Richard Simpson with Part One of six short articles on steam

Forward

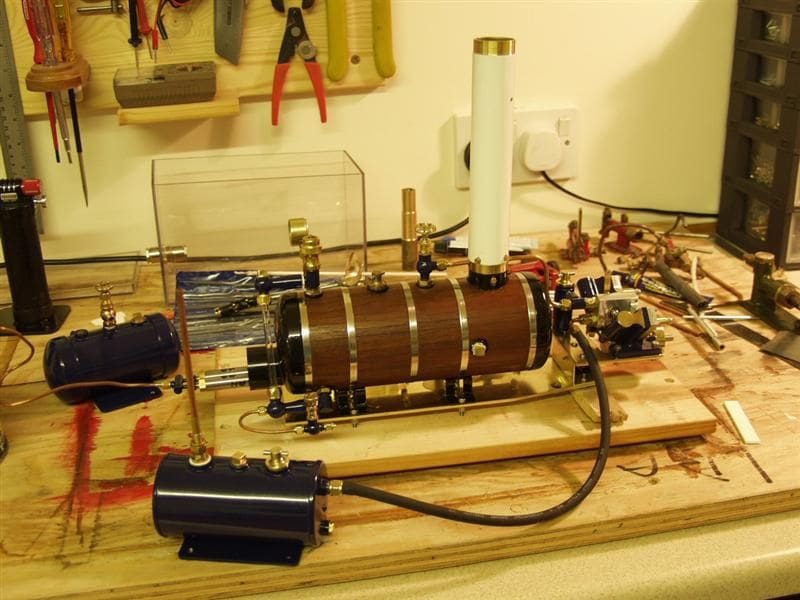

Have a look around the pond on a Sunday morning and take in the types of boats that are there for everyone to have a look at. You will find everything from sail to scale to fast electric, but how many of them are steam powered? Usually very few, but which models generate the most interest? Of course the steam driven models as in Photos 1 and 2.

Enjoy more Model Boats Magazine reading in the monthly magazine.

Click here to subscribe & save.

Going back a few years, electrical engineering always seemed to have a level of mystery and unknown attached to it that could only be fathomed by slightly eccentric engineers whose cigarette ash became so long as it hung from their mouth that it could only be held there by magnetism. They peered at us over the top of spectacles that looked like they had been cut directly from the bottom of particularly thick milk bottles and did absolutely nothing to alleviate our fear of the dark art of electrical engineering. As far as we were concerned at college, marine engineers dealt with huge engines and their associated machinery, including auxiliary boilers, and they were only really happy when they were swinging around on the end of extremely large sledge hammers, trying to hit extremely large spanners, preferably in heavy seas to give the story in the pub back home considerably more credibility.

Nowadays, I regularly smile as I watch my friends in the model boat world relate the intricacies of motor sizes, battery characteristics, crystal compatibilities, the best micro-receiver to be used with a particular servo, sound and smoke generating systems, both of which follow the speed of the motor, and last but certainly not least lighting systems that would put most coastal craft to shame. I have to say, it seems to me that the development of model boat sound systems seems to be chased with a degree of enthusiasm that has far outstripped any sense of reality. The cacophony of steam reciprocating engines, V8 diesels, fog horns, guns and telegraph bells that emanate from most ponds on a Sunday morning, is completely out of proportion with reality and I can safely say that the majority of noise coming from most harbours around the world at a similar time usually comes from the seagulls Even ships passing within a few feet of your own vessel do not actually generate much noise.

However, mention the word STEAM to the gathered masses and all the sound systems appear to shut down by use of a common switch and everyone nervously looks around to see just who it was who swore so profoundly. Steam now seems to hold that sacred ground previously held by electrical engineering, and most model boaters smile nervously as they walk past a boat being prepared on the bank with real steam rising from the funnel, as opposed to water vapour generated by the latest in high frequency nebulisers.

So why do we get ourselves into such a state over steam? Why do we plug our 10amp motor to a large motorcycle battery, turn it on and watch it flying around the pond without a care in the world, but consider a steam plant to consist of items that we dont even want to consider learning anything about, never mind using ourselves. Strangely enough, a steam system can actually be likened very closely to an electrical system, with pressure in a steam pipe being very comparable to voltage and the flow of steam almost directly comparable with current. People are terrified of the potential damage an exploding boiler could do, but it doesnt cross their minds that the battery in their model has just as much potential if the pressure is similarly released.

