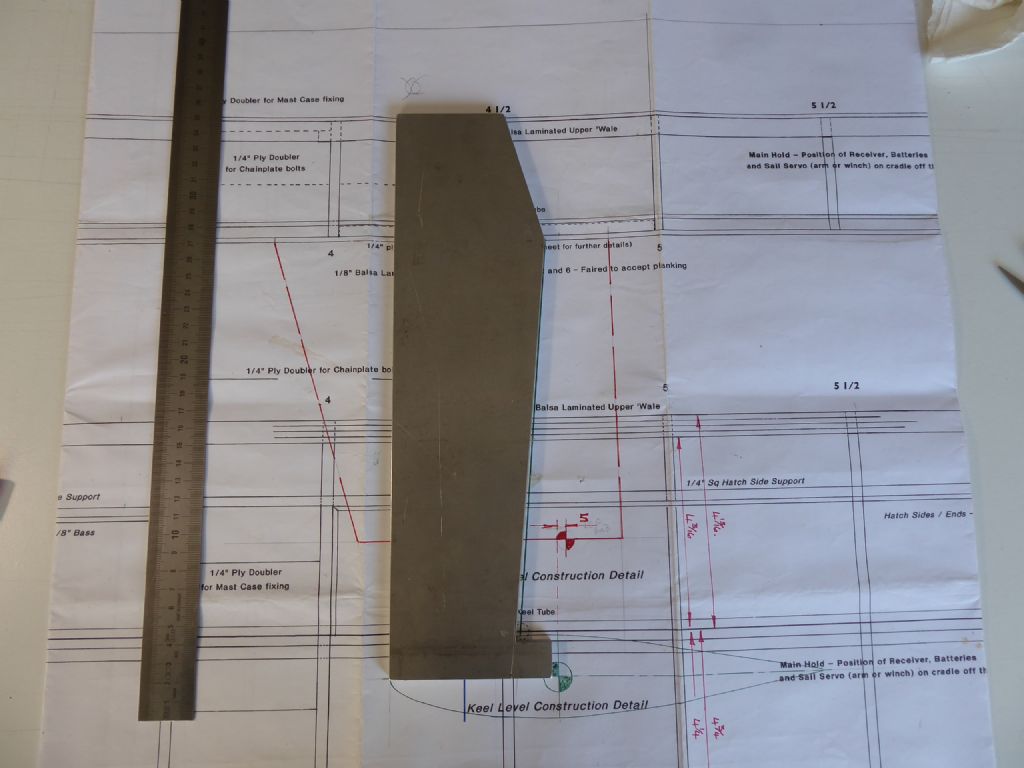

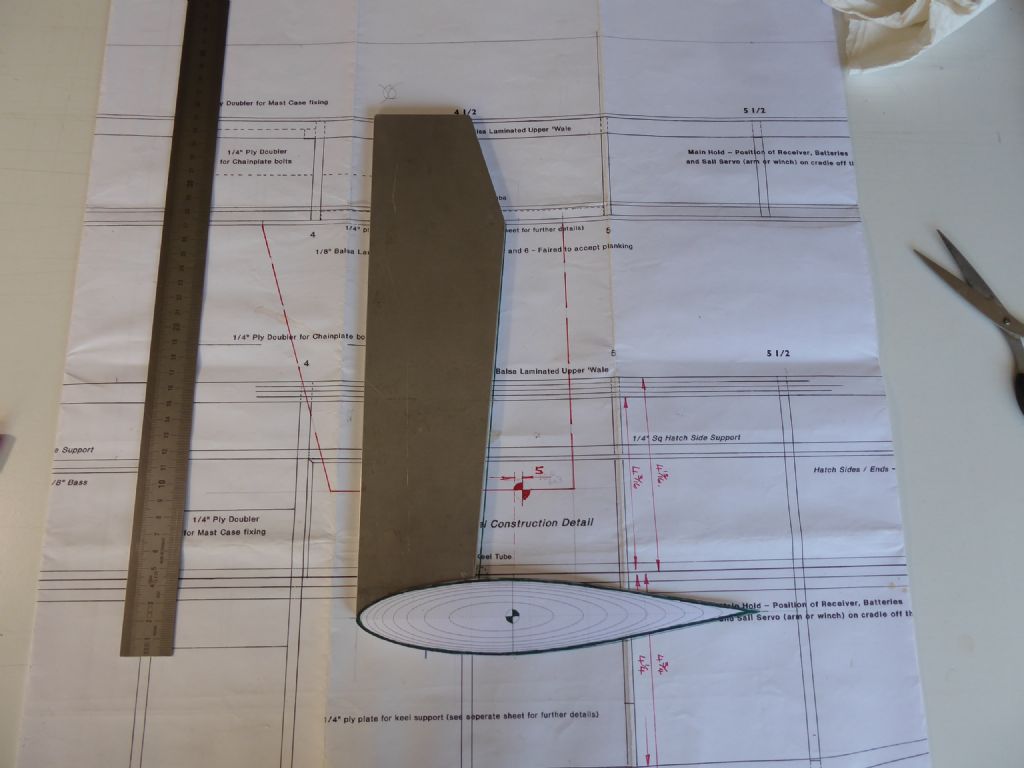

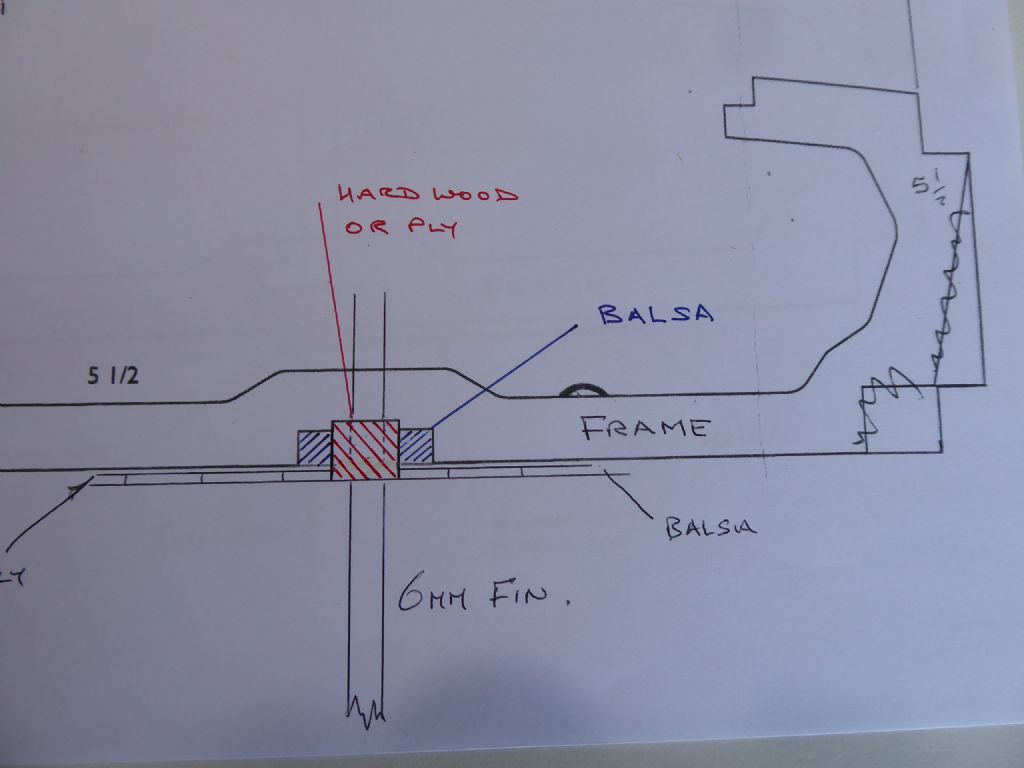

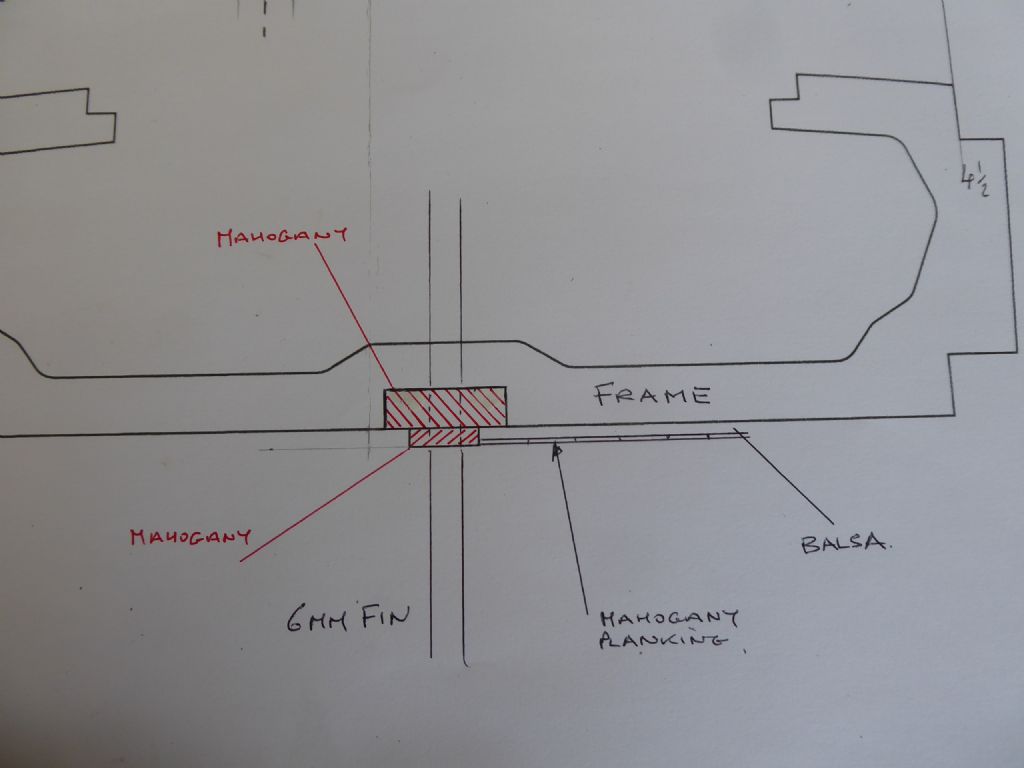

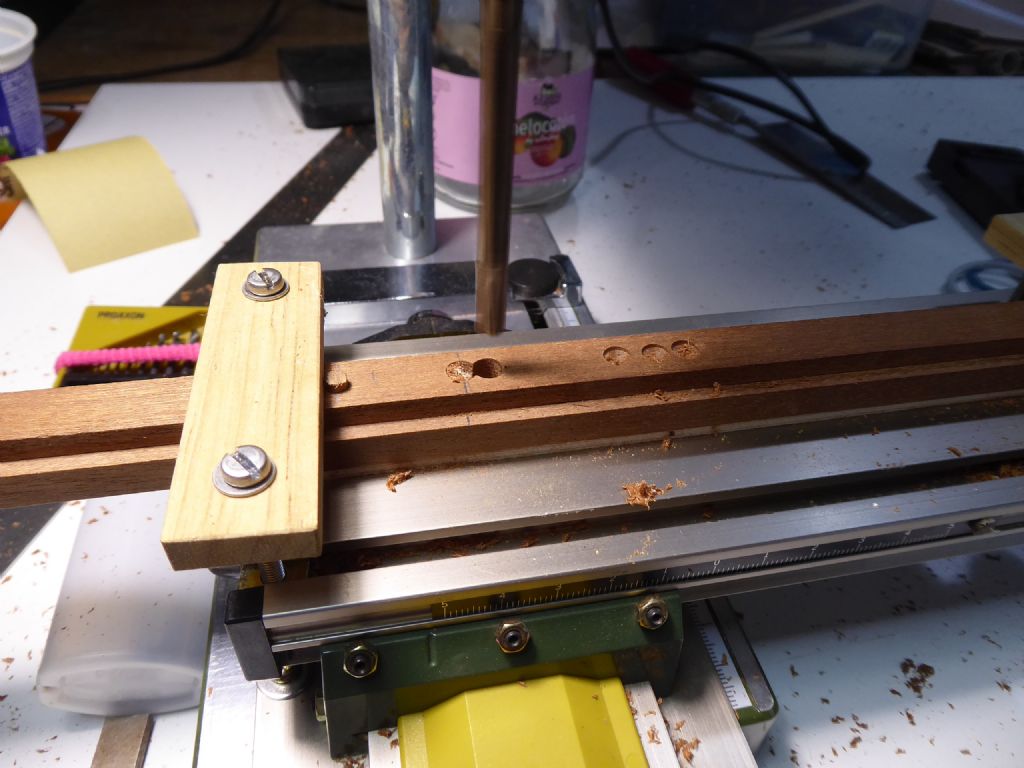

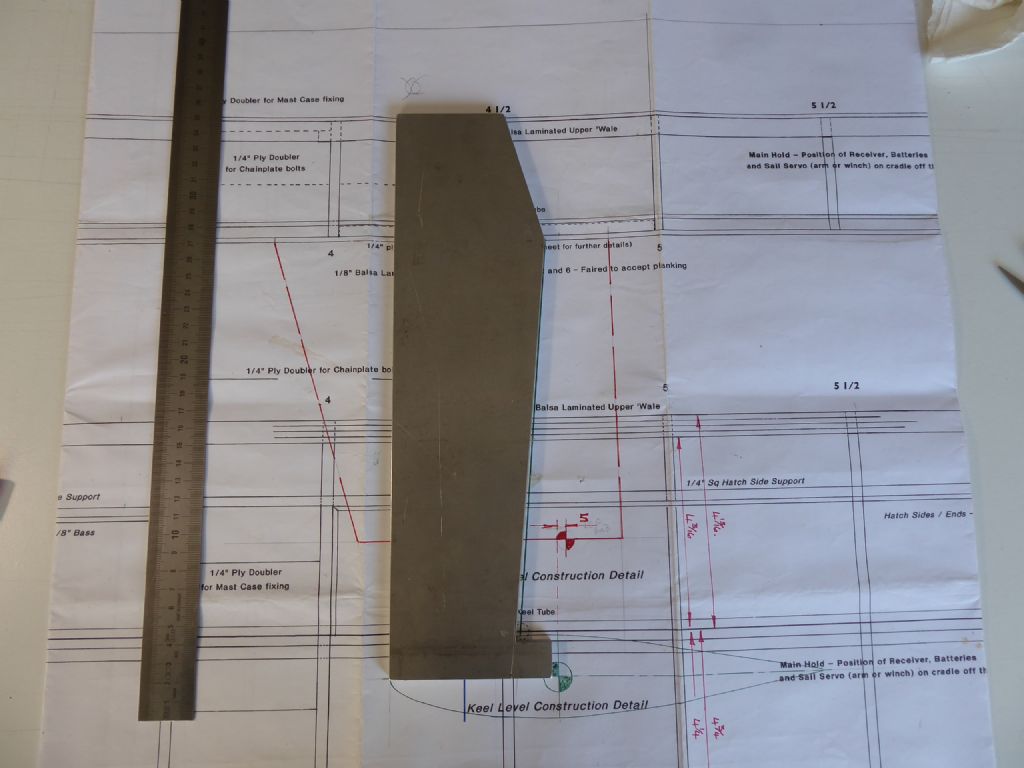

