Stephen Bowles’ lightship model

I am relatively new to boat modelling, but have learnt that you start thinking of your next project a long time before the current one is finished. So, the Brave Borderer scratch build project was incomplete when I started Spurn LV14 (LV means Light Vessel) and why this one? Well, I wanted something unusual and challenging and also she was moored in Gloucester Docks close to my home, so could be easily visited. Spurn is currently named Sula, being owned by Jan and Agnes van der Elsen, who converted her to a centre for complementary healthcare and Buddhism study.

Spurn was built in 1959 in Beverley, Yorkshire, and stationed at Spurn Head until 1985. Once decommissioned, she has been bought and variously moored in Guernsey, Conwy, Milford Haven and Bantry Bay, before being bought by Jan and Agnes and moored at Gloucester in 2010, having had a somewhat nerve-wracking journey up the Sharpness Canal.

Enjoy more Model Boats Magazine reading in the monthly magazine.

Click here to subscribe & save.

The model

Having decided upon a subject, some drawings are needed. Hull Maritime Museum had the original drawings, but could not copy them and Hull is also a long way from my home. Fortunately, Jan van der Elsen had a general arrangement drawing which was too large to be copied, but was photographed and a tracing of the deck plan and other sections was made. There were no full depth hull cross-sections, so after some deliberation a waterline model seemed to be a good way forward. Domestic workspace is limited to the cupboard on the house upstairs landing, Photo 1, so a 1:72 scale model with a length of 550mm seemed like a good idea. Photocopier rescaling of the tracings produced waterline and deck drawings and a mid-line section.

Construction

A styrene hull, built around a core of formers with carved balsawood bow and stern sections was the intended method of construction. Photos of the full-size vessel were essential to obtain the shapes required, which may not be perfect, but are a fair approximation.

The hull framework up to main deck level was made from balsawood as in Photo 2. On the top of this was fixed the main deck , this being from sheet styrene as in Photo 3. In this last picture you can also see the start of the North Sea base on which it will eventually be properly displayed.

Temporary balsawood formers were fixed with tape, fore and aft above the main deck to create the shape of those bulwarks, but these would be removed after cladding with styrene sheet, Photo 4. I had no idea if this would work, but that’s the joy of scratch building isn’t it? 0.5mm styrene sheet was used for the hull shell plating, superglued to the lower sub-structure, after first drilling holes for the portholes, Photo 5. As you can see, the bow and stern sections used shaped pieces of sheet styrene cut to follow the hull lines and with insets to allow the curves to be formed. The temporary balsawood pieces were then carefully removed and the result was not perfect, but it had a battered look to the hull, so it was at this stage that I decided to make the model ‘weathered’ a bit, as if moored in the North Sea.

Cutting and fitting the bulwark support pieces was fiddly, but once capped with a rail, it looks okay. They are not 100% in their correct positions, but without a drawing it was the best that could be done. The hull was sprayed with an acrylic red paint , Photo 6, and later had its black areas picked out by hand.

Main deckhouse structure

The deckhouse unit was constructed of styrene sheet, its profiles shaped to follow the deck lines and drilling the portholes in it produced a tiny raised edge which mimicked the welds on the original vessel. This main cabin was loose fitted and some hatches etc. made, but when these were glued to the main deck it was discovered that the deckhouse unit was about 30mm too long, so a ‘cut and shut’ operation was performed on it and the resulting joint filled. Styrene rod handrails and associated brackets were made, fitted and painted black. Some of the access doors are of 1mm mahogany, that re set in to the deckhouse sides, with their panelling drawn with a fine black pen. The porthole glazing is clear acrylic glued to their insides, but painted dark grey. The deck was brush painted a blue/green colour and suddenly the whole thing started to look like a lightship as in Photo 7, here on its painted display base.

Wheelhouse, diaphone and lantern tower

The small twelve sided wheelhouse (I will call it that, although of course the lightship was not self-propelled) has a roof-mounted diaphone. A template was drawn using CAD, to make the 2mm base and the 12 sides of the wheelhouse cut, with window openings in them. These were all glued to the base piece, their edges chamfered to obtain a reasonable fit. It was then hand painted and the ladder up to the diaphone deck, cut and fitted.

The diaphone consists of two hemispheres mounted back to back. This was a bit of a conundrum to make, but a mould for making different size hemispheres for paper craft was discovered and by pressing Milliput into the mould, hey presto, two perfect shapes which could be glued back to back with styrene struts between them and its cone-like roof.