Aims

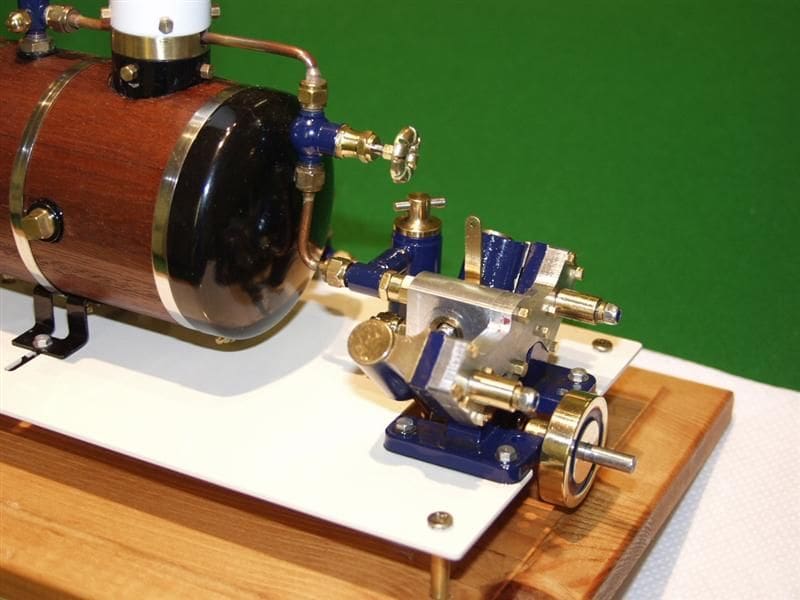

What I would like to do therefore, is try to pull away some of the mists that surround the whole idea of steam in a model boat and maybe even encourage a few people to have a go at it. The articles will cover such subjects as the boilers, Photo 3, the engines, Photo 4, auxiliary equipment, assembling a system to suit your requirements, looking after the plant and common problems. I find it very disappointing to hear so frequently nowadays of a modeller who has purchased a steam system, filled it with water and gas, ignited it and when up to pressure watched the engine flying around at a satisfying blur until such point as it stops and refuses to ever move under its own power again. Complaints to the manufacturer invariably lead to discussions on care and use and the modeller ends up with a very expensive pile of a very pretty, but quite useless assembly of metal.

I want to relate particularly to modern and available equipment currently manufactured, so that anyone can follow what is being discussed and purchase the same products. Boilers, engines and all auxiliary equipment can be purchased off the shelf from UK suppliers or from abroad, but as with so many things of a technical nature, support is also a consideration. It may look attractive to purchase a foreign manufactured plant which might have an encouraging price tag, but when you want to ask a question, is it worth being able to pick up a phone and talk to the vendor, or are you happy to wait for the answer to an e-mail?

I will be using my own recent steam plant as an example, as during its construction I have come across most of the common problems associated with modern model steam systems and have developed my own methods of dealing with them, some of them tried and tested and some of them a bit more innovative.

Pre-planning

You will find that some manufacturers only supply some items, so do you want to buy a boiler from one and an engine from another, or do you want the reassurance that the two are designed to work together and have come as a package from the same manufacturer? What about all the auxiliary bits you need? What thread system do you want to use? Lets have a think about some basic pre-planning before we even consider looking for the credit card. If your better half has even an inkling that you are thinking along the lines of a steam system and she has chatted to your friends in the model boat world about the costs of such a venture, you will probably find it difficult to get the credit card off her anyway. You may as well spend some time planning, until she has decided that you have given up on the idea, then you can grab the card, buy all the big bits you want in one swoop before she has realised what has happened, and wait for the boxes to arrive. However, make the most of this opportunity, because you wont get another one for a long time.

Lets start with a very basic part of the planning and original thinking. Do you realise that a steam plant is not Plug and Play? My own aim is always to have a plant that operates as reliably as an electric plant, but to achieve this I have had to put a lot into its design and I will always have to put a bit more into its operation. It needs oiling, it needs condensate removing, it needs gas filling and it needs water filling. All require a lot more than operating a switch and if this amount of involvement is not for you then you are best staying away. I am certain that there are a number of modellers who have bought into the idea of a steam plant, but expect to drop it in the boat, fill it up and let it go and they will be able to continue to do this for years to come. If you are prepared to learn a bit about steam, what it involves and are willing to do that bit more at the pondside, then you can go to the next stage of the planning.

If you are committed to a steam plant, and I sometimes feel I should have been committed for even thinking of my own plant some time ago, then you need to generate a general idea of what you want. You should have an idea by now of what type of model you want to be powered by the plant, so you should be deciding whether you want a kit or are you going to scratchbuild it. Do you want a tug, a coaster, an open launch or something individual? Only you can decide how much you want to put into this project and what your own capabilities are, but if the steam plant is new for you I would recommend keeping the model relatively simple. I would also suggest a model that easily lends itself to steam, so either an open launch or a large hull would be better. Dont confine yourself to a tightly fitting arrangement which is going to try your patience every time you take it out to the pond. You want to make it simple to use, simple to build and simple to maintain. My own project uses a Mount Fleet kit of the steam coaster Ben Ain, which was possibly not the easiest to start with, Photo 5. I have had to modify the kit drastically to enable removal of the bridge unit and I couldn’t get the plant as far back as I needed for the boiler flue to line up with the funnel, so it required quite a lot of modification to the steam plant. Try to avoid these things in the pre-planning stage and stay with a nice big open hull, Photo 6.

Long before you get to the complexities of designing your overall plant you need to think about what you want your model to incorporate, which will be based on how you want to operate it at the side of the pond. At one extreme end of the scale you could have a fully functioning automatic boiler control system with on board feed pumps, feed tanks, gas regulating valves etc., or at the other end, a very simple continuously running single cylinder engine in a boat, which you have to take out of the water to refill the boiler when the water level gets low. As with most things, your own requirements will fall somewhere in the middle. I decided that I wanted a fully controllable engine so it would have to be double acting and a twin cylinder, I wanted it to take up as little space longitudinally as possible to enable the boiler to be placed as far back as I could get it, so a Vee-configuration engine was the most likely. I wanted to be able to fill up the boiler without having to vent off steam pressure, but I didnt want automatic level control because I think they are an unnecessary complexity and the engine driven pump saps available propulsion power. Also I am going to have to bring it into the bank regularly anyway to empty the separator, so I decided on a manual on board pump and feed tank, Photo 7.

These basic pre-planning decisions eventually gave me a direction for the model and enabled me to think a bit more about what pieces I needed to incorporate into the design. I knew I needed a feed tank, which would be built into the bow, an on board gas tank, an oil separator, horizontal boiler with a flue at the aft end, a V-Twin engine and a few other bits and pieces of control and radio gear. The next step was to design in a bit more detail how this lot would go together, Photo 8, so for the next article I want to have a more specific look at the individual components and what options are out there for your project.