I have continued to work on the right hand gantry support over the last couple of days. There is a lifebelt fixed to the inside face so I decided to have a go at a batch of these as I will need 4 in total. I used some good quality 5 mm ply and cut some 30 mm diameter discs using my scroll saw and disck sander. I then drilled a 4 mm pilot hole through the middle and fixed in a 4 mm screw and captive nut so that I could mount the disc in my pillar drill. ( I dont have a lathe, hence I have to improvise). Using a sanding block I then sanded the outside edge to a smooth radius. The next step was to drill a hole through the middle, using a 16 mm flat wood cutting drill, being careful to avoid my fingers while holding the disc on the pillar drill. I then radiused the inside edge using a Dremel sanding drum and finally sandpaper wrapped around a piece of dowel. The central hole needs to end up about 18 mm diameter to be the correct scale size. The picture below illustrates these 4 stages.

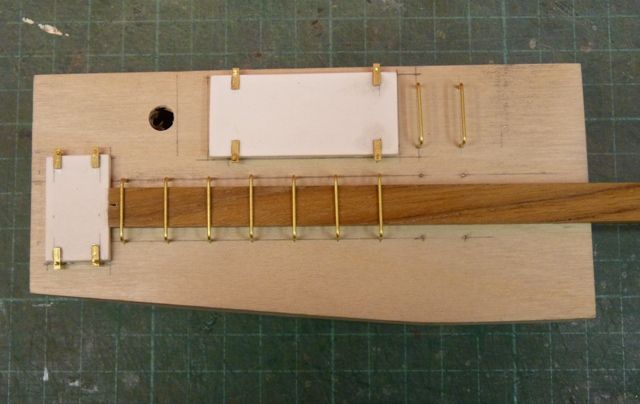

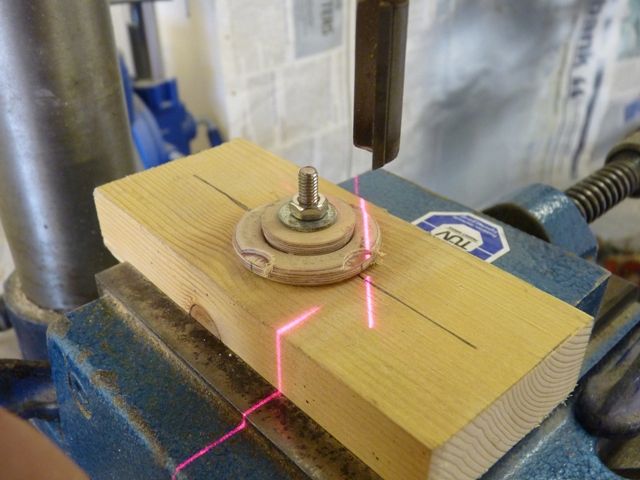

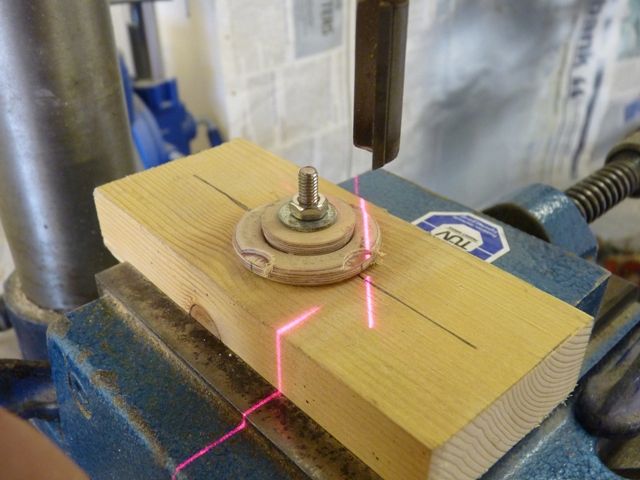

I then made another ply disc about 20 mm diameter but with the outside edge tapered down to about 17 mm, a bit like a plug. This was made the same way as the first two stages above and is used as a collet to hold the lifebelt discs down for the next stage. I cut a short length of timber, marked a centreline and drilled a hole though as shown below. Each of the lifebelts was marked on the edge into 4 equidistant quadrants. The pencil line was lined up with the centreline on the timber block to allow the lifebelt to be rotaed round in 90 degree steps. I used a router cutter mounted in my pillar drill to cut the 4 small recesses round the edge of the belt. The fixture for holding the lifebelt was left clamped to the pillar drill table while I cut the recesses in all the lifebelts.