The lantern is a major feature of a lightship, no surprise there! The lower part of it was easily formed from a large shampoo bottle top, clad in 0.25mm styrene pieces fixed to it with double-sided tape. After some thought and searching for the right materials, the lantern was created by using 1.5mm T-section styrene for the uprights between the glazing panels, all fixed between lower and upper rings and each clear panel cut from redundant semi-rigid food packaging. The vertical bars were painted red on their outsides, but left white inside. The roof was a circle piece cut from sheet styrene, a radial cut made and then folded in on itself to create the shallow cone.

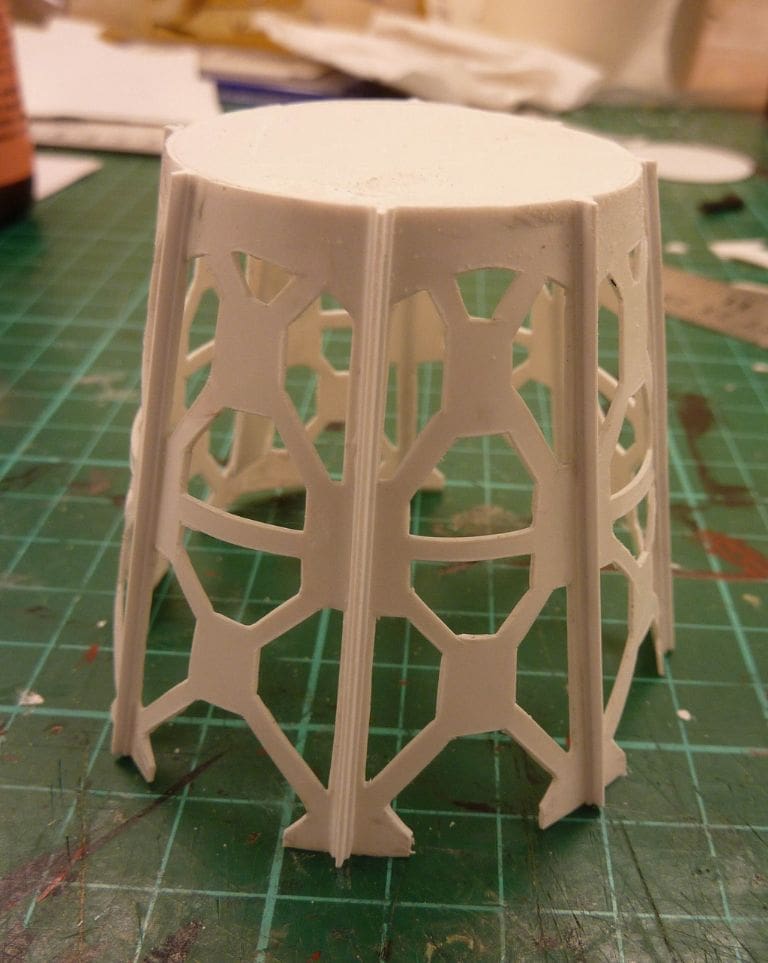

The supporting tower is a truncated cone of latticework. This was carefully drawn on paper that was stuck to 0.5mm styrene, Photo 8, and each lattice piece cut out. A lot of work here, but it is a major feature, so well worth the effort, Photo 9. You can see in this last picture some reinforcing T-pieces of styrene fixed vertically between each lattice part. The railings on its circular walkways were made from brass wire, glued at the joints with thick superglue, which produced reasonably realistic stanchion balls.

Last detail parts

The mooring clamps and their chains are missing from Sula as now at Gloucester. One such device, which had been removed during the refit is at Sharpness Dry Dock, Photo 10, so a quick visit to measure and photograph it meant that they could be easily modelled,. The anchor windlass is, I am sorry to say, built using modeller’s licence from photos and the somewhat sketchy plan. The two stepped steel masts are of shaped dowel, with toothpicks as their spars. The various small deck fixtures are from styrene section and sheet and the ventilator cowls were also moulded from a paper craft mould and Photo 11 is of the complete model on its painted display base.

Conclusion

The model overall doesn’t look too bad in my humble opinion. It has been fun making it in the cramped workshop cupboard at the top of the stairs and has made for a nice, but slightly unusual, display model. Just as Spurn was finished, news came through that Sula, ex-Spurn, was now up for sale again, its owners now intending to build a non-afloat Buddhist temple. So this old lightship may soon be on the move again from Gloucester.

Enjoy your hobby – Stephen Bowles

Stephen is a retired architectural technician, living in Newnham on Severn, Gloucestershire. He has had a spate of electric guitar making which is expensive and now Spurn is his third boat, after Bluebird of Chelsea and Brave Borderer. He is currently doing a Riva Aquarama before returning to Brave Borderer to fit it for r/c. He likes scratch building and is not really routinely interested in making working models, hence no club membership. As he says, Stephen is not a perfectionist, just doing the best he can for his own satisfaction – Editor.