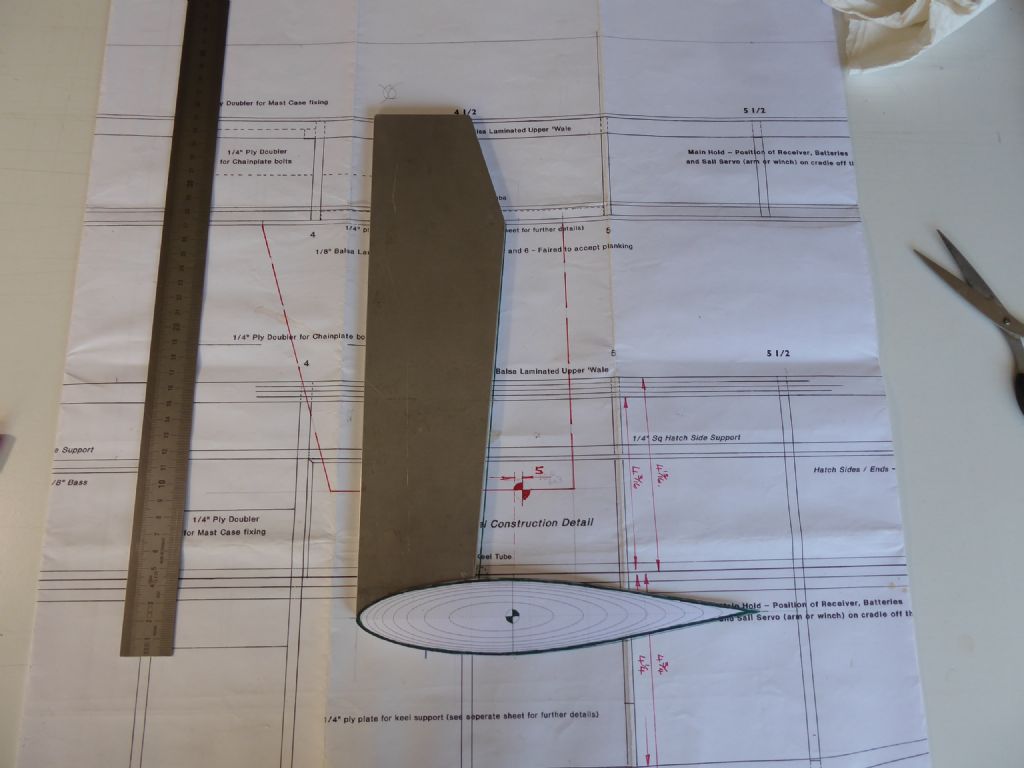

This is the fin blank made from high tensile aluminium at 6mm thick. When faired it will be about 8mm and the tapered section fits into a slot in the hull. The taper is a non-locking angle but when the retaining bolt is tight, the keel will be well supported and very secure.

I have now superimposed a template of Galileo's bulb. With the front of the bulb lined up with the leading edge of the new fin there is only a 5mm shift of centre of gravity of the ballast which given the length of the hull and the displacement is insignificant. I was expecting this to be close but 5mm was a very happy accident.

Tim R

Richard Simpson.

Richard Simpson.