I then removed the belt from the fixture and drilled two small holes through each recess for the rope to be recured. I then turned the belt over on the fixture and using each pair of holes as a guide, drilled the recesses on the other side. FInally I could thread a bit of cord through the holes to represent the rope.

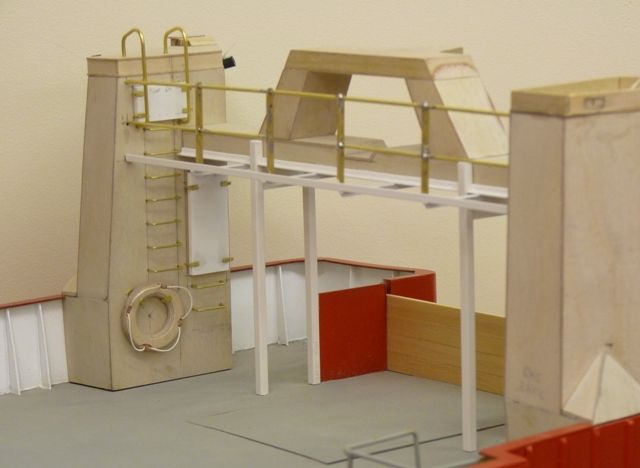

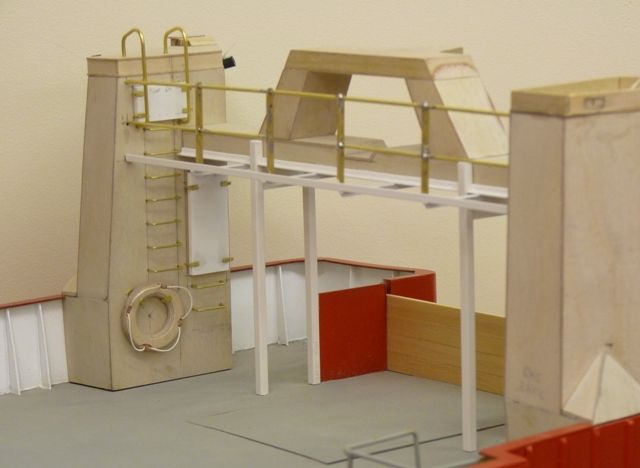

The lifebelts need a bit of tidying up, painting and a short length of reflective tape wrapping round them in 4 places. However they are good enough now to allow me to make up the mounting brackets on the side of the gantry.

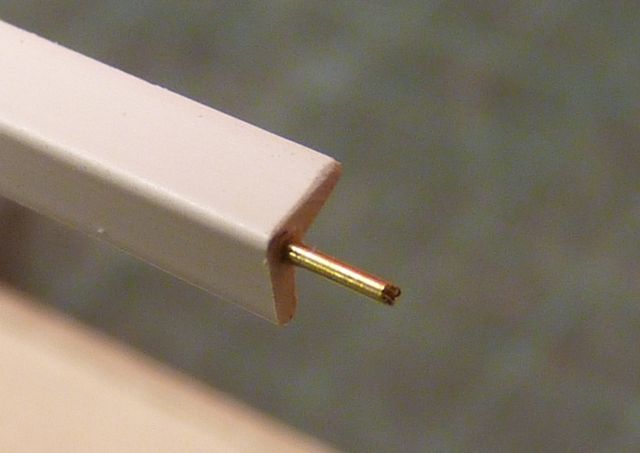

As you can see I have also made up the railings along the walkway, using brass wire and stanchions. I have also made the right hand auxiliary engine exhaust using a piece of 6 mm aluminium rod, drilled out to look like a tube. I did try to make it from brass tubing but could not get a tight enough bend in it. I don't yet know how I am going to make the main engine exhaust as that is about 12 mm in diameter and needs an inner bend radius of about 20 mm so it will be more difficult to make. Anybody any ideas?

Finally I have added the outer hanging pulley which the trawl warp runs over. I happened to have three of just the right size, if not exactly the right shape, which were originally deck pulleys on my wife's Marblehead. However they will do for now unless I can find something better.